Solder is an important element used in electrical wiring and other electrical devices, but understanding its conductivity can be confusing. Whether you are a beginner or a professional technician, it’s important to understand whether solder is conductive so that you can best install the necessary elements for your project. In this blog post, we will explore what makes solder conductive and discuss the types of solder available to ensure your electrical projects have the most reliable connections possible. Understanding soldering techniques and how different solders work together will help equip you with the proper knowledge needed for any successful electrical application. Let’s dive into learning about solder and its essential characteristics when it comes to electricity!

Is Solder a Conductor or Insulator?

Its use in many electrical and electronic applications has made it an invaluable part of our modern world. However, when it comes to electricity, the question arises – is solder a conductor or insulator?

The type of solder being used affects the answer. Pure lead solder is an excellent conductor, making it ideal for creating electrical connections between wires and components. On the other hand, tin-based solders are much less conductive than their lead counterparts, but they can still be used successfully in some situations.

It’s important to note that even if a particular type of solder does not function as a conductor, it can still provide an electrical connection between two components. This is due to the ability of solder to create a mechanical bond between the two pieces of material. Solder also helps reduce any electrical interference from nearby wires or components, which can improve performance and reliability. [1]

Is Solder a Bad Conductor?

The answer to this question is both yes and no. It depends on the type of solder being used, as well as how it is applied. Solder can be a good conductor if it is applied correctly, with adequate heat and pressure. If the solder joint is thin or not properly heated, however, it may not create a reliable electrical connection between components and act as an insulator instead. In general, though, solder is considered a less conductive material than metals like copper or aluminum. As such, when soldering electrical components together, care should be taken to ensure that proper technique is followed in order to achieve efficient connections. Additionally, different types of fluxes can be used to improve the conductivity of solder joints.

Therefore, solder is not necessarily a bad conductor, but proper technique must be used to ensure efficient connections. With the right materials and techniques, it can create reliable electrical connections between components.

Is There Non-conductive Solder?

Yes, there is non-conductive solder. It’s typically used for applications that require electrical insulation and is made of materials such as ceramic or glass. Non-conductive solder can also be made from specialized metal alloys that are designed to reduce the risk of short circuits. While non-conductive solder has its uses, it does not have the same level of conductivity as regular metallic solder. This means it may not be suitable for certain applications where a strong electrical connection is needed. [2]

Despite these limitations, non-conductive solder still has its place in many projects where using an insulated material is beneficial. Whether you choose to use regular conductive metallic solder or a specially designed non-conductive soldering material should depend on the requirements of the project. It’s important to carefully consider all factors when selecting a solder for the job at hand.

Is Solder As Conductive As Copper?

Solder is often used in electrical connections, but it’s not as conductive as copper. Solder has a very low electrical resistance compared to other metals, so it can be used to connect two or more components with only a small effect on the overall current flow. However, solder is not nearly as good of an electrical conductor as copper and does not usually provide a high level of efficiency when transferring electricity from one component to another. Copper is much better at conducting electricity than solder and provides a much higher degree of efficiency for your electronics projects. Therefore, it is generally recommended that copper wires be used whenever possible when making electrical connections instead of soldering them together.

