A soldering iron is a hand tool that uses heat to join metal pieces. It’s an essential tool for any DIY enthusiast or professional, and there are many different types of soldering irons available on the market. In this article, we will discuss the different types of soldering irons available and their various applications. We’ll also provide some tips on how to use a soldering iron safely and effectively. So whether you’re a beginner just starting out in the world of DIY or a seasoned pro, read on for everything you need to know about soldering irons!

What is Soldering

Soldering is a process in which two or more pieces of metal are joined together by melting and flowing a filler metal (solder) into the joint. The filler metal has a lower melting point than the base metals being joined, so it can be melted without damaging them. Soldering is widely used in electronics because it can create very strong and reliable electrical connections.

There are two main types of soldering: hard soldering and soft soldering. Hard soldering is used to join metals that have a high melting point, such as steel or copper. Soft soldering is used to join metals with a low melting point, such as aluminum or brass, because of that it is mainly utilized in electronics.

While soldering creates a much weaker bond than welding, it has the advantage of being able to join dissimilar metals and being much easier to do. It also doesn’t require any special equipment or training, making it a popular choice for many DIY projects. [1]

What is a Soldering Iron

A soldering iron is a hand tool used in welding and electronics work. It consists of a metal tip that gets heated to high temperatures, which is then used to melt solder so it can flow into the joint between two pieces of metal.

Solder is a metal alloy that has a lower melting point than the metals being joined, so it can be used to create a bond between them.

There are two types if solders: lead-based and lead-free. Lead-based solder has a lower melting point than lead-free solder, so it is easier to use. However, lead is a toxic metal that can be harmful if inhaled or ingested, so lead-free solder is safer to use.

There are also a few things to keep in mind when soldering. First, it is important to use the correct type of solder. Second, the surface of the metal must be clean and free of any dirt or debris. Third, the soldering iron must be the correct temperature; too hot and the metal will melt, too cold and the solder will not adhere properly. Finally, it is important to use the correct flux; this will help to prevent the metal from oxidizing and will make the solder flow more smoothly. [1], [2]

Applications of Soldering Iron

While soldering irons are most commonly used in electronics work, they have many other applications as well. Let’s discuss them.

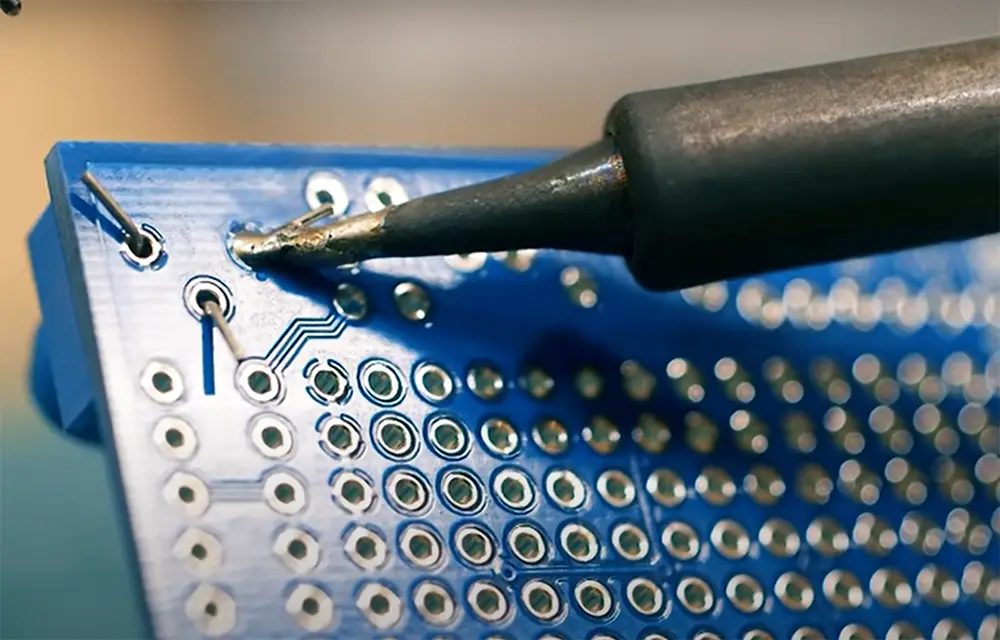

Soldering for circuit boards

The most common use for a soldering iron is probably circuit board soldering. This involves attaching electronic components to a printed circuit board (PCB) as well as connecting wiring between different points on the board. Although it is possible to do this by hand, most people use a soldering iron in conjunction with a soldering station.

