Switched reluctance motors (SRMs) are a type of electric motor that has been growing in popularity in recent years. They offer many advantages over traditional brushed DC and induction motors, including high efficiency, low noise, and long life. In this article, we will discuss what a switched reluctance motor is, the benefits it offers, and how to choose the right one for your application.

Definition of Switched Reluctance Motor

It uses no permanent magnets or electrical windings on its rotor, instead relying on electromagnetism produced by the stator winding when switching currents. The SRM has many advantages compared to other motors including its low cost, robust construction and maintenance-free operation.

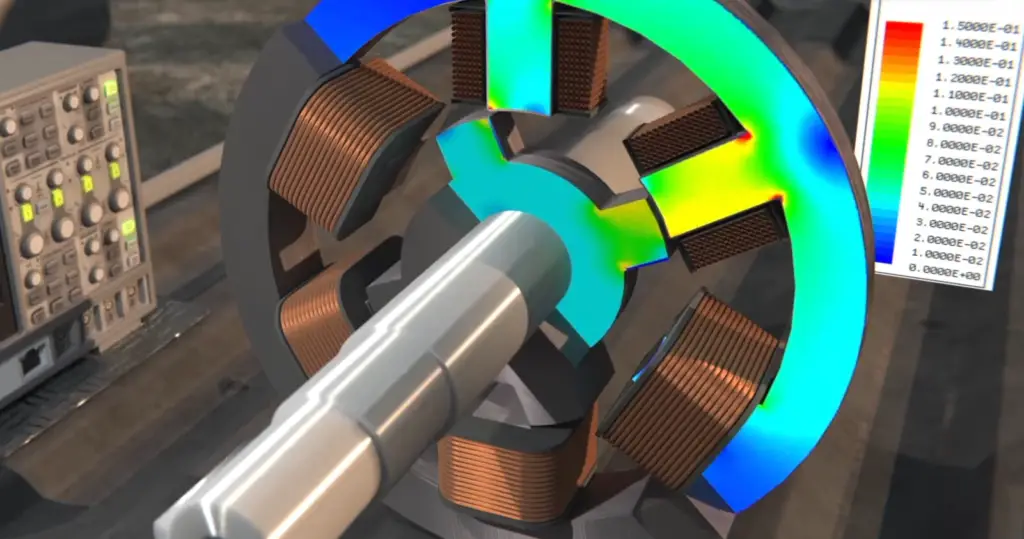

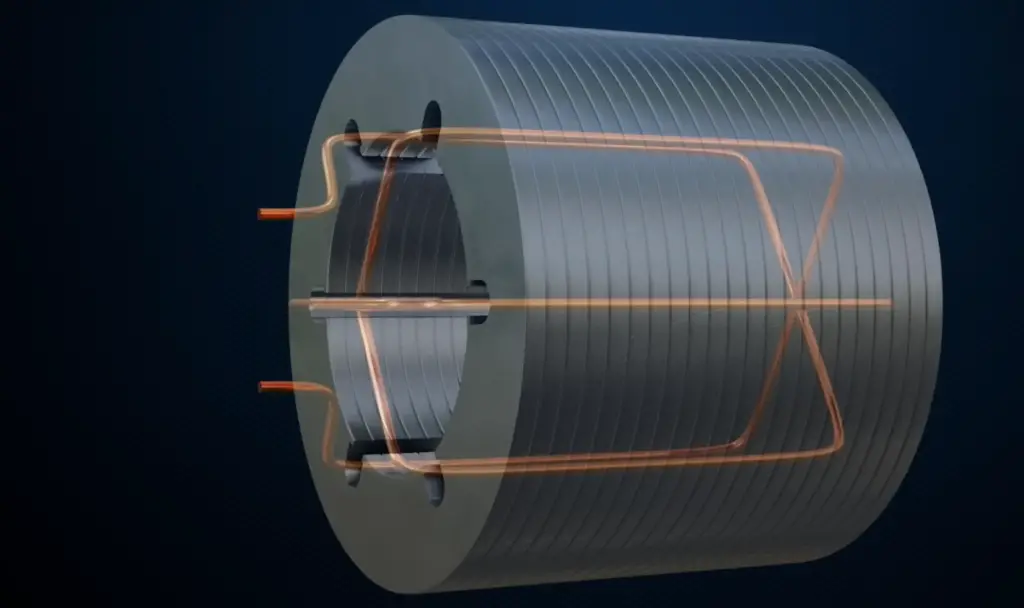

The design of a switched reluctance motor consists of 6- stator poles as well as 4 rotor poles. The rotor poles have salient cutouts that line up with the stator winding. When a current is applied to the stator coil, it induces an electromagnetic field in the rotor pole which causes it to turn in response. This process is known as magnetic reluctance and allows for very high torque levels at low speeds with minimal losses due to friction. [1], [2], [3]

