It’s no secret that soldering is an essential skill when it comes to building electrical circuits. But, what if you don’t have the skills or materials for soldering? Attaching wires to a circuit board without solder can be difficult and frustrating. To make things easier for those looking for alternatives, our post today will provide step-by-step instructions on how to safely and securely attach wires to a circuit board—without any need of solder. We’ll go through the different methods available such as crimps and ties, explain each in detail, and even recommend some supplies if needed — all so that you never have to worry about struggling with soldering ever again! So stay tuned; let’s start wiring up your circuit boards without any hassle at all.

How to Attach Wires to a Circuit Board Without Soldering?

Using Alligator Clips

Using alligator clips is a simple method for connecting wires to a circuit board without the need for soldering. Alligator clips are small clamps with two pointed metal jaws that can be used to make electrical connections. To use them, simply clamp one end of the clip onto the wire and then fasten the other end onto the circuit board.

Using Wire Wrap Connectors

An alternative way to attach wires to a circuit board without using solder is by using wirewrap connectors. This technique involves threading a predetermined length of insulated copper wire around a metal post. As the wire is wrapped around the post, it forms a connection that creates an electrical bond between the two components. This technique is especially useful when connecting to small, delicate circuit boards where soldering would be difficult or impossible.

Using Screw Terminals

To avoid soldering, an alternative method for connecting wires on a circuit board is by using screw terminals. This method involves drilling holes into the circuit board and attaching screws with nuts onto them. The wires can then be connected by wrapping them tightly around the screws and securing them in place with the nuts. Be sure to use insulated cables since this method does not provide any kind of protection from shock or other hazards.

Using Electrical Tape

The only remaining option to attach wires to a circuit board without using soldering is to use electrical tape. This method involves wrapping the wire tightly around the circuit board and securing it in place with electrical tape. Although this provides an adequate connection, it is not as secure or long-lasting as other methods. It is also important to note that any exposed wires should be covered with additional layers of insulation in order to avoid any potential hazards.

Using Hot Glue

Hot glue can be used as an alternative method to solder wires onto a circuit board. This is a simple but effective method that involves applying a small amount of hot glue onto the component and then pressing the wire into it. The hot glue will create an electrical connection while also providing some additional protection from vibrations or shock. However, it is important to ensure that the wires are secure before using any other type of electrical connection as they can easily come unglued if not properly secured.

Crimping

Finally, crimping is another method for attaching wires to a circuit board without soldering. This technique involves using a special tool to compress the wire onto the component or post. The compressed connection creates an electrical bond that is strong and secure enough for most applications. Like all other methods, it is important to use insulated wires when crimping in order to ensure maximum safety from shocks or short circuits.

Using any one of these methods will allow you to safely attach wires to a circuit board without soldering. Remember to always confirm each connection before powering up your device and never attempt to forcibly disconnect two components that are fused together with solder. By taking the necessary steps and following proper safety protocols, you can easily connect your components without worrying about damaging any components or creating a hazardous situation.

How To Fix A Broken Wire On A Circuit Board?

Fixing a broken wire on a circuit board is possible without soldering. This can be done using heat-shrink tubing and insulated electrical tape. First, cut away any damaged insulation around the break in the wire. Then, slide a piece of heat-shrink tubing over the wire ends so that they overlap slightly. Use an appropriate size of heat-shrink tubing so that it fits snugly over the wires when heated. You may also want to apply some electrical tape around the overlapping wires for extra protection.

Next, use a hair dryer or lighter to carefully heat the tubing until it shrinks tightly around the wires and provides an airtight seal. Once cooled, your connection should be secure enough to use without soldering. As an added measure, you can use electrical tape to further secure the repaired area.

If your wire does not have any insulation around it at all, you can still make a connection without soldering by twisting the two wires together and then wrapping them in electrical tape or heat-shrink tubing. This method is usually only suitable for low voltage circuits since there is no guarantee that the connection will be electrically sound.

No matter which method you choose to use, always take appropriate safety precautions when working with electricity. Make sure that all exposed connections are insulated and away from potential hazards like water or other fluids. With proper care and maintenance, your circuit board should remain safe and functional for years to come!

Is It Safe To Use Glue Instead Of Solder?

Using glue instead of soldering to attach wires to a circuit board is generally not recommended due to the risk of creating an unreliable connection. The heat and pressure associated with soldering creates a tight bond between the wire and the board, ensuring that there won’t be any loose connections or shorts that could cause electrical failure. Glue, on the other hand, does not provide this level of security as it cannot create a reliable electrical bond between the two pieces.

