Thermocouples are a widely used tool in temperature-sensing and measurement, found as components of industrial processes as well as commercial applications. But what is a thermocouple exactly? What makes it so useful, and how does it function to provide such reliable results? In this blog post, we’ll take an in-depth look at the science behind thermocouples – including how they’re constructed and their various uses across multiple industries. Read on to learn all you need to know about these incredible pieces of engineering!

What Is A Thermocouple?

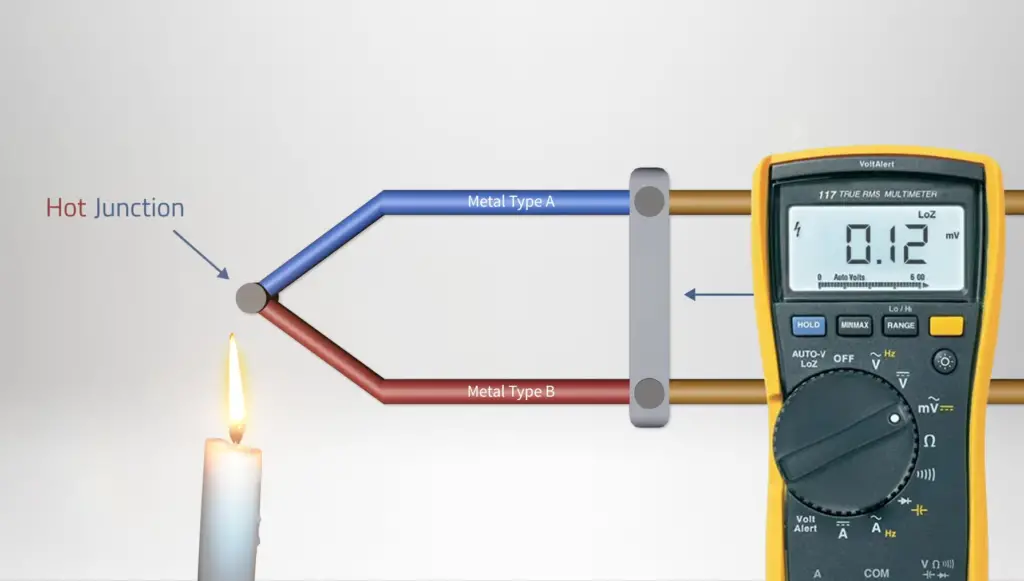

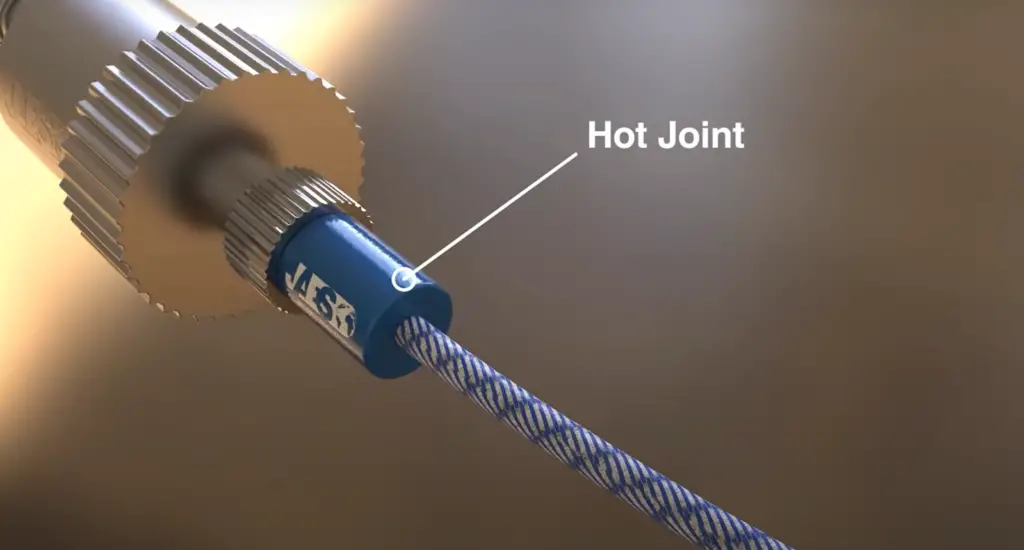

For accurate temperature measurements, a thermocouple is the perfect choice as it can detect even minuscule variations in temperatures between two points of contact. Connected at one end, two distinct metals are joined together on the other side with an electrical circuit. The two junctions create a small voltage when there is a change in temperature between them. This voltage can be read by instruments and converted into temperatures for easy interpretation.

How Does A Thermocouple Work?

By capitalizing on the Seebeck effect, a thermocouple is able to function. By joining two distinct metals, the Seebeck effect induces a voltage-creating an entirely new source of energy. This voltage can also be employed to accurately gauge temperature fluctuations.

Different types of thermocouples are designed for different temperature ranges and accuracy levels. Generally speaking, the higher quality and more accurate the thermocouple, the more expensive it will be. However, many applications do not require an incredibly high level of precision and accuracy – in these instances, a basic thermocouple would suffice.

When a thermocouple is connected to a measuring instrument (such as a thermometer or data logger) it creates a complete circuit which allows the instrument to measure the voltage produced by the thermocouple. The voltage created is directly proportional to the temperature difference between the two junctions of the thermocouple. This allows temperatures to be measured accurately and reliably over a wide range of temperatures.

In order for a thermocouple to function properly, it must have a reference junction (usually at 0°C or 32°F) that is insulated from any external heat source. If this reference junction is exposed to an external heat source, it can cause inaccurate readings in the resulting measurements.

They provide quick response times and accurate readings within their given temperature range and can be used in a variety of environments.

Thanks to their robustness and versatility, thermocouples are one of the most popular temperature measurement devices available today. They have become indispensable tools for many industries ranging from automotive to aerospace and even medical. No matter what kind of temperature monitoring you require, chances are there is a thermocouple suitable for your application! [1]

What Is A Thermocouple Used For?

