Are you confused by the differences between UL 891 and UL 1558 Switchboard? Understanding these two codes is important if you are in the market for a switchboard, so it’s essential to know which one will best suit your needs. In this blog post, we’ll break down both UL 891 vs. UL 1558 Switchboard codes and explain why each may be a better option depending on your specific circumstances. Armed with all the information necessary, you can make an informed decision that gives you peace of mind knowing that your switchboard meets code requirements.

Definition and Glimpse of UL 1558

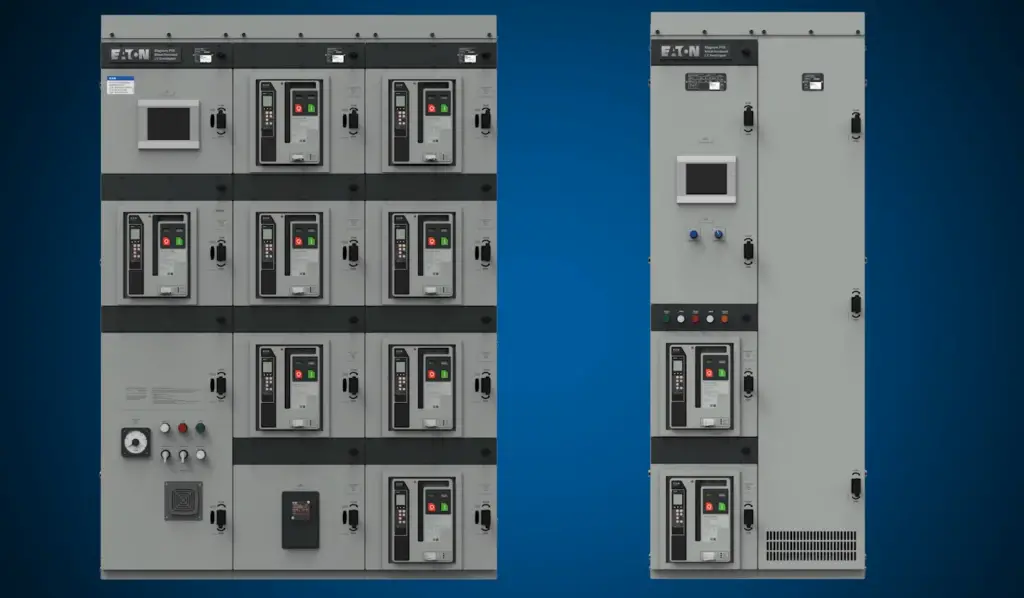

UL 1558 Switchboard is one of the standards created and maintained by the UL organization for low-voltage switchboards. Low-voltage switchboards are typically used in commercial buildings such as schools, factories, hospitals, and retail stores where larger amounts of power are needed than residential applications require.

These switches manage the flow of electricity from a main source into multiple circuits within the building. They are available in housing units ranging from 600 volts to 5000 volts with or without protection devices. To meet UL 1558 standards, these switchboards must have numerous features including an effective insulation system, labeling and marking panels, overcurrent protection, and built-in safety interlocks. [1]

UL 1558 switchboards are specially designed to withstand high electrical stresses that could cause a device to malfunction or even become dangerous. They also feature superior temperature control capabilities which helps prevent the circuit breakers from overheating. UL 1558 compliant switchboards are highly reliable, durable, and safe for use in commercial buildings with large loads of electricity needs. With these standards in place, businesses can rest assured that their switchboard is up to code and will continue running safely and efficiently for years to come.

Definition and Glimpse of UL 891

UL 891 is another set of standards created and maintained by UL for low-voltage switchboards. This type of switchboard is typically used in larger industrial applications such as power plants, substations, or steel mills where higher voltages are required. The UL 891 standard is intended for use in environments with a maximum system voltage up to 1000 volts and an ampere rating of 2000A or less.