Additionally, using glue can make it more difficult for you to change or adjust any components in your circuit board assembly down the line because both sides would need to be re-glued if they ever become detached.

All together, while using glue instead of soldering may seem like a simpler and easier option, it is not recommended as the risk of electrical failure is too high. If you need to attach wires to a circuit board without soldering, consider using crimp connectors or ferrules instead. These provide a more secure connection than glue—without the need for heat or pressure from a soldering iron. Ultimately, these are much safer options that will deliver reliable connections with minimal effort.

Is Hot Glue Bad For Electronics?

Hot glue is often used to attach wires to a circuit board without soldering, but it’s not the best alternative for this task. Although hot glue can provide a temporary fix, it does not provide the same level of security and durability that soldering does. Over time, vibrations and temperature changes can cause hot glue to break down and become brittle, potentially leading to a loose connection or an electrical short on your circuit board. Additionally, hot glue may contain chemicals that can damage sensitive electronic components over time. For these reasons, hot glue should generally be avoided for attaching wires to a circuit board without soldering.

For those who wish to avoid soldering altogether, there are several other methods that might be suitable for temporary, low-power projects. Examples include twist-on connectors, clip leads, and various types of electrical tape. While these methods may not provide the same security or durability as soldering, they can be a good alternative in certain situations.

Ultimately, the best option for attaching wires to a circuit board without soldering is to use solderless connectors. These are specially designed clips that are inserted into plated holes on your circuit board and then tightened with a screwdriver. They provide excellent connections with minimal effort and time, making them an ideal solution for most applications.

FAQ

How do you secure wire without soldering?

Soldering is not the only way to secure a wire onto a circuit board. You can use crimp connectors or screw terminals, which are available in metal and plastic varieties. Crimp connectors come with insulated sleeves that you place around the wires before inserting into the connector. The connector is then compressed with your fingers or pliers to ensure a good connection. Screw terminals involve fastening a terminal block over the wire and tightening it down with a screwdriver, while plastic variants require no tools—the terminal cover snaps into place when pressed together. Both methods provide reliable electrical connections without the need for soldering.

What materials do I need to attach wires to a circuit board?

For solderless wiring, you will need crimp terminals or screw terminals, depending on the type of connection you are making. In addition, if using crimp connectors, you will need insulated sleeves to place around the wires so they fit properly in the connector. Finally, for screw terminals, you may need a wire cutter and a small flathead screwdriver to secure the terminal block over the wires.

What are some advantages of attaching wires without soldering?

Soldering can be time consuming and require specialized tools. Attaching wires without soldering is quicker and easier—it requires no special equipment (except perhaps a pair of pliers) and can be done with just your fingers or a screwdriver. Furthermore, non-soldered connections have better tension than solder joints, which can reduce the risk of electrical faults. In addition, non-soldered connections are easier to repair and replace if needed. Finally, non-soldered connections allow for more flexibility in terms of how and where you attach wires on your circuit board.

Can I use solder instead?

Yes, soldering is still a viable option when attaching wires to a circuit board. However, it requires more specialized tools such as soldering iron or heat gun and flux paste. Furthermore, it is not as easy to remove or replace a soldered joint if needed—you would need to reheat the solder and potentially damage the surrounding components in order to do so. For these reasons, many people prefer using crimp connectors or screw terminals over soldering for their wiring projects.

Are there any safety considerations when attaching wires?

Yes, it is important to consider safety when wiring your circuit board. Make sure all exposed conductors are properly insulated with appropriate materials such as heat shrink tubing or electrical tape. Also, be sure to double-check the connections before powering up the circuit board—incorrectly wired components can cause short circuits and potential fires. Finally, use caution when using pliers or screwdrivers around your electronics in order to avoid shocks and other accidents.

What can I use instead of solder on a circuit board?

An alternative to soldering on a circuit board is crimping. Crimping uses specialized tools to press two metal pieces together, allowing for electrical contact without the need for solder. Additionally, some special crimp terminals can be used to attach stranded wire directly to components on the circuit board without needing to add any additional elements like heat shrink tubing or heat shrink boots. This method also eliminates the need for additional soldering and provides an extremely strong connection between the wire and component.

Another option is using low-temperature thermoplastic adhesive systems, such as those made by 3M or similar companies. These adhesives are designed to bond conductive materials such as wires or traces on a circuit board at room temperature without requiring heat or pressure. While these adhesives can be time-consuming to work with, they provide a good alternative to soldering in certain applications.