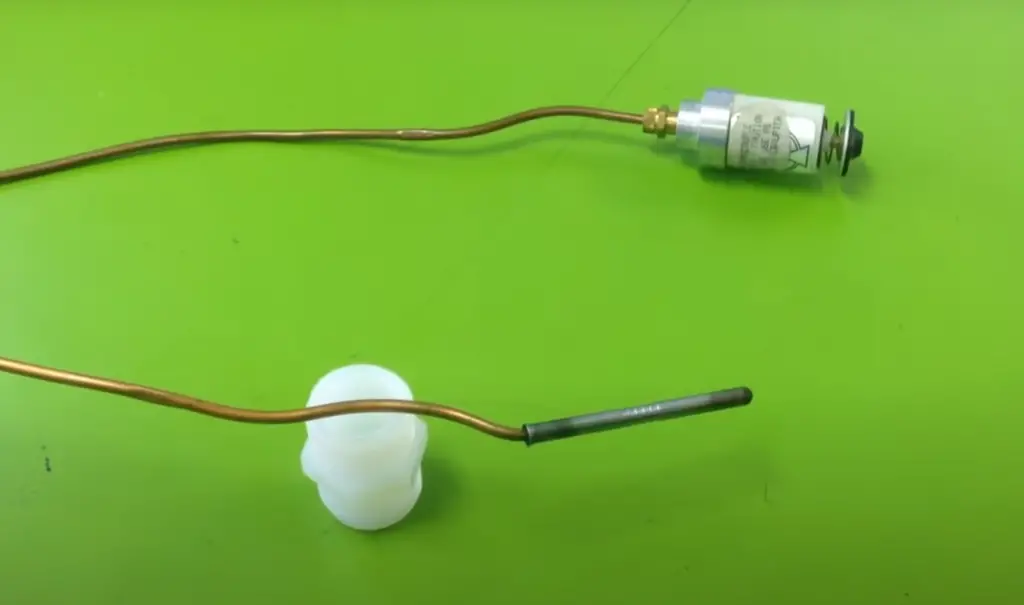

It is particularly useful for measuring temperatures of surfaces and objects, which can range from very hot to very cold. Thermocouples are often used to measure and monitor the temperature of industrial processes, such as in ovens, furnaces, water heaters, boilers and air conditioners. They are also commonly used in power plants to measure and monitor turbine exhaust-gas temperatures.

In addition to being a reliable source of temperature readings, they are relatively inexpensive and easy to install. On top of that, thermocouples provide accurate readings over long distances by using amplifiers or transmitters. This makes them an ideal choice for monitoring temperatures in remote locations.

Thermocouples are also used in many consumer products, such as refrigerators and grills. They can be used to quickly measure the temperature of a surface or object, allowing manufacturers to ensure that their products are functioning correctly and meeting safety standards. Furthermore, thermocouples can be connected to alarms or controllers for automated temperature control in applications like greenhouses, incubators and other critical environments.

Thermocouples have become an essential tool in multiple industries due to their accuracy, reliability and cost-effectiveness. With its versatility, it is no surprise why they are so widely used by engineers around the world. [2]

What Are The Different Types Of Thermocouples?

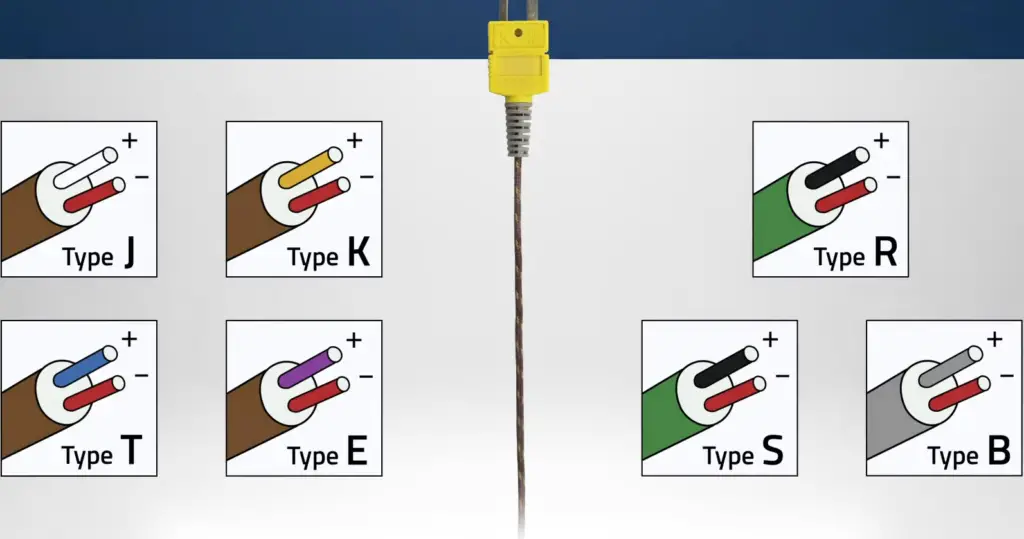

Thermocouples come in a variety of types and materials, each suited for specific situations. Commonly used thermocouple types are Type K (Chromel/Alumel), Type J (Iron/Constantan), Type T (Copper/Constantan), Type E (Chromel/Constantan) and Type N (Nicrosil/Nisil). There are also specialty thermocouples such as Types R and S, which operate at higher temperatures.

Each type contains two dissimilar metal wires that create an electrical current when subjected to temperature change. The voltage generated is proportional to the temperature difference between the hot junction and cold junction of the thermocouple. It is important to choose the right thermocouple type for the application in order to get accurate readings.

