The KSGER T12 Soldering Station is a great choice for anyone looking to take their soldering game up a notch. It’s perfect for hobbyists, students, and pros alike with its intuitive design and straightforward setup. Plus, its top-of-the-line features make it one of the most advanced soldering stations on the market. In this review, we’ll cover the basics of the KSGER T12 Soldering Station, answer some frequently asked questions, and provide a few tips to help you get the most out of your station. So let’s dive in!

A brief introduction to KSGER T12 soldering

The KSGER T12 Soldering Station is a great choice for those looking to expand their soldering capabilities. It features an intuitive design with two separate temperature control knobs, one for the soldering iron and one for the hot air gun. The station comes with ceramic heating elements and digital PID technology that ensure accuracy and consistency, making it more than capable of tackling even the most intricate soldering projects. The station also features a sleep and hibernation mode that helps conserve electricity and extend its life. [1]

What is a KSGER T12 soldering station?

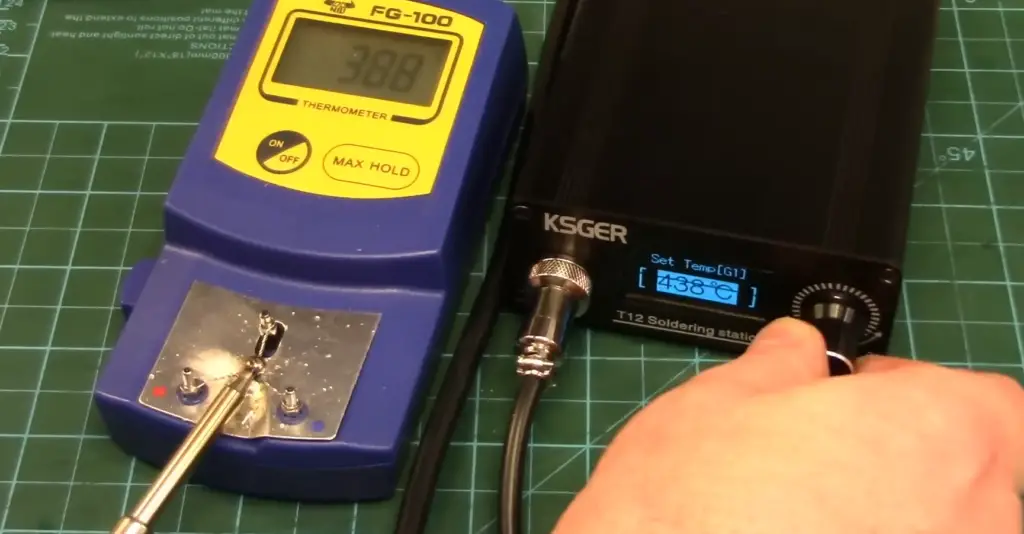

It has a large LCD screen that displays the current set temperature as well as wattage selection information. The station comes complete with a soldering iron, quality stand, and sponge. [1]

Is a Soldering Station Necessary?

Yes, a soldering station is essential for any electronics project. It provides you with the right tools and materials to create reliable connections between electronic components. The KSGER T12 soldering station is an excellent choice because it offers all the features you need in one convenient package. It comes with adjustable temperature control, a digital display, and various soldering tips that make it easy to solder a wide range of components. The safety features also make this soldering station the perfect choice for both experienced and novice solderers alike. [1]

Types of Soldering Stations

The KSGER T12 Soldering Station is a type of soldering station, which is an electronic tool used to heat small parts and solder them together. A soldering station typically consists of a base unit, a power supply, and one or more interchangeable tips. The device heats up the tip to melt the solder, which is then applied to the two pieces that need to be joined.