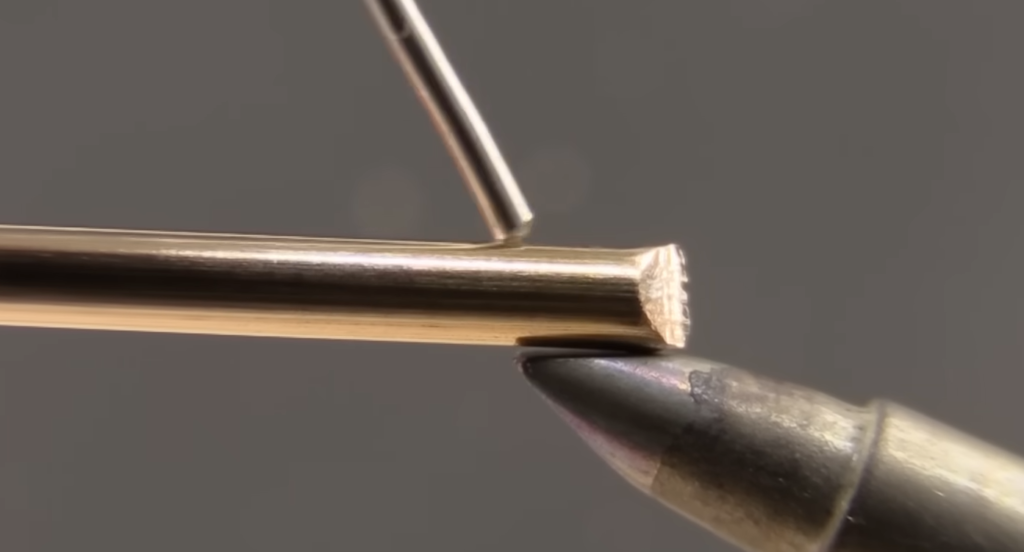

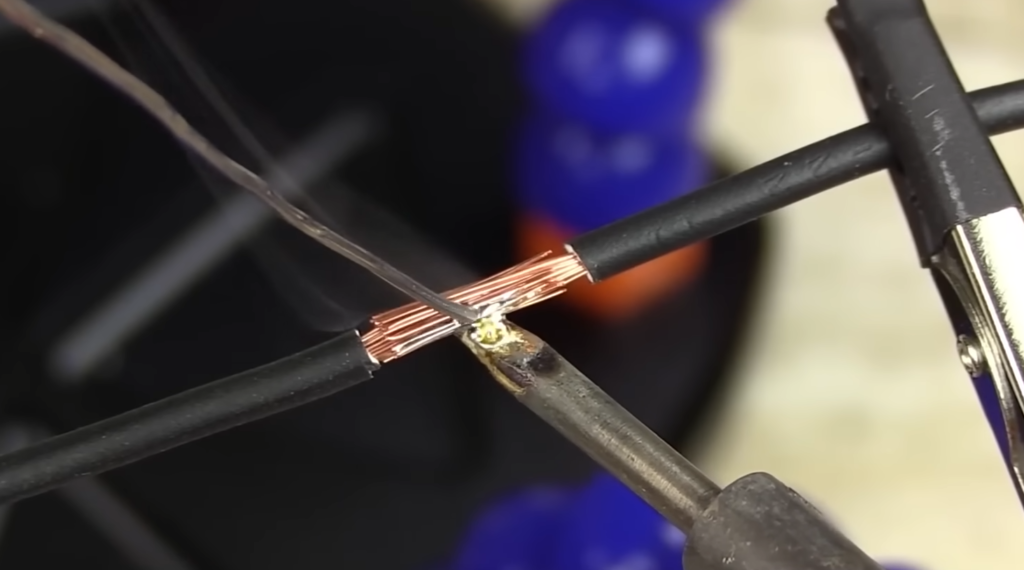

Can I Solder Without Flux?

Soldering requires heat and a material that will melt when heated, such as solder. It also requires a conductive surface in order for the solder to flow onto it. This is where flux comes into play: flux helps to ensure a proper connection between the two surfaces by creating an oxidation-resistant layer on the metal’s surface. Without using flux, there is a greater risk of your soldering job failing since oxides form quickly and could act as insulators. As such, it is highly advised not to attempt soldering without using flux. Furthermore, some metals are more difficult to work with than others and require even more care – these include lead-free materials and copper alloys that contain zinc or tin. In this case, flux is even more necessary to ensure that the solder bonds well to the surface.

When soldering, it’s important to always use flux in order to ensure a strong and reliable connection. Flux also helps to minimize oxidation of the surfaces which can lead to poor connections or failed joints over time. In conclusion, although it is possible to solder without flux, it is not recommended as it increases the risk of errors and could result in sub-par results. Using flux will help you get better results from your soldering job every time! [3]

What Is The Strongest Solder?

The strongest solder is a silver-based solder, made with either pure silver or an alloy of silver and other metals. Silver-based solder has the highest melting point, making it stronger than other types of solders. It also has excellent conductivity properties, which makes it better suited for more challenging electrical connections. Because of its strength and cost savings over traditional tin-based solders, silver-based soldering is often used in home electronics projects as well as commercial and industrial applications. While this type of solder is useful in many settings, it does require special techniques to use properly. Professional assistance may be necessary if you are not experienced in working with this type of material.

Does Liquid Solder Conduct Electricity?

Liquid solder is a type of metal alloy that is melted down and used to join two pieces of metal together. It consists of an alloy made up mostly of lead, tin, and usually also has some other trace elements like silver or copper. When it cools down it forms a strong bond between the two metals.

The answer to the question whether liquid solder is conductive depends on the composition of the soldering material used. Generally speaking, most types of liquid solder contain an electrical conductor such as lead or copper, which makes them conductive when heated up and cooled down again. Depending on its composition, liquid solder may have different levels of electrical resistance which will affect its ability to transmit electricity. As a rule of thumb, higher quality liquid solders will be more conductive. [4]

When it comes to electrical safety, the use of liquid solder is not recommended for applications which require a high degree of electrical insulation, such as with wiring in walls or appliances. This is because liquid solder can potentially cause short circuits due to its conductive properties and should only be used where absolutely necessary.

To sum up, liquid solder is generally considered to be an effective conductor of electricity when heated up and cooled down again. However, for safety reasons it should only be used when strictly necessary and not for applications which require a high level of electrical insulation.

Can I Use Superglue Instead Of Solder?

No, it is not recommended that you use superglue instead of solder if you are trying to make an electrical connection. Even though solder is a metal and is therefore a conductor of electricity, superglue does not possess the same conductive properties. Superglue can be used to secure other components in place but should not be used as a replacement for soldering when making an electrical connection. Additionally, the chemicals in superglue may corrode or damage sensitive electronic components. Therefore, solder should always be used to create any electrical connections needed on your project or circuit board.

How Long Does 100g Solder Last?