The most commonly used thermocouples are Type K and Type J, as they offer good stability in a wide range of temperatures. They are also resistant to oxidation and corrosion. Type T thermocouples have a narrower temperature range than Types K or J but can be used in applications where higher accuracy is required such as laboratory measurements. Type E thermocouples offer increased accuracy over Types K and J, while Type N has a large temperature operating range with improved accuracy over other types.

For extreme-temperature applications, specialty thermocouples such as Types R and S should be used. These thermocouples are constructed with a noble metal such as platinum or tungsten, which can withstand higher temperatures. Additionally, they provide greater accuracy and stability than other thermocouple types.

To ensure accurate readings, it is important to use high-quality thermocouples that are compatible with the application in question. Using the wrong type of thermocouple or one that is not suited for extreme temperatures can lead to erroneous results, so it is important to do research before buying any thermocouples. Additionally, thermocouples should be handled carefully and stored properly when not in use to prevent damage and contamination.

Experimentation and analysis may be necessary in order to determine the best type of thermocouple for an application. With the right thermocouple, temperature measurements can be taken accurately and reliably in a variety of applications.

What Happens If A Thermocouple Fails?

When a thermocouple fails, the measurement process is compromised and inaccurate readings can occur. This can lead to incorrect decisions being made regarding equipment operations, resulting in costly downtime or other problems. In cases where safety is involved, such as power plant monitoring, an incorrectly reading thermocouple can put personnel and equipment at risk. Therefore, it is important that any failed thermocouples are identified and replaced promptly.

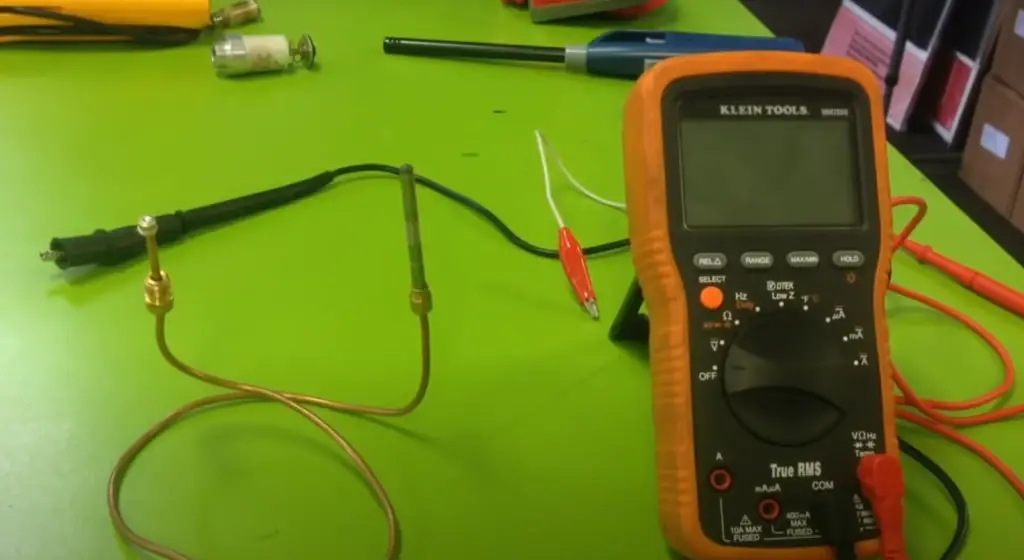

There are several common signs of failure including low voltage output, inconsistent readings, or complete loss of signal. To prevent failures from occurring in the first place, it is important to select a quality sensor for the application and to ensure that it is regularly inspected for wear and tear. Additionally, proper installation will help to ensure long-term operation and accuracy of the thermocouple.

