Mining for gold is an age-old practice that dates back to the beginning of human civilization. In fact, it was one of the first metals ever mined by humans. Besides being used as currency, gold has also been used to create some of the world’s most stunning works of art.

Interestingly, many people are unaware that they may have small amounts of gold in their homes right now, usually found inside gadgets like laptops or TVs. If you’re curious about how to extract this precious metal at home, keep reading!

However, extracting gold from electronics at home is nearly impossible without specialized equipment. Nevertheless, you can safely extract gold from any electronic device using the minimum amount of chemicals available to everyone, without requiring special skills or gear.

Brief Summary

The article provides an overview of different methods for extracting gold from electronic devices without using hazardous chemicals. It first stresses the importance of safety, including proper handling of chemicals like cyanide and lead. The article then walks through the process step-by-step: disassembling devices, cleaning printed circuit boards (PCBs), creating an etching solution with cyanide, submerging PCBs to dissolve gold foils, filtering out the foils, and properly disposing of waste. Other chemical-free options are also discussed like using nitric acid to dissolve gold plating or fire assay to melt scraps into ingots. The article compares the efficiency, cost, and time required for methods like gravity separation, mechanical agitation, electrostatic separation, plasma technology, and bioleaching. It notes that while chemicals like cyanide can yield over 90% gold recovery, safer bioleaching and agitation methods may be preferable despite slightly lower yields. In summary, the article provides DIY guidance but stresses that inexperienced handlers should consult professionals when using hazardous chemicals for gold extraction.

How to Extract Gold From Electronics:

Be Careful When Picking Hazardous Chemicals

One of the most important aspects to consider when extracting gold from e-waste is safety. This begins with developing a plan for storing and using hazardous chemicals during extraction, but it also includes understanding how these chemicals could affect you or your community if they were spilled or mishandled.

For example, some common methods use cyanide that can be fatal if concentrated enough in the environment.

Other steps like testing air quality before beginning work will help reduce any potential risks while working on this project around children and pets.

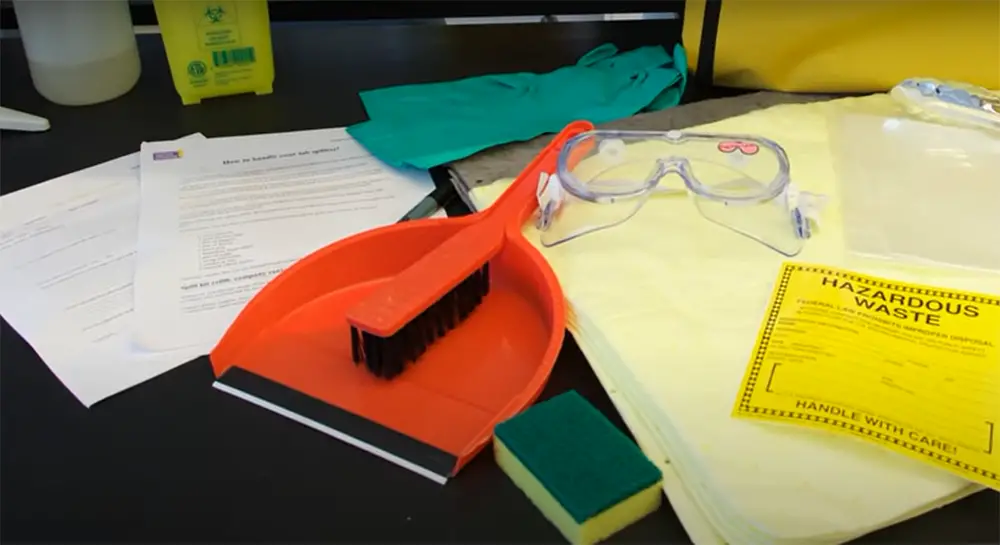

Prepare Materials and Safety Equipment

Once you have assessed the hazards associated with the chemicals and equipment you will be using, it is important to gather all of the necessary supplies and safety gear. This includes items like a face mask, gloves, goggles, and lab coat to protect your skin and clothes from any harmful substances. You should also have an emergency plan in place in case of accidents or spills.

Follow Safe Handling Procedures

In addition to wearing personal protective equipment (PPE), other safe handling procedures should be followed when working with hazardous chemicals. These include avoiding contact with eyes and skin, never eating or drinking while working, washing hands thoroughly after use, and properly storing chemicals away from children and pets.

If you are inexperienced in working with chemicals, you should consult a professional to learn more about safe handling procedures for the particular substances that you will be using [1].

Prepare Electronics for Gold Extraction

After you have carried out the necessary safety measures, it is time to start extracting gold from your e-waste. First, disassemble all of your electronics into individual pieces by following manufacturer instructions (if possible), and sorting them into plastic, metal, and glass waste bins.