The KSGER T12 Soldering Station is a variable temperature soldering station, allowing the user to adjust the temperature of their tip depending on their project. This type of device is often preferred by electronics hobbyists and professionals since it provides more control over the heating process than other types of soldering stations. [1]

Parts of a Soldering Station

Main Control Unit

The main control unit of the KSGER T12 Soldering Station is responsible for delivering power to the tip and providing users with feedback about their work. The LCD screen on the front of the station shows temperature, time, status messages, user settings, and more. A rotary knob on the side allows you to select various functions and adjust parameters like the set temperature or sleep time. [3]

Soldering Pencil

The KSGER T12 Soldering Station comes with a soldering pencil that houses the heating element, temperature sensor, and tip. The pencil features a stainless steel shaft for enhanced durability and ergonomics. For added convenience, it can be replaced with any other compatible soldering pencil from the same manufacturer. It is important to note that any incompatible parts may damage the station. [3]

Foam Grip

The foam grip of the KSGER T12 Soldering Station provides comfort and improved control when soldering. The silicone material helps dissipate heat away from the user’s hand while providing a secure hold. This is an especially important feature for extended periods of use. [3]

ESD Protection

The KSGER T12 Soldering Station is designed with Electrostatic Discharge (ESD) protection. This ensures that static electricity will not damage sensitive components during use. With this feature, users can be sure that their work is safe from harm due to electrical interference. [3]

Desoldering Tools

The KSGER T12 Soldering Station comes with a desoldering tool for easy removal of old solder from components. The desolder pump features an adjustable air flow rate and durable construction, making it an essential tool for any soldering project. It is also possible to purchase additional desoldering tools if needed. [3]

Are You Going To Use It Regularly?

If you’re going to use the KSGER T12 Soldering Station regularly, then it would be worth your while to invest in one. The soldering station has a robust, durable design and its powerful 70W iron is capable of withstanding heavy use for hours on end. It also provides precise temperature control settings that let you adjust the heat output according to the task at hand. With its superior features and quality construction, this soldering station is an ideal choice for those who need it for frequent use. [4]

What is the Function of the KSGER T12 soldering station?

The KSGER T12 soldering station is a tool used for joining two metal surfaces together through the use of heat and molten solder. It has a temperature controller to regulate the heat and an LCD screen with adjustable settings that can be used to change the heat output accordingly. The station also includes interchangeable tips, allowing you to switch between different sizes and styles in order to suit your needs. Additionally, the station has a sleep mode and adjustable timers to turn off the power when not in use. This helps extend the life of the machine as well as conserve energy. [4]

What is a Soldering Station Used For?

Soldering is an important process in electronics because it allows electrical components to be securely connected, preventing them from becoming detached or disconnected. It also helps create strong, reliable connections between components that can withstand vibration and environmental changes. The KSGER T12 Soldering Station is a reliable and versatile soldering station that can be used for many different tasks. [4]

How to solder using a KSGER T12 soldering station?

Solderings using a KSGER T12 soldering station is easy and straightforward. Here are the steps:

- Select the appropriate tip size for your project. The tips come in various sizes, so choose carefully to ensure efficient heat transfer from the iron to the workpiece.

- Turn on the power switch located at the bottom of the station.

- Adjust the temperature to the correct setting using the dial on the left-hand side. The temperature will depend on what type of solder you are using and how big the components are that you’re working with, so refer to your specific instructions or do some research to find out what temperature is optimal for your project. [4]

Applications of Soldering

Soldering stations are an indispensable tool for those in the electronics industry. They’re used to solder circuit boards, LED lights, capacitors, and a variety of other electronic components. This makes them an invaluable asset when working on projects that require precision.

The KSGER T12 Soldering Station is especially useful for hobbyists and professionals alike. It has multiple temperature settings that range from 200°C to 480°C, adjustable power outputs of 25W/35W/60W, and a digital LCD display with timer to ensure accurate results. [3]

Selection Criteria for a Soldering Station

When it comes to buying a soldering station, there are certain criteria you should consider. First of all, the wattage is an important factor. The KSGER T12 Soldering Station has adjustable temperature settings from 200-480°C and can handle up to 60 watts of power. This makes it suitable for both hobbyists and professionals alike. [3]

How to maintain an SMD soldering or rework station?

Regular maintenance and care are important to keep your SMD soldering or rework station in top condition. Here are some tips on how to maintain an KSGER T12 Soldering Station:

- Clean the tip of the iron regularly with a damp sponge or wire mesh pad, then tin it with solder. This will help ensure that heat is evenly distributed and can reduce oxidation.

- To protect the tip from corrosion, apply a thin layer of flux to it before use and after each cleaning session.

- Keep the soldering station away from dust and direct sunlight to prolong its lifespan.

- Regularly inspect the power unit for any damages or wear and tear, as well as the tip of the iron for any signs of damage or discoloration.