In conclusion, thermocouples can be a very effective way to measure temperature accurately if used correctly. However, it is important to regularly inspect any installed units as well as promptly replace any that have failed in order to maintain accurate readings and avoid potential safety hazards. Doing so will help ensure that the measurements are reliable and provide valuable data for decision making. [3]

What Problems Can You Have With Thermocouples?

Thermocouples are incredibly versatile, reliable, and accurate instruments. However, they’re not perfect, and there are a few problems that can occur with thermocouples that you should be aware of. First off, thermocouple accuracy can decrease over time due to age-related degradation or contamination from dust particles entering the tip of the device. This can cause readings to become inconsistent or inaccurate; however, the problem can generally be solved by replacing the thermocouple or cleaning its tip.

Additionally, electromotive force (EMF) interference from nearby electrical sources can also affect thermocouple accuracy, so it’s important to keep them away from any strong electromagnetic fields.

Finally, temperature differences between two thermocouples connected in series can cause errors, so it’s important to ensure that they are at the same temperature before taking measurements.

Overall, thermocouples are incredibly reliable instruments; however, if you’re aware of these potential issues and take appropriate precautions, you can be sure to get accurate results every time.

What Are The Advantages Of Using Thermocouples?

Thermocouples are versatile, precise and economical temperature sensors.

Thermocouples offer several advantages over other types of temperature sensors such as RTDs.

For example:

- Easy installation: Thermocouples are inexpensive and easy to install compared to RTDs. No special tools or connection hardware is required for installation.

- Fast response time: Thermocouple response times can be as little as one second, which allows for faster reaction time in many applications.

- Accuracy and precision: When calibrated correctly, thermocouples provide very accurate and precise measurements.

- Durability: Thermocouples are highly durable, making them suitable for harsh environments.

- Wide temperature range: They can measure temperatures from -270°C (-454°F) up to 2315°C (4199°F).

Thermocouples are widely used in many industries such as pharmaceuticals, food processing, petrochemical, and power generation due to their accuracy and durability over a wide temperature range. Additionally, they require minimal maintenance compared to other types of temperature sensors. This makes thermocouples a reliable and cost effective choice for many applications. [4]

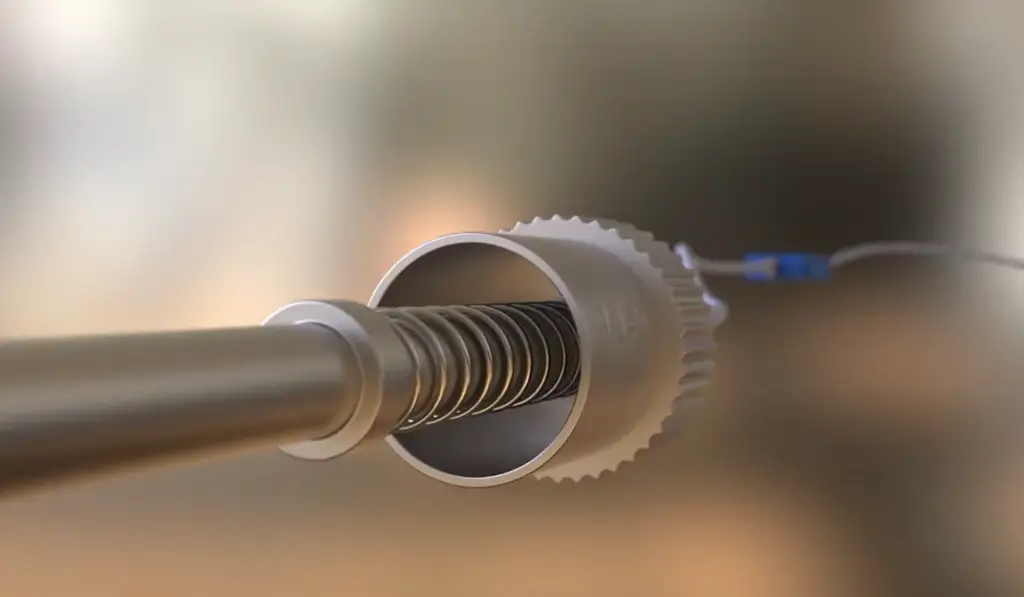

How Do You Set Up A Thermocouple?