The amount of time a 100g solder lasts depends on how often it is used and the conditions in which it is stored. Generally, solders can last up to 10 years if stored properly in a cool, dry environment. The lifespan of solder can be further extended with proper maintenance such as cleaning flux residue from the joints and periodically replacing seals that are broken or worn out. Solder is an excellent conductor of electricity so it can last for many years if kept in good condition. Furthermore, using lead-free solder will also help prolong its life since lead-free solders have copper components that do not corrode as quickly as other materials. In short, with proper care and maintenance, a 100g solder should be able to last you many years. [5]

Can You Use Expired Solder?

No, you should not use expired solder. Solder is a metal alloy made up of lead and tin (or other metals) that melts at low temperatures. Over time, the composition of the solder changes due to corrosion and oxidation which reduces its ability to form strong bonds. Expired solder typically has a lower melting point than new solder and thus may not be suitable for certain applications. Additionally, it can become contaminated with impurities over time which can damage the components being soldered together. It’s best to always use fresh solder when joining two pieces of metal or electronics together in order to ensure that the connection holds securely during current flow and temperature fluctuations.

If you have any doubts about whether or not your solder is still good to use, it’s best to discard it and purchase a new batch of solder. Not only will this ensure that your connections remain secure but it can also help you avoid damaging expensive electronic components or risking your safety. Solder is an essential component for anyone working with electronics so it’s important to never take shortcuts in order to save money.

In summary, expired solder should not be used as its composition has changed over time which reduces its effectiveness. Additionally, the presence of impurities may damage the components being joined together. It’s best to always use fresh solder when joining metals or electronics in order to guarantee reliable connections and avoid potential damage or danger.

FAQ

Will electricity go through solder?

Yes, solder is a type of metal alloy and has conductive properties. It can be used to join two electrical components together or as part of an electric circuit. When heated with a soldering iron, the molten solder forms a bridge that allows electricity to flow through it. However, the amount of current that goes through the joint depends on the size and shape of the solder joint and different types of solder have differing levels of conductivity. Therefore, for maximum performance, it is important to select the right type and size of solder for any given application. In addition, proper technique must also be utilized in order for a good connection to be made between two electrical components.

Are all metals conductive?

No, not all metals are conductive. Metals that are not conductive are referred to as non-conductive or insulating metals, and they include materials like rubber, plastic, and glass. Non-conductive metals cannot be used in electrical applications as they will not allow electricity to pass through them. Thus, it is important to select the right type of metal when using solder in an electrical application.

Can I use solder on aluminum?

Yes, you can use solder on aluminum. However, because aluminum is a softer material than other metals such as copper and brass, it may require additional preparation before soldering. This includes cleaning the surface of the aluminum with a light abrasive before applying flux and heating the joint evenly with a soldering iron to ensure a strong connection. It is also important to select the correct type of solder for aluminum, as some alloys are not compatible with the material and may cause damage or electrical failure.

Is solder as conductive as wire?

This question is a tricky one, as solder does not conduct electricity in the same manner as wire. While solder cannot replace wires completely, it can improve the electrical connection between two components. Solder is used to create a “joint” between two metals, which helps to reduce resistance and provide a more reliable connection than other alternatives. Some types of solder are even considered to be better than wires when it comes to heat dissipation and electrical losses due to their higher melting point.

Is it safe to solder a live wire?

No, it is not safe to solder a live wire. Soldering can be dangerous as the metals involved can become extremely hot and could produce sparks which could ignite flammable materials nearby. Additionally, if you were to come into contact with the live wire while soldering, you could receive an electric shock. It is important that any wires being soldered are turned off and unplugged from the power source before beginning in order to avoid any safety risks or damage to components.

How much power can a solder hold?

Solder is an alloy of lead and tin that can hold up to 10 amps of current per square inch, making it effective for most electrical applications. However, its strength is dependent on how thin the solder is and the quality of the connection. If too much current passes through a soldered joint for a prolonged period of time, then the metal may become heated and eventually break or melt away from the connection, causing failure. Therefore it’s important to choose a solder with appropriate thickness and quality for the job at hand. Additionally, some types of solder are designed to handle higher levels of heat or provide better thermal conductivity than others. The right choice will depend on your specific application. In general though, most regular applications require no more than 10 amps of current per square inch to be handled by the solder. It’s important to remember that even though solder is highly conductive, it should never be used in place of wiring or other components for high power applications.

Useful Video: 10 STUPID ERRORS To AVOID in Soldering and TIPS

Conclusion

Yes, solder is a great conductor of electricity. It is used in many different electronics and electrical components due to its ability to bond two pieces together as well as provide a reliable conduit for current flow. Solder also has the added benefit of being very resistant to oxidation so it will maintain its conductivity for many years with minimal maintenance. So whether you’re joining wires or circuits, soldering is an excellent choice for making sure your connections are reliable and safe.

References

- https://www.nature.com/articles/150371b0

- https://www.circuitsgallery.com/is-solder-conductive/

- https://fixitmanblog.com/does-solder-conduct-electricity/

- https://rpsautomation.com/lead-vs-lead-free-solder-conductivity/

- https://weldingmastermind.com/is-solder-flux-conductive-heres-the-truth/

Leave a Reply