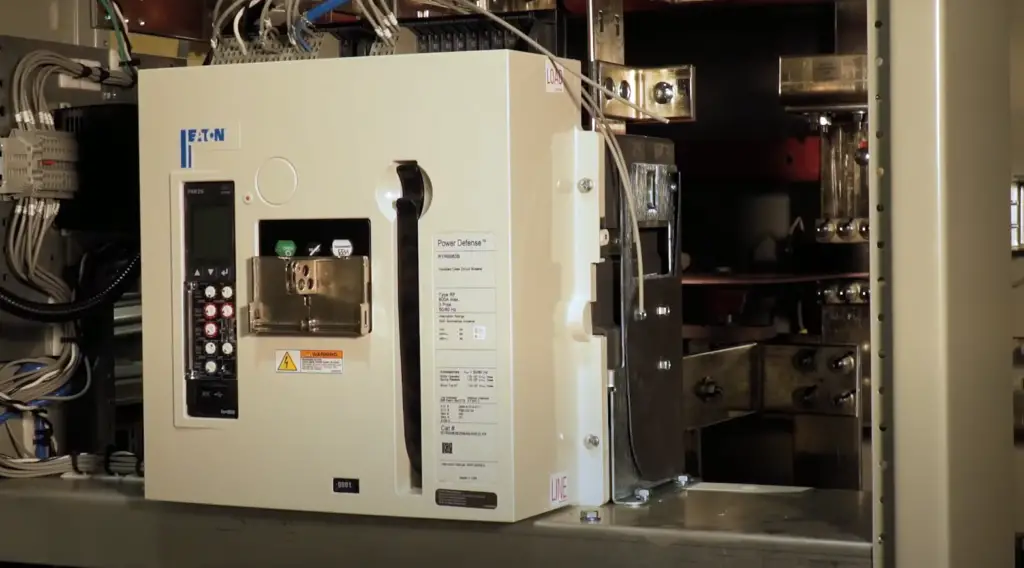

This type of switchboard must be designed and constructed to meet the rigorous requirements outlined in the UL 891 standards, which include provisions for physical protection, arc flash protection, fault-current interruption capacity, wiring methods, overcurrent protection devices, control components, and much more. In addition to providing safety measures for personnel operating the switchboard, these standards also require that all components used inside the switchboard meet certain performance criteria related to temperature rise, electrical insulation ratings, short-circuit current ratings (SCCR), and other applicable safety requirements. [2]

Overcurrent Protection And Draw-out Design

The UL 891 switchboards use fuses or circuit breakers with a maximum voltage rating of 600 volts to provide overcurrent protection. UL 1558 switchboard systems, on the other hand, use molded case circuit breakers in draw-out design to provide overcurrent protection. Draw-out designs allow users to easily remove and replace the circuit breaker from the switchboard, something that is more difficult with fuse based boards. This helps increase safety when making repairs or adjustments as the live parts of the board are isolated from personnel working on them. In addition, UL 1558 switchboards can include built-in ground fault monitoring for improved safety and diagnostic capabilities.

Ultimately, these differences make UL 1558 switchboards a better option than UL 891 when maximum safety requirements are needed. For industrial and other high-power applications, UL 1558 switchboard systems provide an easy to maintain solution with improved protection for personnel working on them.

Fault Current Ratings

When it comes to switchboards, UL 891 and UL 1558 have different requirements for fault current ratings. For UL 891 switchboards, the interrupting rating must be at least equal to the maximum available fault current of the system. On the other hand, UL 1558 switchboards require that their interrupting rating be no less than five times the maximum available fault current of the system. This difference is important as it provides a greater level of safety in case of system faults. In addition, UL 891 requires that all protective devices have an interrupting rating equal to or greater than its associated circuit-breaker used to open and close individual circuits. Whereas, UL 1558 does not require this same requirement as long as the overall protection scheme meets the requirements.

Short-time and Temperature Rise Rating

When comparing UL 891 vs. UL 1558 switchboards, it’s important to consider the short-time and temperature rise ratings in addition to the other safety considerations. The short-time rating is the amount of current that a switchboard can safely carry for 1 minute without damaging its components or causing hazardous conditions. It is an indication of the maximum level of overload protection available from the switchboard. The temperature rise rating is another measure of a switchboard’s safety, indicating how much heat will be generated when it carries its rated current load over extended periods of time. [3]

UL 891 switchboards are required to have a short-time rating greater than or equal to 60 seconds and a temperature rise rating greater than or equal to 140°C. UL 1558 switchboards, on the other hand, must have a short-time rating greater than or equal to 30 seconds and a temperature rise rating greater than or equal to 150°C.

The higher short-time and temperature ratings of UL 891 switchboards can provide an additional level of safety, but it is important to note that they also mean that these switchboards will be larger and more expensive than their UL 1558 counterparts. Additionally, it may be difficult to find UL 891 certified devices as they are less common in the market.

How UL 891 is Ahead of UL 1558?

