Jump rings are a simple and easy way to attach findings in DIY jewelry projects. It is a fast, effective method of making links for beaded necklaces or chains for earrings. Jump rings can also be used to create clasps for bracelets, anklets, and other types of jewelry pieces.

This blog post will go over how to solder jump rings so that they stay closed permanently. This article includes step-by-step instructions on what you need and how to solder the jump ring properly so that it stays shut without falling apart or opening up again later!

Things You’ll Need:

- A solder wire;

- Borax flux;

- Needle-nose pliers;

- A small and fine paintbrush;

- A charcoal block;

- A soldering torch;

- A pickle solution;

- Copper tongs;

Soldering Jump Rings: A Step-by-Step Guide

- Extra-easy solder temperament is one of the easiest types to work with. Only one sort of solder, which is low-temperature soldering, needs a reduced heat environment. The solder that melts at a very high temperature is not required for jump rings since they are made of wire. Using tin snips that have the maximum blade length of 0.03 inches (1 mm), you may cut extremely tiny chips quickly and easily;

- Place all of the cut solder pieces in a container that has been designated for it and does not contain any other types of soldering;

- If the ring is tiny, use needle-nose pliers to open the jump ring;

- Apply flux to both ends of the opened jump rings with a tiny, fine paintbrush. Flux is a chemical that helps the solder flow into the join. Borax is one kind of flux that is frequently used;