A good tip for circuit board soldering is to use a higher wattage iron for larger components and a lower wattage iron for smaller components. This is because the heat needs to be transferred evenly across the component in order to avoid damaging it. Also, make sure that the tip of the iron is clean before each use as this will help to prevent any defects in your work. [3], [4],[5]

Jewelry making

One of the most popular applications for soldering irons is in artisan work. Many people use them to create custom designs and repair broken pieces. When soldering jewelry, it’s important to use a low-melting point solder so that you don’t damage the piece. You should also use a small amount of flux to prevent the metals from oxidizing.

You can use it to attach findings to pieces of metal or wire, solder jump rings closed, and much more. If you’re new to jewelry making, practice soldering on some scrap pieces of metal before moving on to your good jewelry. That way, you can get a feel for how the iron works without ruining any of your precious creations.repairing broken chains or other types of jewelry is also a breeze with a soldering iron. [3], [4], [5]

Mosaics

Mosaics are a type of art that involves creating images with small pieces of colored glass or stone. Soldering irons are often used to attach the pieces to a backing.

The heat from the iron melts a thin layer of metal on the piece, which adheres it to the backing.

This method is especially useful for large mosaics or those with irregular shapes, as it allows for a lot of flexibility in placement. It also eliminates the need for grout, which can be difficult to work with and can stain easily. [3], [4], [5]

Soldering stained glass

A soldering iron can be used to solder together pieces of stained glass. This is a popular use for soldering irons because it allows for a very precise and strong bond to be created between the two pieces of glass without the use of adhesives or other materials that could potentially damage the glass. [3], [4], [5]

Soldering in the roofing industry

One such application is soldering in the roofing industry. Roofers use soldering irons to solder flashings. Flashings are the metal strips used to waterproof areas vulnerable to leaks, such as around chimneys, skylights, and vents.

The benefits of using a soldering iron for this purpose are that it’s quick, easy, and doesn’t require any special skills or training. All you need is a steady hand and some patience. Accuracy doesn’t matter much either, since you can always trim the excess metal away later. [3], [4], [5]

Soldering metal gutters

Similarly, soldering metal gutters is another application for soldering irons. Gutters are usually made of copper or aluminum, and they need to be sealed at the seams to prevent leaks.

As with roof flashings, lead-based solder is typically used for this purpose. The main difference is that gutters are much larger than flashings, so a higher wattage iron is usually required.

Soldering in auto-repair business

While welding is more widely used in auto-repair, there are many cases where soldering would be a more appropriate solution. When it comes to smothering the rough surfaces, for example, soldering is often the best way to go.

This is because solder is made of a softer metal than most metals used in auto-bodies, making it easier to work with and less likely to cause damage. Additionally, solder will not conduct electricity like some metals will, meaning that you won’t have to worry about any dangerous sparks or shorts.

If you’re not sure whether welding or soldering is the right choice for your auto-repair project, consult with a professional or look up some tutorials online before beginning.

Keep in mind that soldering can’t be used for every auto-repair project. For example, if you’re trying to fix a hole that’s too large, soldering won’t work and you’ll need to weld the area instead. [3], [4], [5]

Uses of soldering for electricians

Because soldering guarantees electrical continuity between two or more components, it’s an essential skill for electricians. Electricians often need to join electrical wiring together, whether that’s in new construction projects or maintenance and repairs.

Electricians often use soldering to splice together the ends of electrical wiring, which creates a permanent and electrically conductive connection between the two pieces of metal. This type of joint is called a solder joint. [3], [4], [5]

Uses of soldering for plumbers

Soldering also sees its use in plumbing. Pipes are soldered together to create a water-tight seal that will not leak. This is especially useful for copper pipes as it creates a stronger join than simply using a pipe wrench. Plumbers usually prefer using lead-free solder as it is less harmful.