Working Principle of a Switched Reluctance Motor

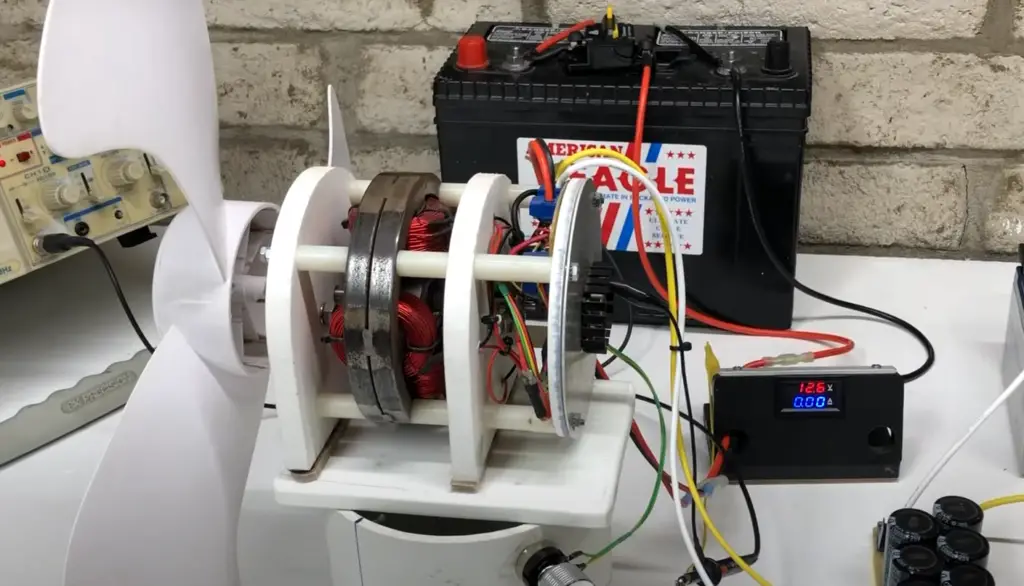

They can be used in a variety of applications, from industrial automation to consumer appliances and automotive systems.

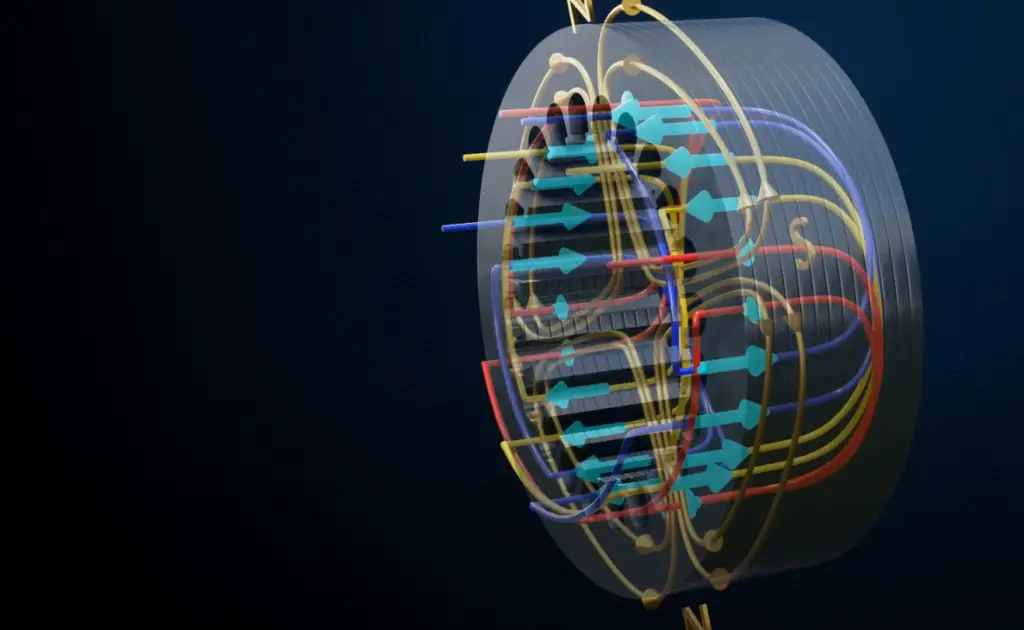

The working principle of SRMs is built on the concept of variable reluctance, meaning that the rotor in this type of motor continuously searches for its path with least resistance.

