Have you ever broken your soldering iron while repairing something? Perhaps you were about to mend something when you discovered that your soldering iron was damaged. It’s particularly inconvenient when you’re working on an urgent repair or working late at night since stores are closed.

You can even use a 5V soldering iron that you’ve broken to repair it.

All you need is some nichrome wire, a connector, and a few other tools that you probably have lying around your house.

This guide will show you how to make a soldering iron without nichrome wire so that you can continue your repairs uninterrupted.

In this blog post, soldering experts are going to show you how to make a soldering iron without nichrome wire. Nichrome wire is often used in the construction of a soldering iron, but it can be difficult to find and expensive. In this tutorial, we will show you how to use an old light bulb as a substitute for nichrome wire. This is a great project for anyone who wants to learn more about electronics and metalworking!

What’s A Soldering Iron?

A soldering iron is a hand tool used in welding and electronics work.

It supplies heat to melt the solder so that it can flow into the joint between two workpieces.

A typical soldering iron is composed of a heated metal tip and an insulated handle. The tip is made of copper, brass, or other metals, and it is coated with a thin layer of solder. The handle is usually made of plastic or rubber [1].

The soldering iron is connected to a power source, such as a battery or mains voltage, and the tip is heated to the required temperature by passing an electric current through the nichrome wire. Once the tip is hot enough, it can then be used to melt the solder and join two pieces of metal together.

Soldering irons come in a variety of sizes and shapes, and they can be fitted with different tips for different applications. Some soldering irons even have interchangeable tips, so that they can be used for multiple purposes.

There are many different ways to make a soldering iron, but one of the most common methods is to use nichrome wire. Nichrome wire is an alloy of nickel and chromium, and it has very good electrical resistance properties. This makes it ideal for use in electrical applications where high temperatures are involved.

Things You Would Need to Make A Soldering Iron Without Nichrome Wire:

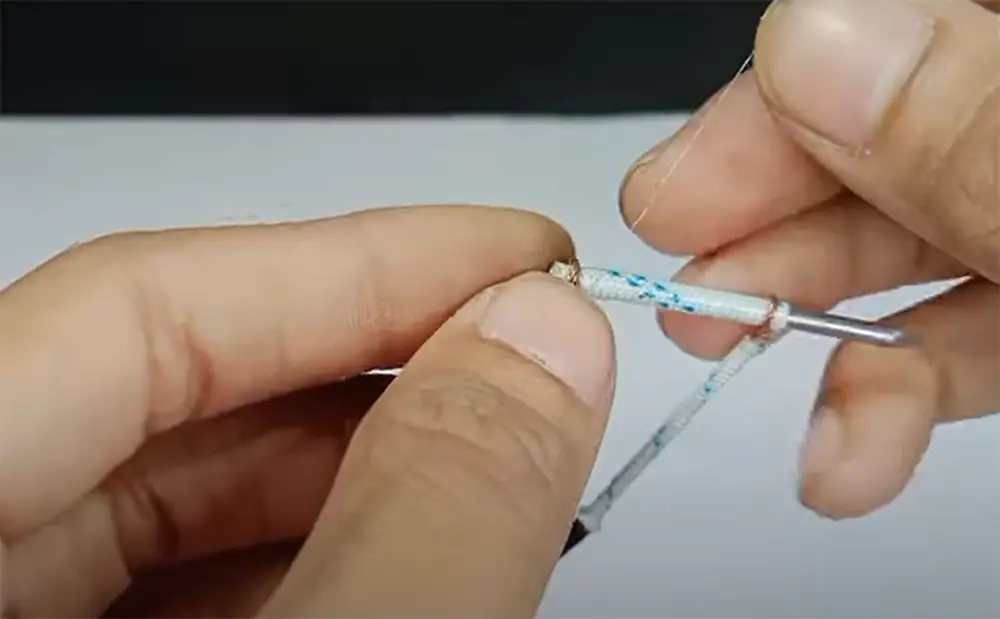

1) Syringes

You will need two types of syringes, a larger one and a smaller one. The larger syringe will be used to melt the solder, while the smaller syringe will be used to apply the solder to the joint.

A soldering iron without nichrome wire is not very different from a regular soldering iron. The main difference is that you will not be able to use nichrome wire to heat the solder. Instead, you will need to use a syringe to melt the solder.

2) Switch

You will need a switch to turn the soldering iron on and off. You can use a simple toggle switch, or you can use a more complex switch that has built-in temperature control.

The switch is used to control the flow of electricity to the soldering iron. If you are using a toggle switch, then you will need to solder the wires to the switch before you can use it. If you are using a more complex switch, then you will need to follow the instructions that come with the switch.

3) Wooden Piece

You will need a small wooden piece to attach the syringe to. Cut a small hole in the middle of the wood, big enough to fit the syringe snugly.