The UL 891 standard is much more stringent than the UL 1558 standard. It requires switchboards to have a greater degree of fire-resistance, as well as improved protection against electrical shock and arc flashes. The cables used for UL 891 switchboards must also be insulated with flame-retardant material so that they won’t catch on fire if an electrical short occurs. As a result of these higher safety standards, UL 891 switchboards are considered safer than those built according to the UL 1558 standard.

UL 891 switchboard enclosures are usually made from stainless steel or other fireproof metals instead of plastic or wood used in many UL 1558 boards. Furthermore, the inside components are designed for immediate shut-off of electricity in the event of a short circuit or other emergency situation. The UL 891 switchboards also have additional safety features such as overload protection, special grounding systems, and low voltage alarms.

In addition to increased safety standards, UL 891 switchboards are designed for increased longevity compared to those built with the UL 1558 standard. This is because they have greater durability and can better withstand physical shocks and harsh weather conditions than their UL 1558 counterparts. Therefore, installing an industrial-grade switchboard made to meet the UL 891 standard means that you will be getting a high-quality product that will last for years without needing repairs or replacements. [4]

How UL 1558 Exceeds UL 891?

UL 1558 is a newer and more comprehensive safety standard than UL 891. It updates requirements from National Electrical Code (NEC) in several ways to ensure the safety of both personnel and equipment. The primary areas where UL 1558 exceeds UL 891 are its testing methods, design considerations, environmental performance standards, and operator interface criteria.

For testing methods, UL 1558 enforces higher levels of voltage withstand tests for the internal parts such as busbars, conductors, contactors, etc. It also requires additional durability tests such as endurance test cycles and temperature cycling tests. All these measures help increase the switchboard’s reliability and safety over time.

In terms of design considerations, UL 1558 requires switchboards to employ arc fault protection systems and restrict the usage of combustible materials. It also enforces a maximum operating temperature for both indoor and outdoor use, in addition to defining separate design criteria for each application. This is intended to ensure that the switchboard is suitable for its intended environment and won’t succumb to environmental factors such as moisture or dust.

Furthermore, UL 1558 sets stricter standards for operator interfaces by requiring higher levels of visibility and accessibility. For instance, it requires manual controls to be clearly labeled with their corresponding functions, while also specifying minimum size standards for both viewing windows and control panels. All these measures are designed to minimize user errors while ensuring switchboard operators can quickly assess situations and take appropriate actions if needed.

In short, UL 1558 is a more robust standard than UL 891 in almost every way. Its testing methods, design considerations, environmental performance standards, and operator interface criteria exceed the requirements of UL 891 and provide greater peace of mind for switchboard users. For these reasons, UL 1558 is often considered the preferred safety standard for industrial switchboards.

Pros and Cons of UL 1558

UL 1558 switchboards are a type of industrial panelboard designed for 600V and below. They provide reliable protection against electric shock and short circuits, making them an ideal choice for applications in commercial buildings, factories, laboratories, hospitals, and any other facility where safety is a priority. Some of the advantages of UL 1558 switchboards include:

- Higher current ratings – UL 1558 enables higher current ratings than UL 891 because it has better coordination with overcurrent protective devices. This makes it possible to use larger cables and equipment in the same space as compared to UL 891 switchboards.

- Better insulation – UL 1558 uses increased numbers of neutral conductors which improves its ability to limit the impact of short-circuits and surges.

- Increased flexibility – UL 1558 switchboards feature fewer components than UL 891, which means more space can be used for other equipment or controls. This makes it easier to configure the panelboard to meet specific needs and applications.

Despite these advantages, there are some downsides to using UL 1558 switchboards. They require larger conductor sizes in order to carry higher currents, which increases their cost and may limit the available options for certain applications. Additionally, due to their increased complexity, they often require a professional electrician or engineer with expertise in this area in order to properly install them. Finally, because of their additional safety features, they may not be suitable for all environments where a lower level of safety is acceptable.

Overall, UL 1558 switchboards offer an improved level of protection compared to UL 891 and can be a good choice for applications requiring higher current ratings and better insulation. However, it’s important to consider the added complexity and cost associated with using this type of panelboard before making a decision. [5]

Pros and Cons of UL 891

UL 891 is a standard for testing industrial control panels, such as switchboards. It’s widely accepted and provides companies with a great deal of flexibility when it comes to certifying their products.

UL 891 has the following advantages:

- UL 891 simplifies the process of product certification, making it easier and faster for companies to get their switchboards approved.