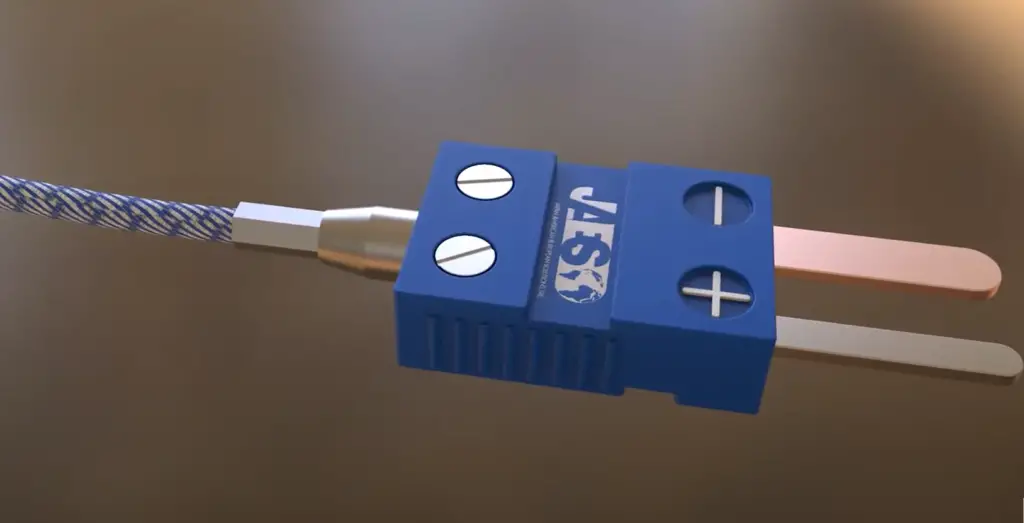

Setting up a thermocouple is relatively simple, depending on its type. Generally, the setup process involves connecting both ends of the thermocouple to a measurement instrument like an electrical meter or data logger. To accurately measure temperature, each end of the thermocouple must be connected to the correct side of the instrument. For example, if using a Type K thermocouple (the most common type), one end should connect to the “K” terminal while the other should connect to the “COM” terminal.

Once connected properly and wired correctly, your thermocouple will be ready for use. If you are monitoring temperatures over time with a digital data logger device, it’s important that all connections are tight and secure prior to recording your data. This will help ensure that the temperature readings are accurate and do not drop off or experience any electrical interference. Additionally, depending on the environment in which your thermocouple is situated, you may need to calibrate it regularly to account for environmental changes like humidity or pressure.

Overall, setting up a thermocouple is relatively straightforward, but it is important to pay close attention to each step of the process in order to get accurate results. With the right setup processes in place and regular maintenance checks, you can confidently monitor temperatures with your thermocouple for years to come!

What Are The Materials Used For Thermocouples?

Thermocouples are typically composed of two dissimilar materials, often metal alloys. Common thermocouple types include Iron-Constantan (Type J), Copper-Constantan (Type T), and Chromel-Alumel (Type K). The junction between the two dissimilar metals creates an electrical potential that varies with temperature; when no current is flowing through the junction, it is at its equilibrium state and will measure a voltage corresponding to the ambient temperature.

As the temperature increases or decreases, so does the measured voltage. This variation in voltage can then be interpreted by an electronic circuit to display a temperature reading on a digital display. Additionally, these varying voltages can also be used to control other devices such as fans, valves and other components in an automation system.

The selection of the two dissimilar metals used in a thermocouple is very important because they need to be chosen based on their thermoelectric properties. The metals should have different Seebeck coefficients which determines how temperature changes affect the measured voltage; this information can be easily found by consulting the manufacturer’s product datasheet. [5]

How Many Wires Does A Thermocouple Have?