4) Some Wires

You will need some wires to connect the switch to the syringe.

If you don’t have any nichrome wire, don’t worry- there are other materials that you can use as a substitute.

For example, thin copper wire or even aluminum foil can be used in place of nichrome wire. Just make sure that whatever material you choose has high resistance so that it doesn’t overheat and damage your soldering iron.

5) A Glue Gun

You will need a glue gun to attach the wooden piece to the syringe. Make sure that the glue gun is unplugged and cooled before proceeding. Attach the wooden piece to the back of the syringe plunger. Allow the glue to dry completely before moving on to the next step.

6) Pliers

You will need a pair of pliers to help you bend the wires. Make sure that you do not overheat the wires or they will break.

7) 12-Volt Battery

You will need a 12-volt battery to power the soldering iron. This can be any type of 12-volt battery, including a car battery or a marine battery.

If you do not have a 12-volt battery, you can use two AA batteries in series to create a 12-volt power source. To do this, simply connect the positive terminal of one AA battery to the negative terminal of the other AA battery. This will create a 12-volt power source.

Steps For Making The Soldering Iron Without Nichrome Wire:

Here’s another word of caution: be careful when working with the syringes [2]:

- The last step is to connect one end of the wires to the needles and the other to a battery. You may attach the switch to the wire with glue and mount it on the wooden piece;

- You may bend the needles with a plier to make working easier. It would be advantageous if you can connect the needles somewhat;

- You must now connect the wire’s other end to a battery. A 12-volt battery would be used here;

- Turn on the soldering iron and press the switch – there you have it! You may notice that the soldering iron begins to operate. Now you can give it a try and find out whether it works for you;

Now that you know how to make a soldering iron without nichrome wire, you can use it for all of your soldering needs. Just be sure to follow the instructions carefully and always use caution when handling hot solder.

Tips For Users:

- First, you’ll need to choose a material that can withstand high temperatures;

- Second, you’ll need to find a way to heat the material evenly;

- And third, you’ll need to be careful not to overheat the material and cause it to catch fire;

- Finally, be sure to keep an eye on the temperature of the material. If it starts to get too hot, turn off the heat source and allow it to cool down before continuing;

With these tips in mind, you should be able to make a soldering iron without nichrome wire without any problems.

FAQ

What can I use instead of nichrome wire?

One of the most popular materials for making a soldering iron is copper. Copper is an excellent conductor of heat, which means it heats up quickly and evenly. It’s also relatively inexpensive, making it a good choice for those on a budget [3].

Another material you may want to consider is aluminum. Aluminum is also a good conductor of heat and is less likely to catch fire than copper. However, it’s important to note that aluminum melts at a lower temperature than copper, so you’ll need to be careful not to overheat it.

No matter what material you choose, the most important thing is to find a way to heat it evenly. Otherwise, you run the risk of causing the material to catch fire or melt unevenly. One way to do this is to use an electric stovetop or hot plate.

Another option is to use a butane torch. If you’re using a torch, be sure to keep the flame moving so that it doesn’t stay in one spot for too long.

How do you solder a soldering iron without wire?

If you don’t have nichrome wire, you can still make a soldering iron. All you need is some copper wire and a few tools. With a little bit of effort, you can create a soldering iron that works just as well as one with nichrome wire. Here’s how:

- First, gather your materials. You’ll need some copper wire, a crimping tool, and a heat source. You may use an old soldering iron for your heat source, but you could also use a candle or lighter;

- Next, use the crimping tool to attach the copper wire to the tip of the soldering iron. Make sure that the connection is tight so that there is good contact between the two materials.

- Now, apply heat to the wire. It may take about 30 seconds for the wire to reach a soldering temperature. Once it’s hot enough, you can start soldering;

If you don’t have nichrome wire, don’t worry – you can still make a perfectly good soldering iron without it. With a little bit of effort, you can create a perfectly functional soldering iron that works just as well as one with nichrome wire. So go ahead and give it a try! You might be surprised at how well it works.

What can I use if I don’t have a soldering iron?

Anything that can heat metal to the melting temperature of your solder (between 400°F/200°C and 700°F/370°C) may be used. Lighters fueled by butane are the most effective. Candles, oil lamps, alcohol burners, and even open campfires can also be utilized [4].

If you’re using something like a lighter, the first thing you’ll need to do is find some way to hold your metal. You can use anything from alligator clips to clothespins. Once you’ve found something that works, clip it onto the piece of metal you’re going to be soldering.

Now it’s time to heat up your metal. Put the flame of your lighter on the joint between the two pieces of metal and wait for the solder to melt. It should only take a few seconds. If it’s taking longer than that, turn up the heat.

Once the solder has melted, you can remove the flame and allow the joint to cool.