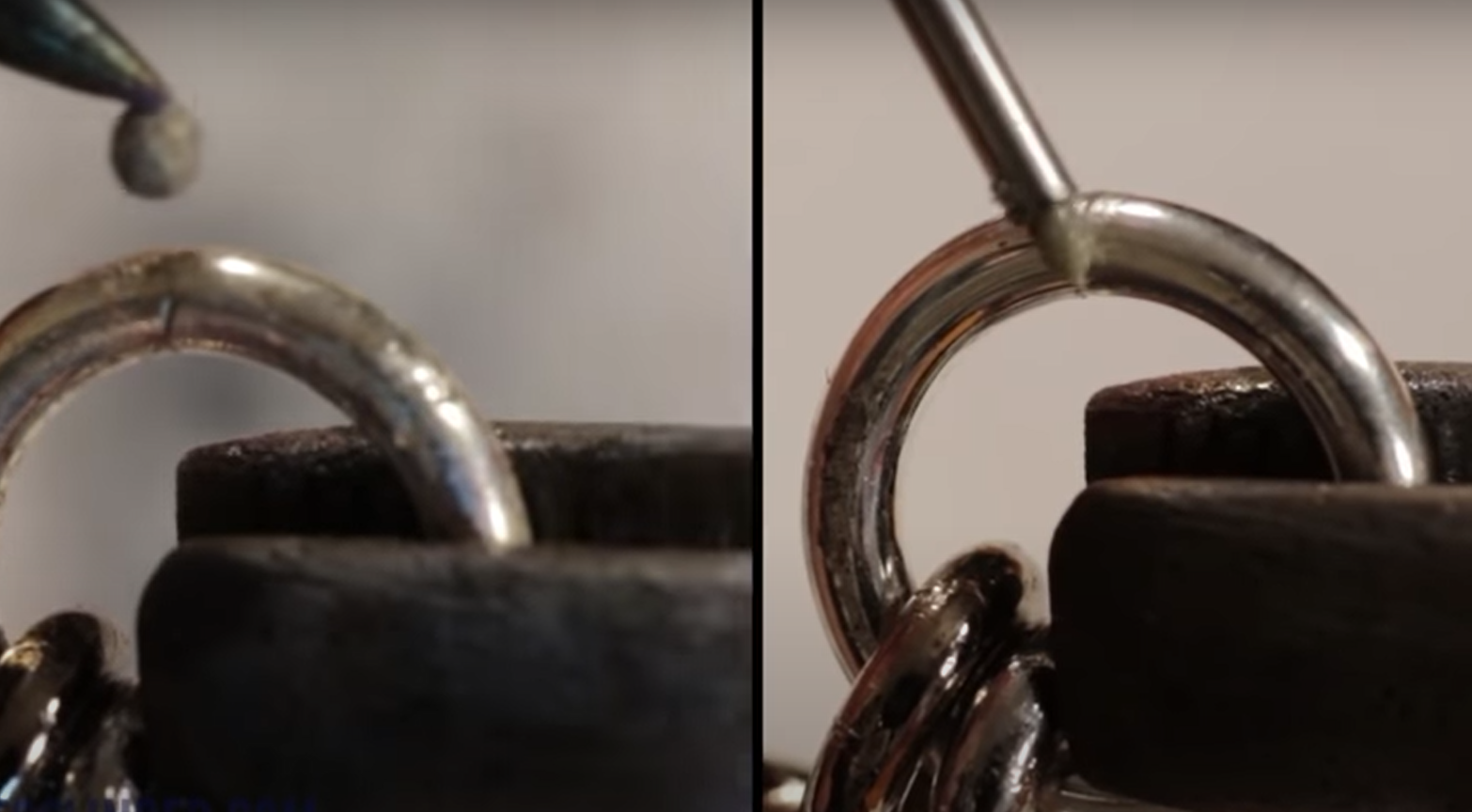

- With the pliers, squeeze the jump ring shut so that the two ends are flush with one another;

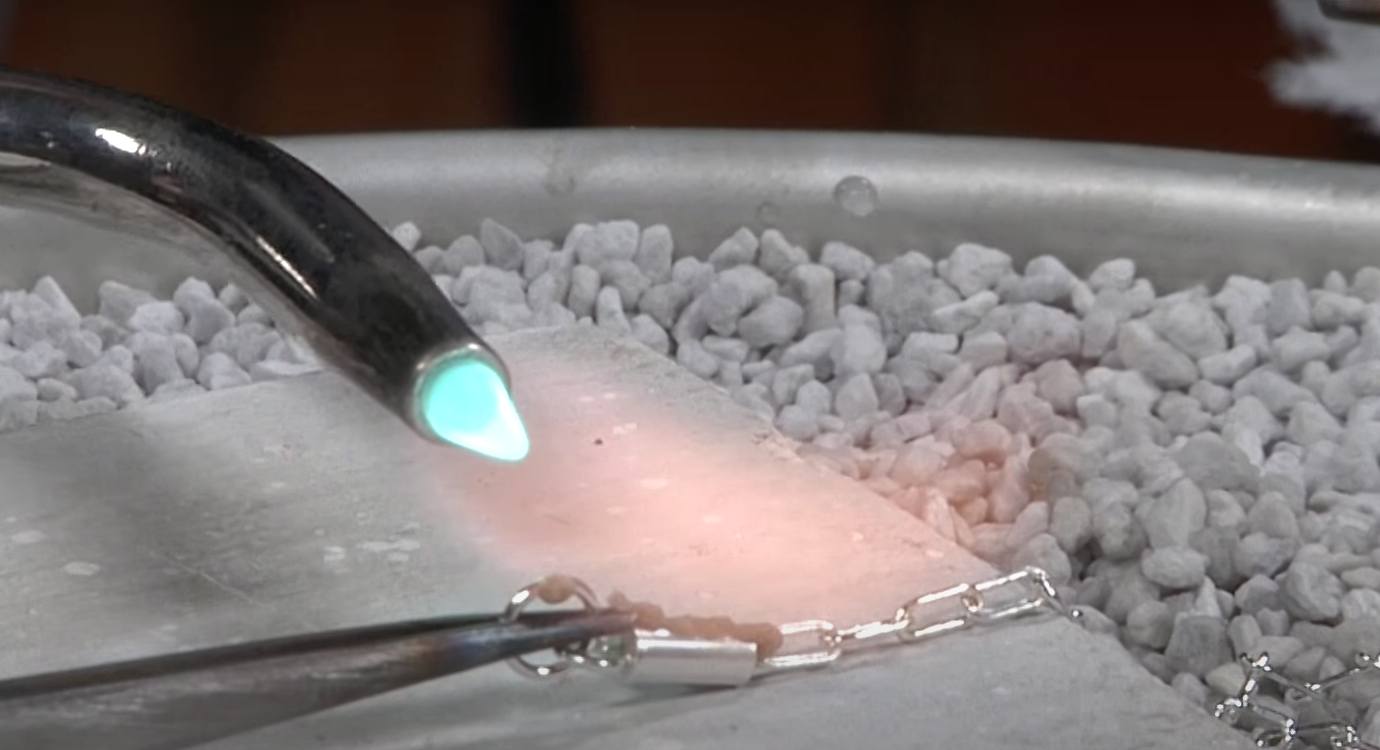

- Place the jump ring on a charcoal block. The joint should be touching the block before soldering jump rings;