Be sure to separate any hazardous materials like batteries or capacitors before disposing of them in a regular trash receptacle because they may explode if incinerated with other items.

Clean Off PCBs

The next step is to clean off any residual plastic, metal, or glass from the PCBs. You can do this by using a solvent like acetone that will dissolve most non-metallic substances. Just be sure to avoid getting the acetone on any of the electronic components themselves or on your skin because it is highly flammable and toxic.

Create The Etching Solution

Now it is time to create the etching solution that will be used to remove the gold from the PCBs. This can be done by dissolving a small amount of cyanide in water (be sure to use protective gear when handling cyanide). The concentration of cyanide in the solution will determine how much gold is removed from the PCBs. A higher concentration will result in more gold being extracted, but it also increases the risk of accidents and health hazards.

It is important to remember that any leftover cyanide solution must be disposed of properly because it is very dangerous if ingested or inhaled.

Extract the Gold Foils

With the etching solution prepared, it is time to start extracting the gold foils from the PCBs.

First, submerge the PCBs in the solution and let them soak for a few minutes. Then use a metal brush or scraper to remove the gold foil from the boards.

Be sure to wear gloves and goggles while doing this because cyanide is poisonous if ingested or comes into contact with your eyes.

Filter Out Gold Foils

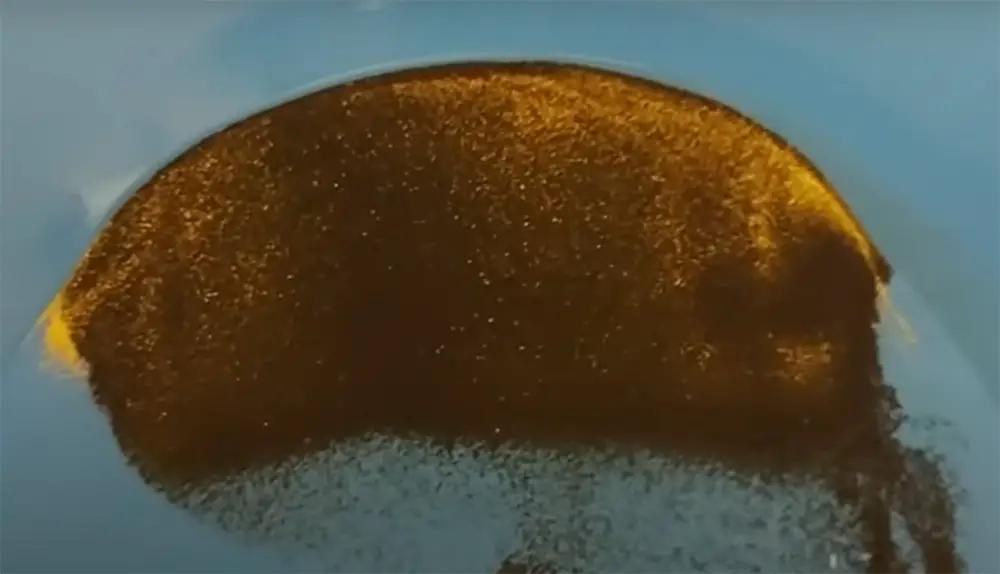

After you have removed all of the gold foil from the PCBs, it is time to filter out the foils from the etching solution. You can do this by pouring the solution into a glass or plastic container and allowing the gold foils to settle at the bottom. Once they have settled, use a spoon or other utensil to remove them from the solution and dry them off. Or you may use a coffee filter for this purpose.

Remove the Gold Foils Sticking to the Coffee Filter

Now you will need to remove the gold foils that are sticking to the coffee filter. To do this, simply place the coffee filter in a glass or plastic container and pour some acetone over it. The acetone will dissolve the adhesive that is holding the gold foil to the filter, and they will fall off into the container. Be sure to wear gloves and goggles while doing this because acetone is poisonous if ingested or comes into contact with your eyes.

Once all of the gold foils have been removed from the coffee filter, dry it off and dispose of it in a regular trash receptacle.

Dispose of Hazardous Wastes Properly

If you are not sure where to take your e-waste for disposal, call up any nearby electronic components stores or repair shops and ask if they provide this service. They will most likely be able to direct you to someone who can help you properly recycle your waste.

How to Remove Gold from Circuit Boards:

Use Nitric Acid

If you have a circuit board with gold plating, you can remove the gold using nitric acid. The acid will dissolve the metal and leave the non-metallic components of the circuit board intact. Be sure to wear goggles and gloves when working with nitric acid, as it can cause chemical burns.