By utilizing a power electronics switching circuit, forming a rotary magnetic field is achievable. The rotor and stator’s air gap plays an integral role in the reluctance of the magnetic circuit; thus, by adjusting this space we can adjust the motor’s reluctance as well. [1], [2], [3]

Types of Switched Reluctance Motors

Switched Reluctance Motors come in a wide variety of sizes and types, and can be adapted for specific applications. There are two main types of SRMs: linear and rotary.

Linear SRM

A Linear SRM, or surface-retrieval model, is a type of machine learning algorithm that can be used to predict the behavior of surface processes. This predictive power means that it can be useful for predicting the responses of systems with complex dynamics, such as those found in physical and chemical processes.

The system works by training a computer model to accurately predict the behavior of different surfaces based on input data. This data can include measurements from sensors placed directly on the surface, visual imagery, and other sources. By combining these inputs into a single model, Linear SRM can be used to make predictions about how a given system will react under various conditions. These predictions can then be used to help optimize operations and processes for improved efficiency and productivity. Linear SRM can also be used to reduce costs by predicting when process changes may be necessary before they occur, allowing companies to react quickly and efficiently to changing conditions. In addition, the model can be used to identify areas of potential improvement or optimization, allowing for further improvements in efficiency.

Rotary SRM

A Rotary SRM, or rotary-type surface mount machine, is a type of automated assembly equipment used to assemble components or products in the electronics industry. It works by positioning and placing components onto a circuit board with precision accuracy. The components are usually small and delicate such as integrated circuits (ICs), resistors, capacitors, connectors and switches.

These machines utilize advanced software to control their movements while they place the components with great accuracy onto the circuit boards that make up electronic devices. The speed and placement accuracy of these machines ensure high quality products are produced quickly and efficiently. Rotary SRMs can be scaled to fit any production environment from low volume prototyping to mass production applications. Additionally, many models are available that allow for custom solutions tailored to specific customer requirements.

Rotary SRMs are available in two types: radial and axial. Radial machines are the most common type and are used for larger components that require more precise placement accuracy. Axial machines, on the other hand, can be used for smaller components with less precision requirements. [1]