- With the point of the tiny, fine paintbrush, pick up one extra-simple solder chip;

- Place the soldering chip on the connection;

- Turn on a soldering iron/torch;

- Heat the jump ring and charcoal block together, but do not heat the solder. The solder will flow to the hottest place when you weld metal jump rings;

- When the soldering is complete, wait for the solder to melt. The solder will be transparent at this point;

- Check to see if the solder has flowed;

- This whole process will be completed in a matter of minutes. Remove the heat as soon as possible;

- Place the jump ring in a pickle solution to clean it. A pickle is a solution that strips away an outer layer of oxidation from the soldered metal;

- Wait until all of the jump rings are soldered, as they may all be added to the pickle together;

- Using copper tongs, remove the pickle solution’s jump rings;

- Clean the jump rings with water;

- Repeat the procedure on all jump rings requiring soldering;

Tips and Warnings:

- Use a fine-tip soldering iron;

- Be sure to clean the jump rings in pickle solution and rinse them with water after they are finished being soldered. It is important that you do not touch these pieces of jewelry, because the pickling process may irritate your skin;

- Solder wires should never be cut shorter than 0.02 inches long, or else it will become difficult for the solder to flow into their join properly; and

- If you use too much flux on tiny wire connections like this one when soldering jump rings, then there can be some excess dripping onto other areas where it does not belong;

- The extra flux could remove the color from gemstones or even burn holes through your fabric;

- If you have a large number of jump rings to solder, it may be helpful to use a fiber-soldering pad instead of the charcoal block so that there is ample space for all of them;

- Be sure not to burn yourself when welding extra-easy solder temperaments because they can work extremely quickly;

Also, remember that tin snips should never come into contact with other types of metals, or oxidation from copper wire will transfer onto their surface and make it difficult to cut through materials smoothly without breaking apart prematurely; and

Never touch your skin after using flux or pickle solution on these pieces since this could irritate your hands severely.

How to Solder Jump Rings – Comparison Table

Soldering jump rings is a crucial skill in jewelry making and metalworking. It involves joining metal rings using solder to create secure connections. This table provides a comparison of different indicators to consider when soldering jump rings, including the type of solder, suitable metals, the strength of the joint, and the skill level required.

| Indicator | Soft Solder | Hard Solder | Medium Solder |

|---|---|---|---|

| Type of Solder | Lead-based solder | Contains more silver | Mix of silver and other metals |

| Suitable Metals | Best for delicate or thin metals like copper and brass | Suitable for heavy-duty metals like stainless steel | Works well with a variety of metals like silver and gold |

| Strength of Joint | Less strong compared to other solder types | Creates a very strong joint | Moderate strength, suitable for most jewelry projects |

| Skill Level Required | Beginner-friendly due to ease of use | Requires more experience and precise control | Intermediate level, offers a balance between ease and control |

This updated table provides a comparison of three types of solder commonly used for soldering jump rings: Soft Solder, Hard Solder, and Medium Solder. The indicators compared include the type of solder used, the suitable metals to work with, the strength of the joint formed, and the skill level required to handle each type of solder.

Type of Solder: Soft solder is lead-based, making it easy to work with but results in joints that are less strong compared to hard solder. Hard solder contains more silver, which provides excellent joint strength, ideal for heavy-duty metals. Medium solder is a mix of silver and other metals, offering versatility for various jewelry-making applications.

Suitable Metals: Soft solder is best for delicate or thin metals like copper and brass due to its lower melting point. Hard solder is suitable for heavy-duty applications and works well with metals like stainless steel. Medium solder is versatile and can be used with a variety of metals commonly used in jewelry making, such as silver and gold.