Place the circuit board in a beaker or jar and cover it with concentrated nitric acid. Let it sit for about 15 minutes, then stir gently with a glass rod. The gold should start to dissolve and form a yellow solution at the bottom of the container. When all of the gold has dissolved, pour off the solution into another container. Rinse the circuit board thoroughly with water to remove any traces of acid [2].

Use Fire Assay

If you have a large amount of gold-containing scrap to deal with, fire assay is the best way to process it. This method involves melting down your material in an open crucible and pouring it into ingot molds for cooling. You can make small ingots using clay or sand molds, but if you are working with larger quantities, custom steel molds should be used instead. The resulting bars will contain around 90% pure gold by weight.

Use a Gold Leaching Process

Another option is to use leaching processes such as cyanidation or mercury amalgamation. These methods take advantage of the fact that most non-precious metals dissolve fairly easily in solutions containing compounds like sodium cyanide (NaCN) or mercury [3].

Comparison of Different Methods for Extracting Gold from Electronics Without Chemicals

With the rise of electronic waste, there is an increasing need to extract valuable materials such as gold from electronic devices. However, traditional methods involving chemicals can be hazardous to both humans and the environment. In this table, we compare different methods for extracting gold from electronics without the use of chemicals.

| Method | Gold Recovery Rate (%) | Cost ($) | Time Required (hours) |

|---|---|---|---|

| Gravity Separation | ~90% | Low | 1-2 |

| Mechanical Agitation | ~80% | Low-Medium | 4-6 |

| Electrostatic Separation | ~70% | Medium | 2-3 |

| Plasma Technology | ~95% | High | 1-2 |

| Bioleaching | ~80% | Medium | 2-3 |

The table compares different methods for extracting gold from electronics without the use of chemicals. The methods include gravity separation, mechanical agitation, electrostatic separation, plasma technology, and bioleaching. The table presents the gold recovery rate, cost, and time required for each method. Gravity separation and plasma technology are the most efficient methods with recovery rates of approximately 90% and 95% respectively. However, plasma technology is more expensive compared to other methods. Mechanical agitation and bioleaching are low-cost methods but require a longer time for gold recovery. Electrostatic separation is a medium-cost method with a recovery rate of approximately 70%. Overall, the choice of method will depend on the specific requirements of the user, including efficiency, cost, and time.

Check more articles to upgrade your knowledge in electronics:

- How to Build a Prototype Electronic Circuit?

- How is a Microprocessor Different from an Integrated Circuit?

- How to Solder a Radiator?

FAQ

1. How do you extract gold from electronics at home?

To extract gold from electronics at home, get yourself a device that can separate the pure gold wire. The easiest way to do it is by using a centrifuge machine. It separates all types of materials via different densities and weights at high speed with a low damage rate on each material.

You need firstly to dismantle your old devices into pieces as small as possible before you feed them into the machine if they are too big while processing so that they will be separated faster and more efficiently after being fed through the machine fixed blades or hammers (which help break down electronic parts without causing any damages).

Then throw these broken down components together with some bowl full of water inside this machine for about 15-20 minutes until there’s no more debris left, and you’ll end up with pure gold [4].

2. Is recovering gold from electronics worth it?

Many electronics have gold in them. This is especially true if the device has any sort of touch screen or a camera on it, but this does not mean that every piece of electronic equipment will contain gold and therefore be worth recovering.

In order to find out exactly how much money can be made by selling your old electronics for their precious metals content, you should look up the current market value of scrap metal prices before deciding whether or not such an undertaking would make sense for you.

The average price per ounce at which most common household items like computer parts and cell phones are currently fetching on e-scrap markets range from $0.50 all the way down to as low as just one cent.

3. Will hydrochloric acid and hydrogen peroxide dissolve gold?

In fact, under highly acidic conditions, gold dissolves in the presence of both a strong oxidant and a halide ion. Furthermore, according to the chemical process, a hot solution of hydrochloric acid combined with hydrogen peroxide also dissolves gold [5].

4. Will vinegar dissolve gold?

Even a fairly dilute solution of white vinegar in water can dissolve gold, but you will not get the same kind of results as with hydrochloric acid. White distilled vinegar is weaker than its chemical cousin and it only works at even lower pH values (around 0).

The vinegar’s acid needs a few minutes to react with gold and other materials. Just to be sure, leave the vinegar on your gold piece for at least 15 minutes. Check the color of your gold for changes such as black or green to determine if it is genuine [6].

As you might have already suspected, both acids are strong so if any skin or sensitive parts like eyes come into contact with them wash immediately with plenty of water.

Gold dissolves better in hot sulfuric and nitric acid than in cold solutions. Molten chloraurate also dissolves gold well, producing chlorine gas which may be harmful to your health. So do try this method outdoors for safety reasons!