If you’re working with sensitive electronics, you’ll need to be careful not to overheat the components. This can damage them and cause them to stop working. If possible, find a heat sink to attach to the component before you start soldering. This will help dissipate the heat and protect your electronic parts.

Where can we find nichrome wire at home?

Neither salt water nor electricity had any effect on the wires. It is also rather helpful as a heating element. As a consequence, it has significant application in commercial goods and domestic tools. Nichrome wire coils are utilized in hairdryers, ovens, storage heaters, and toasters among other things.

You can find nichrome wire in any hardware store, or even in some online stores. However, before you buy nichrome wire, make sure to check the quality of the wire. There are many fake wires out there, so it’s important to be careful.

Once you have your nichrome wire, the next step is to create a coil.

To do this, you will need a drill and a piece of cardboard:

- First, make a hole in the center of the cardboard with the drill;

- Then, start winding the nichrome wire around the hole until you have a coil with about 20 turns;

- Once you’re done, cut off any excess wire and tape down the end of the coil;

You may be able to find an old electric heater element or a length of Nichrome wire at a salvage yard or junk shop. If you have access to a welder, you could make your own heating element from a piece of scrap metal.

If you can’t find any Nichrome wire, there are other ways to heat up the metals so they will fuse together. You can use a propane torch, an alcohol lamp, a butane lighter, or even a candle. Just be sure that whatever you’re using doesn’t get too hot and melt the metals you’re trying to join together.

Can you solder with Super Glue?

An insulating effect may be had with a combination of epoxy resin, polyester resin, and cyanoacrylate glue (super glue). It’s being used to add extra grip on wire-wrap boards by some people. It isn’t acting as a solder – it’s just preventing the connection from coming undone because it’s not providing an electrical connection. Plastic tape can serve as an insulator [5].

Can you use a paperclip as solder?

The answer is yes and no. If you’re new to soldering, or just need to solder a quick repair, then a paperclip can be used as an emergency solder.

All you need is a lighter and some pliers [6]:

- First, straighten out the paperclip so that it’s nice and flat. Then, use the pliers to twist one end of the paperclip around the other until it’s tight – this will act as your handle;

- Next, heat up the twisted end of the paperclip with the lighter until it’s red hot – this could take anywhere from 30 seconds to a minute;

- Once it’s hot enough, touch it to the pieces of metal you want to join together and hold for a few seconds until the metal melts and joins together;

And that’s it! You’ve successfully soldered without using any solder or soldering iron. Of course, this method isn’t ideal for every repair job – but in a pinch, it’ll do the trick.

What can be used as solder wire?

Solder wire is typically made of tin and lead, but there are also lead-free options available.

The most common diameter is 0.031 inches (0.79 mm), although it can range from 0.020 inches (0.51 mm) to 0.125 inches (0.32 cm) [7].

If you don’t have any solder wire on hand, you can use a pencil lead as a substitute. Pencil lead is made of graphite, which has a similar melting point to tin and leaded solder alloys. Just be sure to use a fine-point pencil so that the lead is thin enough to work with.

Can you use tin foil for soldering?

You can use tin foil for soldering, but it’s not the best choice. Tin foil is a good conductor of heat, but it doesn’t have the same strength as nichrome wire. This means that your soldering iron will be more likely to break if you use tin foil.

Another downside of using tin foil is that it doesn’t last as long as nichrome wire. You’ll need to replace your tin foil much more often than you would need to replace nichrome wire.

Overall, it’s best to avoid using tin foil for soldering. If you must use it, make sure to get the highest quality tin foil you can find, and be very careful with your soldering iron.

Useful Video: How to make soldering iron without nichrome wire

References:

- https://www.aboutmechanics.com/what-is-a-soldering-iron.htm

- https://handtoolsforfun.com/how-to-make-a-soldering-iron-without-nichrome-wire/

- https://electronics.stackexchange.com/questions/138334/hot-wire-cutter-can-i-use-copper-wire

- https://www.instructables.com/How-to-Solder-Without-Electricity-or-a-Soldering-I

- https://electronics.stackexchange.com/questions/3146/soldering-substitutes

- https://reprap.org/forum/read.php?13,67134

- https://electronics.stackexchange.com/questions/518349/substitute-for-solder-wire-and-flux

If you ask me, the versatility of soldering irons is impressive. With various sizes, shapes, and interchangeable tips, they adapt to diverse applications. Utilizing nichrome wire, an alloy with excellent electrical resistance properties, is a common and effective method, especially in applications requiring high temperatures.

If you ask me, the versatility of soldering irons is impressive. With various sizes, shapes, and interchangeable tips, they adapt to diverse applications. Utilizing nichrome wire, an alloy with excellent electrical resistance properties, is a common and effective method, especially in applications requiring high temperatures.

Leave a Reply