Strength of Joint: Hard solder creates the strongest joint, providing excellent durability for jewelry pieces that may undergo stress. Soft solder, while easier to work with, forms joints that are less strong compared to hard solder. Medium solder strikes a balance, offering a moderate joint strength suitable for most jewelry projects.

Skill Level Required: Soft solder is beginner-friendly due to its ease of use and lower melting point. It is suitable for those new to soldering. Hard solder demands more experience and skill in handling higher temperatures and precise control during the soldering process. Medium solder is ideal for intermediate-level artisans, offering a balance between ease of use and control when soldering jump rings.

Check more soldering guides to improve your knowledge:

FAQ

What kind of jump rings can you solder?

Any jump ring can be soldered. All jump rings should be soldered together to ensure that parts in your designs do not disconnect from one another. In reality, closing every jump ring in your projects might be time-consuming and costly, but if you pick the appropriate size and thickness of an open jump ring, it may not be necessary.

How do you seal jump rings without soldering?

Jump rings can be sealed without soldering if you use a large enough jump ring to fit the design. You will need to make sure that your jewelry components can’t separate from one another, otherwise, they may fall off and get lost. In most cases, using a sealant rather than solder is not recommended because of leaks or even complete breakage while trying to open it up again for repairs or resizing purposes.

How do you solder a jump ring on a chain?

You can solder a jump ring to a chain by cutting off the excess portion of your open jump ring and placing it on top of another component in your design. If you have already closed up one side or end of your jump rings, do not worry about their orientation because they should all be able to fit together without any problems.

It is also possible that you need to add an extra piece to your project if there isn’t enough space for both components when connecting them with solder alone. In this case, keep adding parts until everything fits into place properly before applying heat from a torch or even gas burner set at a low temperature. Using high temperatures will result in melting and deforming metal that may make repairing designs difficult if not impossible!

How do you solder a jump ring at home?

Solder jump rings at home by first placing the ring you need to solder directly on top of another piece. You can even use a pair of pliers or tweezers for this process since it may be difficult to handle one component with your fingers alone. Afterward, apply flux paste around both components and wait for a few moments before using a torch set at low temperatures to melt down the solder inside open jump rings without burning anything else up!

How do I make sure jump rings stay closed?

After you have soldered jump rings together, they should not open unless heated again to soften the solder. You can test if your designs stay closed or pop open by gently tugging at different areas of components such as chains and even earrings that may be connected with jump rings while wearing them!

If pieces do not fall off after trying this method out, then it is safe to say that connections are solid and strong enough without any leaks forming over time.

You could also use a pair of pliers for closing up an end or side of the open jump ring using moderate pressure before inserting it into another part in your design. However, keep in mind that high temperatures will weaken metal parts because heat changes metals’ properties when exposed to too much heat from

How do I stop my jump ring from coming apart?

The only way to make a jump ring permanently stay closed is to solder it together. Some jump rings are pre-soldered, while others need to be soldered shut using a butane torch. You may also want to consider using split rings (imagine a key ring) which are quite secure [1].

What is needed to solder jewelry?

To solder jewelry, you will need the following [2]:

- A butane torch (or propane can with a small tip) and striker or matches;

- Flux paste;

- Solder wire;

- Pliers for holding objects in place while soldering them together;

- Kiln brick or charcoal block;

- Optional: tweezers;

You can find flux paste sold in tubes or even jars at your local craft store if you don’t have any on hand already. It is not recommended to use regular old super glue because it usually contains acids that may affect the metal’s color over time, especially when exposed to air and water which are both bad for jewelry parts made from copper! There are also other types of glues available such as E6000 that work well with holding metals together so try out different kinds yourself until you find one that works best for your needs!

How do you solder 14k gold jump rings?

You may use “plumb solder”, “medium” or “hard” solder for 14-karat golden jump rings. Solders with a lower gold content will melt more readily, and it’s recommended for minor repairs. Use “repair solder”, “easy” solder, or silver jump rings below 14 karats when repairing jewelry that has been plated [3].

Why do my jump rings keep opening?