5. What electronics contain the most gold?

The most precious metal by weight is CPU (processors) followed by Memory (RAM) & Circuit Board Fingers/Connectors/Pins, then Motherboards), then cables/wires, with hard drives & whole computers being last [7].

6. How much gold is in a motherboard?

On a motherboard, there are about 20 gold connectors of various sizes. These range from .14-.40 mm in width and have a total weight of around .35 grams.

There are also smaller amounts of gold on the other parts of the motherboard such as the chips and capacitors. A single chip can contain anywhere from a few hundredths to more than one milligram of gold while capacitors usually have traces of the precious metal totaling less than 100 micrograms per device.

A typical desktop computer contains around half a gram (500-700 mg) of gold, most of which is found in CPUs, memory modules, and connectors on the circuit board. Therefore, if you’re lucky enough to own an old desktop, you might be able to extract as much as $35 worth of the precious metal. Laptops are not typically as rich in gold as desktops, containing only around 150-200 mg per device [8].

7. How much gold is in a cell phone?

Each cell phone contains 0.034 grams of gold, according to the US Geological Survey. That’s the equivalent of roughly 0.001 troy ounces, which is worth about $1.82 today [9].

8. Is there gold in TV remotes?

Small quantities of valuable gold may be profitably recycled by a precious metals refinery like Specialty Metals Smelters and Refiners, which are known as remotes. And the more of them you have, the more money you can make [10].

9. What karat gold is in electronics?

The purity of gold in electronic components is usually 24 or 22 karat. Karatage is a method to assess the purity of gold, which starts at 24 and has 99.9 percent purity. The purest material, but it’s also less dense and isn’t used in most jewelry. It’s utilized in medical devices as well as consumer electronics [11].

10. How do you get gold out of computers?

To extract gold from electronics, you will need the following materials:

- A strong acid – like hydrochloric or nitric;

- A catalyst – a chemical that causes the reaction to happen very quickly. Electricity is an additional element that doesn’t play any role in catalyzing reactions but it’s needed for heating purposes;

- Hot water (hotter than 122F);

- To collect your extracted gold, you can either use a metal bowl or jewelry-grade crucible and mold;

- You’ll also need safety equipment such as goggles and gloves because acids are harmful when they come into contact with human skin and eyes;

All that remains is to start the process and see what happens, so let’s get started:

- First of all, you need to extract a component from your device in order for it to dissolve into acids – this means digging out chips or circuit boards containing gold connectors;

- The next step is heating up water (122F) with nitric acid – 25-35% concentration should do nicely. Add the catalyst silver oxide which lets off hydrogen gas as well as activating other chemicals involved in the reaction (nitrates). The gases produced are highly flammable so be careful about sparks near any open flames during this part of the procedure;

- Add water again and pour everything over components extracted earlier;

- Now you just need to wait a while (about half an hour)! The circuit boards are saturated with gold, which can be easily collected by pouring the liquid into another container. It’s best not to leave any time for evaporation – as it could lead to some losses of precious metals from your solution;

References:

- https://www.instructables.com/How-To-Extract-Gold-From-Electronics

- https://www.wikihow.com/Remove-Gold-from-Circuit-Boards

- https://www.wired.co.uk/article/extract-gold-from-electronics

- https://19january2017snapshot.epa.gov/international-cooperation/artisanal-and-small-scale-gold-mining-without-mercury_.html

- https://www.redorbit.com/news/science/211943/a_method_for_leaching_or_dissolving_gold_from_ores_or

- https://www.wikihow.com/Test-Gold-with-Vinegar

- https://www.conceptmanagement.co.uk/knowledge/materials/precious-metal

- http://therefiningcompany.com/How-Much-Gold-Is-In-A-PC.aspx

- https://money.cnn.com/2011/10/13/technology/iphone_trade_in/index.htm

- https://www.specialtymetals.com/blog/2014/11/19/are-you-sitting-on-precious-metals-you-dont-even-know-about-its-remotely-possible

- https://www.qml.us/how-do-i-improve-my-gold-scrap-refining-returns

As a child I was surprised to learn that many electronics contain gold. I had always thought of gold as a valuable metal, but I never realized that it was used in so many different ways. Everything from cell phones to computers to medical devices contain trace amounts of gold.

I remember when I first learned about this, I was looking through an old cell phone that I had. I started to notice that the connectors on the back of the phone were all a very bright gold color. When I looked closer, I could see that there was actual gold metal in them!

Motherboards are especially stacked with gold. In fact, a single motherboard can contain upwards of 3 grams of the stuff. Computers also use gold in their central processing units (CPUs) and graphics processing units (GPUs).