- The requirements laid out by UL 891 are more comprehensive than those set forth by other standards, which helps ensure that products meet stricter safety regulations.

- UL 891 allows for customization of products without compromising on quality or safety. This means that companies can tailor their switchboards to fit specific needs while still meeting the stringent standards set by UL.

On the other hand, there are also some drawbacks associated with UL 891. These include:

- The cost of certification can be higher than other standards, as UL 891 is more stringent and demanding.

- It requires a greater level of expertise to ensure that products meet the requirements of the standard. Companies must have sufficient knowledge of industrial control panels in order to comply with UL 891.

- In some cases, it may not be feasible for companies to certify their switchboards with UL 891 due to its high cost and complexity.

FAQ

What is the difference between UL 1558 and 891?

UL 891 is a safety standard for industrial control equipment, including switchboards and panelboards. UL 1558 is a safety standard specifically for switchboards used in commercial and industrial applications. While both standards cover various aspects of safety, UL 1558 also covers additional requirements such as fire hazard protection and arc-fault protection. What types of switchboards are covered by UL 891?UL 891 covers many different types of industrial control equipment that includes switchboards and panelboards. These include power distribution assemblies, motor controllers, transfer switches, combination starters, bus plugs and busway systems.

How often do I need to test my switchboard against UL 891 or 1558?

Testing is required whenever a new switchboard is installed or when an existing one undergoes significant modifications. Additionally, periodic inspections should be conducted at least once every three years or after major equipment repairs/replacements. It’s important to note that these inspections should be conducted by a qualified electrician.

What is UL 891 standard for switchboards?

UL 891 is a standard from Underwriters Laboratories (UL) that applies to factory-built, switchboard assemblies. It covers general requirements such as voltage ratings, short-circuit withstand ratings, types of enclosures and other special features. UL 891 regulates the construction of the switchboards to ensure safety and reliability. The standard requires these devices to also undergo extensive testing before they are authorized for use in commercial or industrial applications. Additionally, UL 891 mandates the installation and maintenance of listed components within the switchboard itself. This helps ensure safe operation in accordance with manufacturer’s instructions and local codes.

What is UL 891 switchgear?

It is most commonly used in industrial settings for managing high-voltage circuits and other related applications. The UL 891 standard was originally developed by Underwriters Laboratories (UL) to provide detailed safety requirements for such types of equipment. This type of switchgear is designed with an extra layer of protection against fault currents, thermal overloads, and other potentially hazardous conditions that can occur during operation. It also offers superior arc-fault containment capabilities when compared to traditional designs. In addition, it has been tested and rated at higher voltage levels than other assemblies on the market.

What is the difference between UL switchgear and switchboard?

UL 891 Switchgear is an equipment assembly that contains both switching and protective devices, usually used to control, protect and monitor circuits. UL 1558 Switchboard is a prefabricated enclosure containing various types of electrical equipment such as switches, circuit breakers, surge protectors and more. Switchgear is designed to provide protection for an individual piece of equipment or circuit within the switchboard system while providing the capability to switch individual loads or branches on/off or transfer load between sources quickly during emergency conditions. Switchboards are typically used in industrial applications where large amounts of current need to be distributed from a single source point throughout multiple branch circuits.

Conclusion

In conclusion, UL 891 and UL 1558 Switchboard have distinct requirements when it comes to switchboard construction. While they both offer safety and efficiency with the use of industrial control panels, their differences should be taken into account when selecting which type to install. UL 891 is designed for applications that need a high level of protection from corrosion, while UL 1558 Switchboard provides more cost-efficiency in terms of installation and maintenance. Both standards provide invaluable protection against potential risks associated with electric power distribution systems but depending on the specific application, either one may be more suitable. Ultimately, understanding the purpose and function of each standard can help ensure that businesses select the best option for their environment.

Useful Video: Low-voltage switchgear

References

- https://cdn2.hubspot.net/hubfs/4333126/Files/Technical%20Information/ASCO/White%20Papers/Power%20Control%20Systems/ASCO%20ul-standards-for-power-control-system-equipment.pdf

- https://www.circuitsgallery.com/ul-1558-versus-ul-891/

- https://forums.mikeholt.com/threads/ul1558-and-891.66587/

- https://www.slideshare.net/michaeljmack/891-switchboard-vs-1558-switchgear

- https://www.eng-tips.com/viewthread.cfm?qid=155576

Leave a Reply