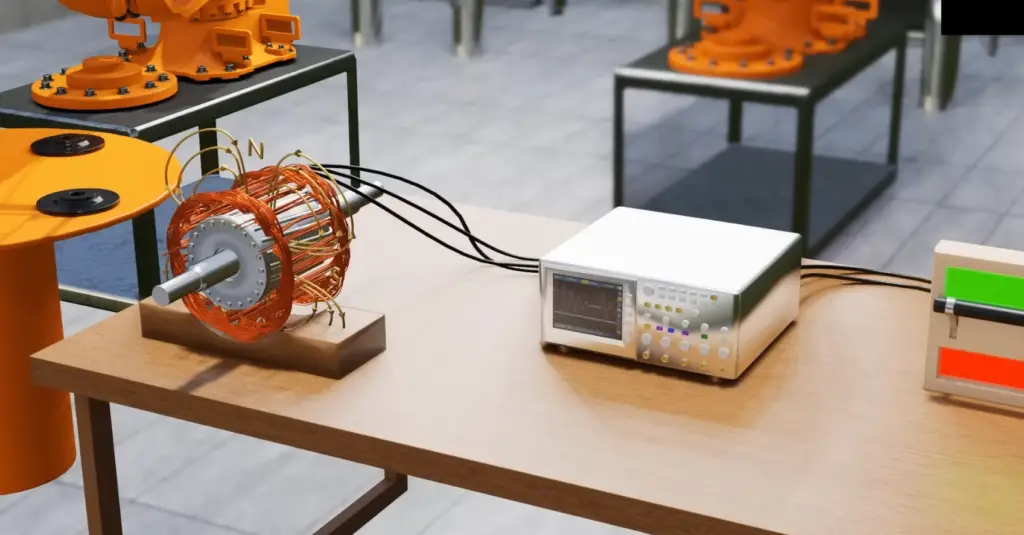

Construction of Switched Reluctance Motor

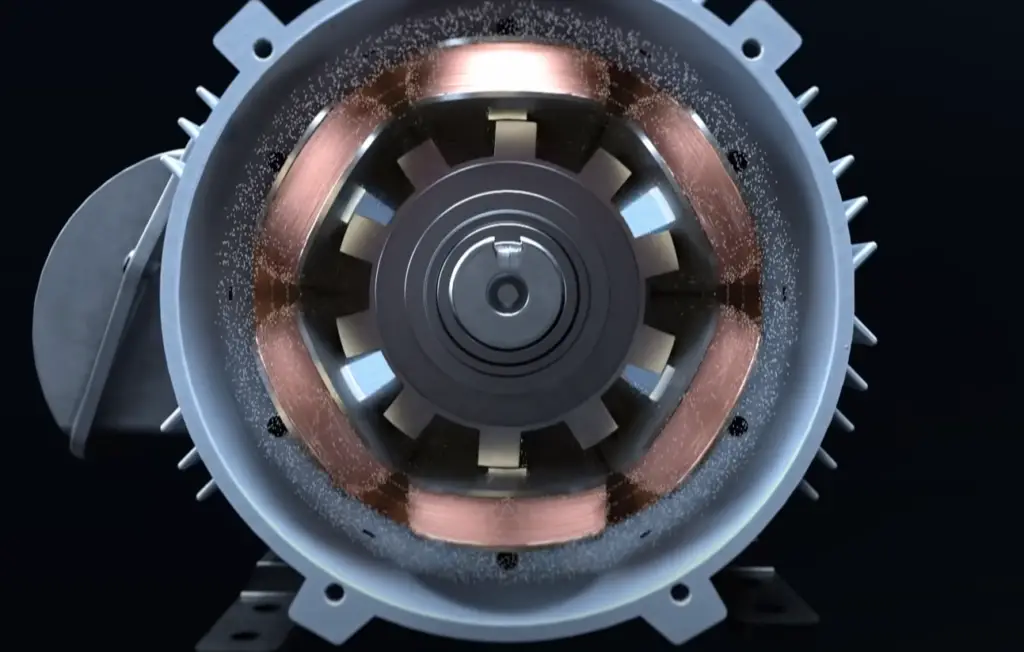

Constructed from 6 stator poles and 4 rotor poles, the switched reluctance motor is designed with projected silicon steel stampings for optimal performance. The number of poles in the stator can either be an odd number or even number. Still, most of the electric motors have an even number of poles because it allows for an easier and more efficient electromagnetic winding pattern.

When the pole positions are reversed, then the field coils have to be connected in series. This means their magnetomotive forces (MMF) get added up – this is referred to as phase windings. A set of coils or a single-coil can make up phase windings. By connecting each winding to the motor terminal, these can be properly connected to the output terminals of a power semiconductor switching circuit with an input DC supply.

Using steel stampings, the rotor can be designed with externally projected poles that are different from the stator ones. Generally speaking, when constructing existing motors, comprehensive pole number planning is required; therefore most of them possess either 4 or 6 rotor poles in correspondence to their particular count of stator poles (6 and 8).

The shaft of the rotor is fitted with a position sensor, which then produces signals responsible for controlling multiple components in the power semiconductor circuitry.

Frequently, the rotor and stator are both equipped with a projected pole crafted from soft iron and silicon stampings to minimize hysteresis losses. The stator of the motor has a field winding but the rotor does not. By connecting each winding in-series with its opposite pole inside the stator, it will increase the circuit’s magnetomotive force substantially. [1], [2], [3]

History of Development of Switched Reluctance Motor

Switched Reluctance Motors (SRMs) have been around since 1838 when W. H. Taylor petended the first electric motor. Since then, SRMs have undergone several modifications and improvements to become more efficient, reliable and cost effective motors for use in industrial applications.

Initially SRMs were used to propel locomotives, and found application in mining, chemical and general industry. But since then, they have improved and become much more flexible.

For instance, the 1990s saw a merging of computer-controlled flexible manufacturing systems and main warehouses with robots for assembly. This combination enabled efficient production processes to be developed. To ensure efficiency, quality, automation and harmony in the production process throughout the plant, a computer was used to precisely regulate the delivery of materials and components. Through the introduction of enhanced dedicated control chips and integrated power devices, design and manufacturing advancements have enabled improved performance levels for switched reluctance motors. This has opened up a great potential market with extended applicability for this motor technology. [3]

Advantages of Switched Reluctance Motors

Now that you have a decent grasp of the background and core technology behind the SRM, it’s time to discuss the advantages these motors provide.