Soldering can also be used to repair leaks in pipes. To do this, plumbers first need to find the leak. Once they have found the leak, they will put a piece of solder over it and then heat it up with the soldering iron. The heat from the iron will cause the solder to melt and seal the leak. [3], [4], [5]

Soldering vacuum tubes

Vacuum tubes are often used in high-power applications, such as power amplifiers and RF transmitters. They require a higher soldering temperature than other electronic components, and therefore a soldering iron with a temperature control is necessary. The tip of the soldering iron must be very clean when working with vacuum tubes, as any contamination can cause the tube to fail.

Soldering vacuum tubes can help to insulate and protect the electrical connection between two metal surfaces. This can be useful in a variety of different situations, such as when you need to connect two pieces of electronic equipment together, or when you need to make a repair to an electronic device. [3], [4], [5]

Various DIY projects

Soldering irons are incredibly useful for small household projects. We’ve already mentioned that if you need to fix a broken pipe or want to make some jewelry, a soldering iron will come in handy.

You can also use a soldering iron to create custom art pieces. By melting different metals together, you can create unique sculptures or even just solder two pieces of metal together.

If you’re into woodworking, a soldering iron can be used to burn designs into wood. This technique is called pyrography and it’s a great way to add personalization to your projects. [3]

FAQ

Can soldering iron be used for metal?

The short answer is yes, soldering iron can be used for metal. However, it is important to keep in mind that not all metals are created equal. Some metals are more difficult to solder than others, and some require special techniques or materials. In general, though, soldering iron can be used for most metal applications.

What can you not do with a soldering iron?

A soldering iron cannot be used to weld metal together. Welding requires much higher temperatures than what a soldering iron can produce. Additionally, welding metals together generally requires special equipment and techniques that a soldering iron cannot provide.

A soldering iron is also not well suited for cutting through metal. While it can potentially melt through thin metal if the tip is hot enough, it will not produce clean or precise cuts. For this reason, other tools like saws or plasma cutters are typically used for cutting metal.

Can you burn wood with a soldering iron?

Yes, you can burn wood with a soldering iron, but it is not the ideal tool for the job. A soldering iron is designed to heat up and melt metal so that it can be joined together. Wood is not a good conductor of heat, so it will take longer to heat up. Still, it is possible to do it if you’re careful.

Should I wear a mask when soldering?

While lead-free solders don’t give off as many fumes as lead-based solders, it’s still a good idea to wear a mask when soldering. The fumes from soldering can be harmful if inhaled, so it’s better to be safe than sorry.

Another reason to wear a mask is to protect your lungs from the smoke that is produced when the solder melts. The smoke can contain harmful chemicals that you don’t want to inhale.

Useful Video: Types And Uses For Soldering Irons

Conclusion

Soldering iron is a versatile tool that can be used for a variety of tasks, from simple repairs to intricate electronics projects. It’s main purpose is to join two pieces of metal together, but it can also be used for various purposes such as jewelry making, repairs, and even simple crafts. With a little practice, anyone can learn to use a soldering iron and reap the benefits of this handy tool. So whether you’re a beginner or an experienced electronics enthusiast, be sure to keep a soldering iron in your toolkit. You never know when you’ll need it!

This guide has outlined some of the most common uses for soldering iron. Hopefully, it has also given you some new ideas on how to use this tool. As always, be sure to read the manufacturer’s instructions carefully before using any soldering iron. And never leave a hot soldering iron unattended. With proper care and safety precautions, you can enjoy many hours of safe and successful soldering projects. Thanks for reading!

References:

- https://www.hunker.com/13414270/what-are-the-three-types-of-soldering

- https://www.eptac.com/blog/leaded-vs-lead-free-solder-which-is-better

- https://www.hunker.com/13414270/what-are-the-three-types-of-soldering

- https://www.chandlertool.com/blogs/news/10-different-uses-for-your-soldering-iron

- https://essenziale-hd.com/2018/11/26/5-home-uses-for-a-soldering-iron/

In my view, the explanation provides a clear understanding of soldering and its essential components. The differentiation between lead-based and lead-free solder, with a focus on safety, is particularly valuable. Emphasizing the importance of correct solder, surface preparation, temperature, and flux selection highlights the precision and care required in soldering applications.

In my view, the explanation provides a clear understanding of soldering and its essential components. The differentiation between lead-based and lead-free solder, with a focus on safety, is particularly valuable. Emphasizing the importance of correct solder, surface preparation, temperature, and flux selection highlights the precision and care required in soldering applications.

Leave a Reply