A thermocouple typically has two wires. One wire is made from a material known as the positive leg and the other from a material known as the negative leg. The materials of these two wires have different temperatures when subjected to a given temperature, creating an electric potential between them. This difference in electric potential enables the measurement of temperature by a signal that can be read by electronic instruments.

In other cases, thermocouples are used with three or four wires. While each set of two wires comprises one thermocouple junction, additional junctions can provide more accurate readings in certain applications. These extra-long leads also allow for compensation for errors in measuring temperature due to varying resistance along the wire length.

How to Choose A Thermocouple?

Range and Accuracy

Thermocouples come in a variety of temperature ranges and accuracies. It is important to choose the right thermocouple for your application, as it can measure temperatures as low as –270°C or as high as 1400°C. The accuracy varies depending on the type of thermocouple being used.

Environment

Different environments require different types of thermocouples. If a thermocouple is exposed to harsh conditions such as corrosion, radiation, pressure shock or vibration, then you must select an appropriate material that can withstand these forces. Additionally, if the environment involves hazardous materials or contaminants, special shielding should be considered when selecting a thermocouple.

Response Time

The response time of a thermocouple is determined by the overall mass and thermal capacity of the element. The larger the diameter, and therefore greater mass, of the junction will increase response time, as it takes more time for heat to travel through a thicker wire. Mass also affects accuracy and repeatability; if you need an element that can respond quickly to temperature changes, then choose a smaller-diameter thermocouple.

Price

Price is an important factor when selecting a thermocouple as there are many different types available on the market with varying prices depending on type, environment, range and accuracy. It is important to consider the usage application before making your decision in order to select a thermocouple with all the necessary features at an affordable price.

Styles of Thermocouples

When selecting a thermocouple, it is important to consider the style that best fits your application. Some of the different styles include head and stem, miniature and flex-type. The style chosen will depend on size constraints, ease of installation and protection against possible contamination.

It is important to consider all these factors before making a decision when choosing a thermocouple for an application. [6]

FAQ

What is a thermocouple and how does it work?

A thermocouple is a device used to measure temperature by taking advantage of the Seebeck effect. It consists of two different metals, or alloys, that are joined together at one end. When this junction experiences a change in temperature, it produces an electrical voltage as a result of the Seebeck effect. This voltage can then be measured and used to determine the temperature of the object being measured. The two metals chosen for use in thermocouples must have different Seebeck coefficients so that they will respond differently to changes in temperature, allowing accurate measurements to be taken. Thermocouples are often used in industrial settings due to their accuracy and reliability. They can also be found in consumer products such as ovens and other appliances.

What are the different types of thermocouples?

Thermocouples come in a variety of shapes, sizes and materials. The most common type is the K-type thermocouple, which consists of two pieces of Chromel and Alumel (Nickel-chromium and nickel-aluminum alloys). Other types include J-type (Iron and Constantan), T-type (Copper and Constantan) and E-type (Chromel and Constantan). Each type has different characteristics that make it suitable for different environments or applications. For example, the K-type thermocouple is often used in high temperature measurements due to its accuracy at higher temperatures.

What are the advantages of using a thermocouple?

Thermocouples have several advantages over other temperature measurement devices. They can measure temperatures over a wide range, from -200°C to +1000°C, and are relatively inexpensive compared to other types of sensors. They are also highly accurate and reliable, with minimal drift over time or exposure to extreme environments. Additionally, thermocouples do not require power for operation, making them ideal for remote monitoring applications where power is not easily accessible. Finally, they are easy to install since no additional wiring is required; simply connect the two alloys at one end and the voltage generated by the Seebeck effect will indicate the temperature.

What are some common applications of thermocouples?