Simple VFDs

VFDs, also known as Variable Frequency Drives, are electrical systems designed to adjust the speed at which motors and other connected equipment operate. By using a VFD, electric motors can be sped up or slowed down depending on the specific needs of an application. VFDs require power from a three-phase AC source that is then converted into DC voltage before being reconverted back into variable frequency AC output for motor control. This allows for greater accuracy and flexibility when controlling motor speeds than what can be achieved with traditional mechanical controls such as belts or pulleys.

One of the major benefits of SRM technology is that the VFDs of this motor are much simpler than those of traditional AC motors. This makes it a cost-effective solution for many applications. SRM VFDs are also more reliable and efficient than other types of drive technology, as it does not require an electronic commutator or brushes to switch phase currents.

Very simple operation

One of the primary advantages of SRMs is that they are very simple to operate. As SRMs do not possess any permanent magnets, there is less reliance on complex control circuits and the motor can be directly connected to the power supply. This simplifies the design process and reduces cost significantly as no additional components need to be purchased for operation.

Applicable for high-speed applications

This motor can reach speeds of up to 100k RPM with no load, and its power output increases by a factor of three or four when compared to an induction motor running at the same speed. It’s also capable of reaching maximum torque with only minimum current draw due to the absence of windings within the stator.

It doesn’t use any additional ventilation system

Unlike other types of motors, SRMs do not need to be teamed with a separate ventilation system. This is because they are based on the principle of electromagnetic induction, which tends to generate its own cooling while operating.

More affordable

The most obvious benefit to SRMs is their lower cost compared to other types of motors. This makes them particularly attractive for use in budget-constrained projects or applications where multiple motors are needed. Generally, the cheaper price tag is due to the fact that the motor does not require any costly permanent magnets and brushes. Also, as discussed above, one of the main components of these motors —the coil— is relatively inexpensive too.

High fault tolerance

Another of the primary benefits of SRM’s is their high degree of fault tolerance. This means that it’s much more difficult to damage them if something goes wrong during operation. This is especially useful in applications where an unexpected overload or sudden shock could be extremely destructive to normal motor types, such as robotics and industrial automation.

Works with both simple two-phase or three-phase pulse generator

Another of the most notable benefits of SRMs is that they can work with both simple two-phase or three-phase pulse generators. This makes them far more flexible than other motor types, since these controllers are generally easier to build and maintain. In addition, they have no need for high voltage switching components like thyristor’s (SCRs) which makes them well suited for use in sensitive applications where safety is paramount.

Phase losses do not change the operation of the motor

One of the unique features of an SRM is that it can operate in a linear fashion. This means that when current is applied, there is no change in the motor’s performance due to losses from the inductance of winding resistance. The torque-speed relationship will remain unchanged as long as there are no external disturbances present. This makes controlling and maintaining consistency for these motors much easier than other types of motors, like brushed DC or AC induction motors.

Is completely self-starting

A great advantage of the SRM is that it does not require any external starting device, like a capacitor or secondary winding. This makes it a great choice for applications in unsupervised environments.

The lack of this requirement also reduces cost and complexity, particularly when compared to induction motors requiring capacitors, which add considerable cost to their operation. [1], [3]

Disadvantages of Switched Reluctance Motors

As great as they are, switched reluctance motors do have a few drawbacks. In this section, we’ll explore some of the main disadvantages associated with this motor type. It’s important to understand the limitations in order to make an informed decision when considering whether or not to use a switched reluctance motor.

Less torque capacity

One of the main disadvantages of using a switched reluctance motor is that they are not able to produce as much torque as other motor types. Torque capacity is an important parameter when it comes to measuring and evaluating the performance of a motor. It represents the maximum amount of torque that can be transmitted by a motor, expressed in inch-pounds or newton meters. In simple terms, it is the measure of how much force a motor can apply against another object at any given time.

They are quite noisy

Another of the main disadvantages of a switched reluctance motor is that it can be quite noisy. This noise comes from the constant switching and pulsing associated with its operation. Depending on the application, this sound may not be ideal and could require extra measures such as acoustic insulation to reduce its impact.

Can create a torque ripple during high speed operation

Another thing you have to keep in mind when using a switched reluctance motor is that it can generate torque ripple during high speed operation. Torque ripple is the variation in motor torque that occurs due to imperfections in the motor design or when the torque output varies significantly from its average value. It is typically caused by uneven air gaps between the rotor and stator windings, misalignment of magnetic fields, fluctuating load conditions, or electrical noise. Torque ripple can have an adverse effect on system performance, as it can cause unnecessary vibrations and reduce efficiency.