Finally, special mechanical connectors called “jumper wires” are available that allow for the connection of two components or traces on a circuit board without needing any additional tools or processes. These jumper wires are essentially tiny metal bridges that bridge the gap between two points on a circuit board and complete an electrical connection. They come in various sizes and configurations and can be connected simply by pushing them onto the desired locations on the board.

Can I use superglue instead of solder?

Using superglue instead of solder is not recommended when attaching wires to a circuit board. While superglue may temporarily hold the wires in place, it will not provide an electrical connection between the components on the circuit board. Furthermore, as time passes, the glue will lose its sticking power and eventually come apart. This could cause a short-circuit or other damages to occur and compromise the functioning of the device. Soldering is much more effective than superglue when it comes to wiring a circuit board. Solder provides strong mechanical bonds for conductors alongside making sure they are electrically connected too.

Can you tape wires instead of solder?

Taping wires instead of soldering is not recommended. Tapes may help you quickly bundle the wires together, but it does not provide a strong enough connection between them and the circuit board. This leaves them vulnerable to damage from vibrations or jerks that can cause the loose connections to eventually break apart. Additionally, when exposed to humidity or water, electrical tapes will tend to fail more quickly than solder. For optimal protection against mechanical and environmental damages, it is best to use solder when attaching wires to a circuit board.

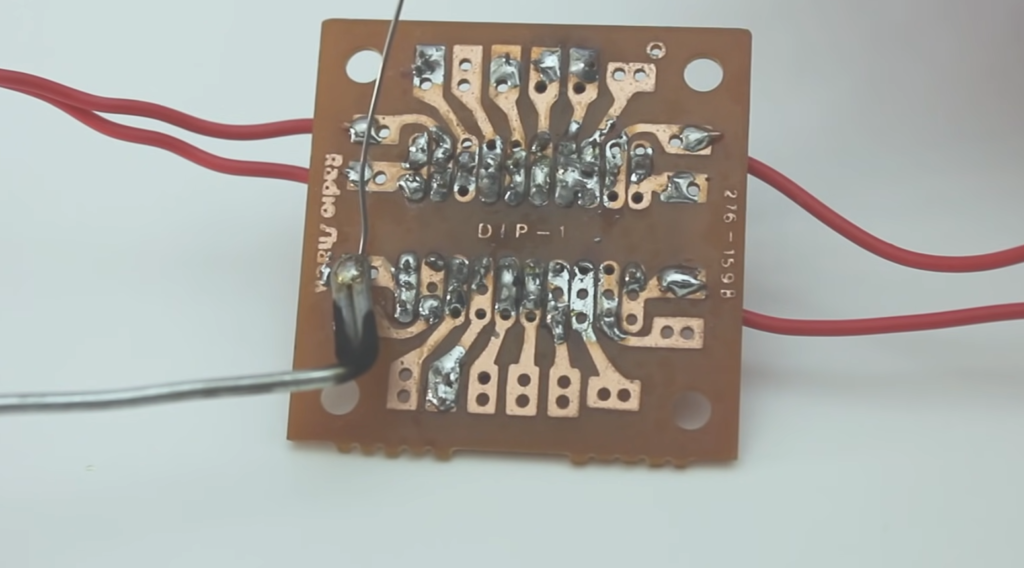

Useful Video: How to Solder a Wire to a Circuit Board

Conclusion

Attaching wires to a circuit board without soldering is possible with the use of crimp connectors, terminal blocks, and various other types of connectors. Although this method may not be as reliable as soldering, it can still provide a secure connection for your project. The key is to choose the right type of connector for the job and make sure that all connections are properly secured with the appropriate tools. With a little bit of preparation and care taken during installation, attaching wires to a circuit board without soldering can be done correctly and safely.

References

- https://www.circuitsgallery.com/how-to-attach-wires-to-a-circuit-board-without-soldering/

- https://toolsweek.com/how-to-attach-wires-to-a-circuit-board-without-soldering/

- https://www.instructables.com/4-Ways-to-Connect-a-Wire-Without-Soldering/

- https://conqelectric.com/how-to-connect-a-wire-to-a-circuit-board-without-solder/

- https://hillmancurtis.com/solder-wire-to-pcb/

- https://www.eevblog.com/forum/manufacture/what-is-acceptable-ways-of-soldering-wires-directly-to-pcb/

Leave a Reply