Thermocouples are used in a wide variety of applications, from industrial processes to consumer products. In the automotive industry, they are often used to measure engine temperature or exhaust gas temperatures. They can also be found in medical equipment, such as infrared thermometers and MRI scanners, as well as ovens and other household appliances. Additionally, they can be used for laboratory experiments that require precise temperature measurements. Finally, thermocouples are also used in process control systems where they provide accurate readings of temperatures within pipes and tanks.

Is a thermocouple AC or DC?

The answer depends on the type of thermocouple. Generally speaking, thermocouples are designed to measure temperature with AC signals, while some thermocouples use DC signals. For example, Type J and Type K thermocouples use an alternating current signal to measure temperatures in the range of -210°C to 1,260°C. On the other hand, Type T and Type E thermocouples operate using a direct current signal in order to measure temperatures up to 250°C and 400°C respectively.

What temperature is thermocouple?

A thermocouple is a device used to measure temperature by sensing changes in electrical potential or voltage. The standard range of temperatures it can measure is usually -200°C to +1300°C, although some types of thermocouples have an even wider range. It works on the principle that when two different metals are joined together at one end and heated at the other end, a small voltage develops between the two points. This voltage is proportional to the temperature difference between the two ends. Thermocouples are widely used for industrial applications as they provide accurate readings over a wide range of temperatures and are very resilient to harsh environments. Additionally, they are inexpensive and easy to install compared with other temperature sensors such as RTDs or thermistors.

Can thermocouple measure voltage?

No, a thermocouple does not measure voltage directly. It measures temperature based on the electrical potential generated when two different metals are joined together and heated. This voltage is proportional to the temperature difference between the two ends of the thermocouple. For this reason, it cannot be used to accurately measure voltage or other electrical signals. In some cases, however, it can be used to indirectly detect an increase or decrease in voltage by measuring changes in temperature caused by fluctuations in electric current. Additionally, some varieties of thermocouples are available that feature built-in amplifiers which can directly measure very small voltages with high accuracy.

Is thermocouple positive or negative?

The answer to this question can depend on the type of thermocouple being used. Generally, the negative terminal is referred to as the cold junction and the positive terminal is referred to as the hot junction. In some types of thermocouples, such as Type J or K, the negative terminal is at a higher temperature than the positive terminal. In other types of thermocouples, like Type E or R/S, it may be reversed with the positive terminal at a higher temperature than the negative one. It’s important to consult your thermocouple manufacturer’s manual for specific information about your type of thermocouple.

Useful Video: How does a Thermocouple work? – Seebeck effect – Various types of thermocouples

Conclusion

A thermocouple is a device that accurately measures temperature by converting thermal energy into electrical signals. It consists of two dissimilar metals joined together to form a junction at one end, and its other end is connected to an amplifier and display instrument. The electric current produced by the thermocouple depends on the difference in temperature between the two metals, making it useful in monitoring and controlling temperatures in various applications such as furnaces, kilns, ovens and medical equipment. It´s simple design, high accuracy, wide range of operating temperatures, low cost, and robustness make it a popular choice for many industrial purposes.

In conclusion, the thermocouple has proven to be an invaluable tool for measuring temperature accurately. It has widespread use in industry and is present in many everyday appliances. Its versatility and ease of use make it the ideal choice for a variety of applications and its accuracy can be relied upon with confidence. With advancements in technology, new thermocouple designs are constantly being developed to increase accuracy and reduce cost, making this device an even more useful tool for scientists, engineers, medical professionals and technicians alike.

References

- https://www.omega.co.uk/prodinfo/thermocouples.html

- https://www.processparameters.co.uk/what-is-a-thermocouple/

- https://www.iqsdirectory.com/articles/thermocouple.html

- https://realpars.com/thermocouple/

- https://www.pyrosales.com.au/blog/thermocouple-information/what-is-a-thermocouple/

- https://peaksensors.co.uk/blog/what-is-thermocouple-how-does-it-work/

Leave a Reply