It uses an external rotor position sensor

One of the primary drawbacks of a switched reluctance motor is that it requires an external rotor position sensor. This means more components and cost associated with the motor, as well as additional complexity for installation. It also means a greater chance for error in the system, since any misalignment or malfunction of these sensors can lead to reduced efficiency and performance from the motor.

Requires large size capacitors

Another thing some users have to consider is the size of the capacitors required for a switched reluctance motor. The larger these are, the more expensive and difficult to install they become. In some cases, this can be prohibitively costly for many people.

The reason for this – is that SRM generates harmonics at high speeds, and the capacitors are used to reduce this. So while they might seem like an extra cost at first, they can be essential for achieving optimal performance. [1], [3]

FAQ

What is a switched reluctance motor used for?

SRMs are used in a range of applications, such as pumps, fans, compressors, and motors for robotics. SRMs are also used in industrial machinery for motion control, such as in conveyor systems. For these applications, the controllability of an SRM is a huge advantage over other motor types.

It’s worth mentioning that SRMs have low torque output but high efficiency. As a result, they’re often used in applications that don’t require large amounts of force, such as air conditioning and refrigerator motors.

What is the difference between reluctance and switched reluctance motors?

The major difference between a reluctance motor and a switched reluctance motor is the way in which they are controlled. A reluctance motor relies on the natural magnetism of its core to induce current in its coils, while a switched reluctance motor requires an external source to control the current flowing through its coils. This allows for much more precise control over the torque output of the motor.

Switched reluctance motors also have simpler construction than their traditional counterparts, as they do not require permanent magnets or complex electronic controllers. Additionally, they are highly efficient and cost-efficient, making them ideal for applications where low power consumption is critical.

What is the advantage and disadvantage of switched reluctance motors?

The main advantage of a switched reluctance motor is its simplicity. It has just one stator winding and no permanent magnets, making it more affordable than other types of motors. Additionally, since there are fewer components in the motor, they require less maintenance and can withstand higher temperatures with greater efficiency.

The main disadvantage of a switched reluctance motor is the noise generated due to the rotor and stator interacting. This noise can cause a reduction in efficiency and make it difficult for machines to operate without further sound dampening measures. Additionally, switched reluctance motors usually have smaller torque output than other types of motors, making them less suitable for certain applications where high torque is needed.

What is a switched reluctance motor Mcq?

Unlike other electric motors, SRMs do not rely on an external field source such as windings or electromagnets; instead they use the natural phenomenon of magnetic reluctance to spin the rotor when a current is applied. The result is a highly efficient and reliable motor with no need for brushes, commutators, or contactors.

SRMs are composed of two basic parts: a stator and rotor. The stator consists of an array of electromagnets that produce alternating magnetic fields. As the current passes through these electromagnets, they create opposite poles which interact with the rotor’s magnetically permeable material creating a torque that rotates it. The rotor is typically made out of steel laminations that allow for the efficient transfer of energy from the stator to the rotor.

Useful Video: Types of Motors used in EV | Single, Dual, Three & Four Motor Configuration in EV

Conclusion

Switched Reluctance Motors (SRMs) are a unique and interesting form of electric motor that offer many advantages over other types of motors. They are smaller, more efficient, and require less maintenance than traditional induction or brushless DC motors. SRMs can be used in a variety of applications from automotive to industrial machinery, with the potential to revolutionize the way we use electricity in our everyday lives.

In this article we have covered the basics of SRMs, their advantages and disadvantages, and their history. We have discussed how they are constructed and how to choose an SRM for a specific application. We have also looked at some of the challenges associated with using these motors, such as noise.

Ultimately, whether or not you decide to use an SRM in your project will depend on its exact specifications, the amount of power required, the purpose for which it is being used, and other factors. However, by considering the information presented here you will be in a better position to make an informed decision that best suits your needs.

Using switched reluctance motors can open up new possibilities for engineers and designers alike. They can help make high-power projects more efficient, both in terms of cost and energy usage. With the potential to revolutionize our use of electricity, SRMs are definitely worth looking into for any project that requires reliable and powerful electrical power solutions. Thanks for reading!

References

- https://www.elprocus.com/switched-reluctance-motor-working/

- https://www.linquip.com/blog/switched-reluctance-motor/

- https://www.utmel.com/blog/categories/motors/what-is-a-switched-reluctance-motor

Leave a Reply