- Read the manual and take note of any specific maintenance instructions for your model.

- If possible, store all components neatly and separately in an air-tight container when not in use to protect them from dirt and dust. [1]

How to safely use a hot air rework station?

It is important to take precautions when using any hot air rework station, and the KSGER T12 Soldering Station is no exception. Here are some tips on how to use it safely:

- Make sure you have adequate ventilation in the area where you will be soldering. This helps reduce heat buildup and ensures that your workplace remains a safe environment.

- Wear eye protection when using any soldering station, especially when working with hot air rework stations. This helps protect your eyes from splashes and sparks that can be created when the solder melts.

- Always read the manufacturer’s instructions before using a soldering station. Make sure you understand how to adjust temperature and airflow levels correctly.

- Avoid using the hot air rework station in an area that has flammable materials or liquids near it. Always make sure to keep the work area clean and free of debris.

- Make sure all of your equipment is properly grounded before beginning any soldering job, including the hot air rework station. [1]

FAQ

Why use a soldering station?

A soldering station is an essential tool for any electronics enthusiast. Soldering allows you to create electrical connections between components in a circuit, and a soldering station provides the heat necessary to melt the solder and make those connections. The KSGER T12 Soldering Station is a great choice for those who are just starting out with soldering as it’s easy to use and provides reliable results.

What is soldering used for?

Soldering is used to make connections between electronic components, such as connecting wires to a printed circuit board. It’s also commonly used for repairs and modifications of existing electronics, such as fixing broken buttons on a game console controller or adding extra features to an existing device.

What are the 3 types of soldering?

The three main types of soldering are soft soldering, hard soldering, and rework soldering. Soft soldering is the most commonly used type for electronics, and it involves melting a low-melting point alloy (solder) between two surfaces that need to be connected. Hard soldering uses higher temperatures and stronger alloys than soft soldering.

Why is it called soldering?

Soldering is so named because of the low-melting alloy used in this type of electrical connection, which usually contains lead. The word “soldering” is derived from the Latin root soldare, meaning “to make solid.”

What are the 4 types of solder?

The four main types of solder are lead-free, rosin core, acid core, and flux core. Lead-free solder is the most common type used in electronics today due to environmental concerns. Rosin core solder is designed for electrical connections and contains a resin that acts as a flux while it melts. Acid core solder is designed for plumbing applications and contains an acid flux that helps to create a strong bind between two surfaces. Flux core solder is designed for welding applications and contains a flux within the soldering alloy itself.

What is the difference between soldering and welding?

Soldering and welding are both processes used to join two pieces of metal together, however there are a few key differences between the two. Soldering involves melting a low-melting point alloy (solder) between two surfaces that need to be connected, while welding uses high temperatures and stronger alloys. Welding also requires a filler material, such as rods or wire, while soldering does not. Additionally, welding creates a stronger bond than soldering.

What are the two main types of soldering?

The two main types of soldering are soft soldering and hard soldering. Soft soldering is the most commonly used type for electronics, and it involves melting a low-melting point alloy (solder) between two surfaces that need to be connected. Hard soldering uses higher temperatures and stronger alloys than soft soldering.

Useful Video: KSGER T12 Soldering Station Review 3.1S Version

Conclusion

In conclusion, the KSGER T12 Soldering Station is a great choice for hobbyists and professionals alike. Its versatility and advanced features make it an ideal choice for all kinds of soldering projects. With its temperature control technology, you can easily adjust the heat to suit your needs. Plus, it’s intuitive user interface makes it easy to use even for beginners. With its wide range of accessories, you can customize it to suit your needs. The KSGER T12 Soldering Station is definitely a great value for the money and an excellent choice in soldering stations.

If you’re looking for a reliable, high-performance soldering station that’s easy to use, then the KSGER T12 Soldering Station is definitely worth considering. Give it a try, and you won’t be disappointed!

Happy soldering!

References

- https://tameson.com/pages/soldering-station

- https://www.tilswall.com/blogs/news/what-is-a-soldering-station-used-for

- https://scanditronictech.com/resources/smd-soldering-rework-stations/

- https://uk.rs-online.com/web/content/discovery/ideas-and-advice/soldering-stations-guide

Leave a Reply