If your jump rings keep opening up, then you may be applying too much heat from a butane torch or even gas burner that will make the solder inside of the open jump ring melt and deform metal parts! It is best to use low-temperature settings for most metals when heating them since high temperatures can change their properties over time.

You should also consider using split key rings (imagine a regular old key ring) instead of soldering closed because they are quite secure. You could always add an extra dab of glue just in case if you want something more permanent that requires less maintenance later on down the road.

What is the difference between a split ring and a jump ring?

Split rings are simply key ring hoops that have been split down the middle to make them open and close. You can easily attach things onto these by sliding your design in between the two ends of the hoop once opened up before pushing it back together again. They look like infinity signs when closed that is why they work well with chokers, necklaces, earrings, bracelets, or even zipper pulls!

Jump rings, on the other hand, are circular metal circles that link jewelry components together using wire twists or another method such as soldering if you want something much more permanent than glue alone. Jump rings come in all sorts of shapes and sizes whether large or small depending on how many wires were used inside to twist around each other [4].

Can you fuse copper jump rings?

Sterling silver, copper, and brass jump rings can’t be fused/welded. Soldering is necessary if you want to work with metals other than fine silver and pure gold [5].

Can you solder a broken ring?

You can solder a broken ring together using flux paste and soldering wire or brazing rod. Place the ends of your split rings inside of one another before applying heat to melt them back together again.

Can I use super glue on gold?

Do not use super glue on gold as it will ruin the color over time that is why flux paste works best for this! You can also try out other types of glues such as E6000.

What size jump ring do I need?

You can use jump rings of any size you want depending on how large or small your design is. Make sure to keep in mind the wire thickness when choosing a ring because it should be strong enough to support what’s attached inside without opening up too much over time.

What type of solder should I use for jump rings?

You should use solder that is specifically designed for jewelry-making, such as silver solder or gold solder, depending on the metal of your jump rings.

Can I use a regular soldering iron for soldering jump rings?

No, it’s best to use a jewelry soldering torch or a micro torch with a fine flame for soldering jump rings as they provide more control and precision.

How do I prepare the jump rings for soldering?

Before soldering, make sure the jump rings are clean and free from any dirt, oil, or oxidation. You can use a jewelry cleaning solution or pickle solution to clean them.

What safety precautions should I take when soldering jump rings?

When soldering, always work in a well-ventilated area to avoid inhaling fumes. Wear protective goggles and heat-resistant gloves to protect your eyes and hands from any accidents.

How do I position the jump rings for soldering?

When soldering jump rings, it’s essential to have them properly aligned and held in place securely. You can use tweezers or a third hand tool to position them correctly before soldering.

What soldering technique should I use for jump rings?

The most common technique for soldering jump rings is the sweat soldering method. This involves applying solder to one jump ring and then carefully heating it until the solder flows and attaches the other jump ring.

How can I ensure a strong solder joint for my jump rings?

To achieve a strong solder joint, make sure the jump rings fit tightly together without any gaps. Also, ensure that the solder flows evenly and completely covers the joint for a secure connection.

What do I do if I accidentally melt the jump ring while soldering?

If you accidentally melt the jump ring during soldering, you’ll need to remove the damaged jump ring and start with a new one. It’s essential to practice patience and control while soldering to avoid such mishaps.

Can I solder jump rings made of different metals together?

It’s generally not recommended to solder jump rings made of different metals together, as their melting points and properties may vary, leading to an unreliable solder joint.

How do I finish the soldered jump rings?

After soldering, you can clean the jump rings again and polish them to remove any oxidation or discoloration. This will leave you with a professionally finished piece of jewelry.

Useful Video: Learning How To Solder – Soldering Jump Rings – Making Your Own Jewellery

References:

- https://www.thesprucecrafts.com/fixing-jump-ring-problems-2051210

- https://www.craftsy.com/post/jewelry-soldering-tools/

- https://www.wikihow.com/Solder-Gold

- https://craftminute.com/the-difference-between-a-jump-ring-and-split-ring/

- https://www.interweave.com/article/jewelry/soldering-vs-fusing-learn-the-pros-and-cons-in-jewelry-making-and-when-to-do-which/

Leave a Reply