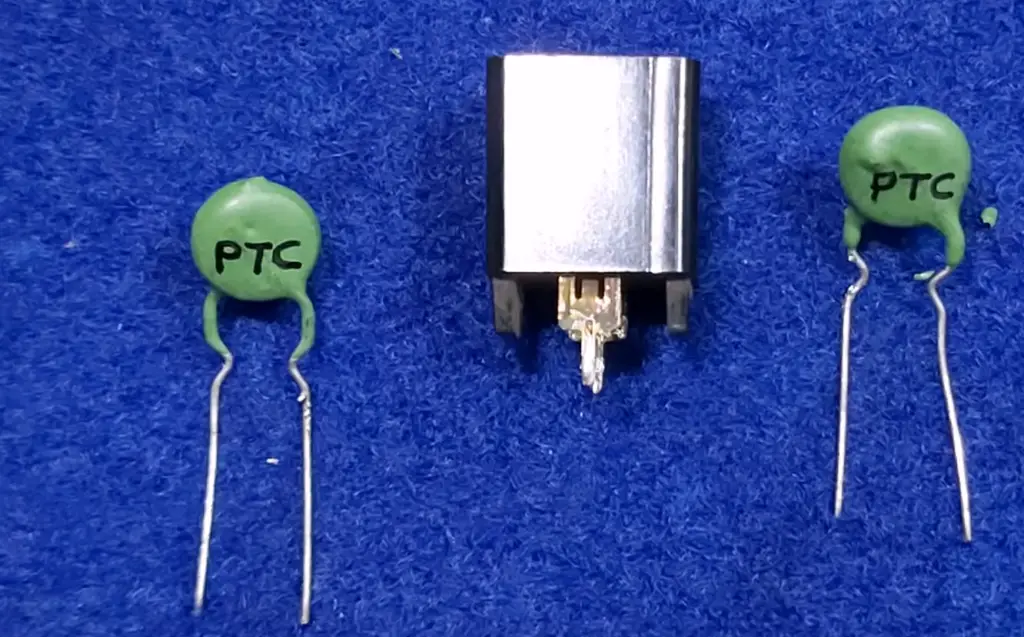

What is a PTC thermistor? This is a question that you have likely heard before, but may not know the answer to. A PTC thermistor is a type of resistor that can be used in a variety of applications, including temperature sensing and control. In this article, we will provide a full overview of what PTC thermistors are and how they work. We will also answer some common questions about these devices and provide some tips on how to use them effectively.

What is a PTC Thermistor

Unlike other temperature sensors, such as thermocouples and Resistance Temperature Detectors (RTDs), the resistance of a PTC thermistor will increase rather than decrease with increasing temperature. This property can be used in many applications, ranging from consumer electronics to industrial automation systems.

PTC thermistors are made up of a ceramic material that has been doped with small amounts of metal oxides, such as manganese oxide or cobalt oxide. When an electrical current flows through this material, the increased temperature causes its molecular structure to change, resulting in an increased resistance. As the temperature continues to rise, the resistance will continue to increase until it reaches its maximum value. This makes PTC thermistors ideal for sensing over-temperature conditions in a system.

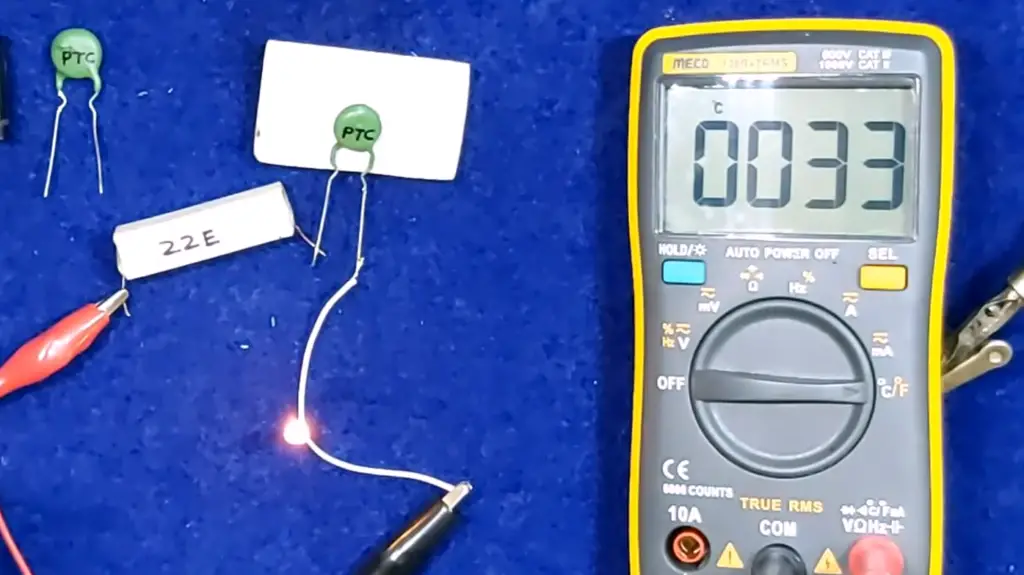

When used as a temperature sensor, PTC thermistors are typically connected in series with a resistor across an AC voltage source. When the temperature rises above a certain threshold, the increased resistance of the PTC thermistor causes more current to flow through the resistor instead of through itself. This in turn produces a signal that can be used to activate an alarm or other warning devices when appropriate temperatures are reached. [1], [2], [3]

Characteristics of PTC Thermistors

Now that you know what a PTC thermistor is, let’s discuss some of the characteristics that make them so useful in temperature sensing applications.

Transition temperature

The most important characteristic of a PTC thermistor is its transition temperature. This is the temperature at which the resistance of the device starts to increase rapidly, and it is usually set at the same level as an over-temperature alarm. The value of this temperature can be adjusted by changing either the material used to make the thermistor or by adjusting its doping levels.

PTC thermistors exhibit a slightly negative temperature coefficient until the point at which their resistance reaches its minimum. Above this point, its coefficient rises slightly until it reaches the transition temperature (TC).

Minimum resistance

This value is important for designing circuits that involve PTC thermistors, as it allows engineers to choose appropriate values for other components in the circuit.

Rated resistance

The rated resistance of a PTC thermistor is the amount of resistance it will typically have when exposed to room temperature. This value can range anywhere from tens of ohms to thousands of ohms, depending on the model and size. Accurate readings are guaranteed with the use of a low current, ensuring that thermistor does not experience any excessive heat which could skew results.

Dissipation constant

The dissipation constant is the connection between the power supplied and how much a body’s temperature rises from its own heat. The dissipation constant is affected by things like the material of the wires, how the thermistor is attached, temperature in your area, how heat moves around the device and its size and shape. The dissipation constant is an important factor that has an effect on the self-heating properties of the thermistor.

Maximum rated current

When dealing with PTC thermistors, one of the most important terms to understand is maximum rated current. Maximum rated current is the electrical current that a PTC thermistor can handle without failing or affecting its performance at specified ambient conditions. As a result, it’s important to select the right PTC thermistor for your application as too much current could cause permanent damage and failure.

The maximum rated current depends on several factors including dissipation constant and the R-T curve of the thermistor. The higher the dissipation constant, the lower the maximum rated current becomes. It’s also important to note that a PTC thermistor’s R-T curve can shift over time and as a result, its performance may not remain consistent with time.

Maximum rated voltage

When using a PTC thermistor at its maximum rated voltage, it is important to monitor its temperature and current draw to ensure safe and reliable operation. Properly designed circuits should incorporate protective components such as circuit breakers or fuses in order to prevent excessive current draw due to an over-voltage condition.

Additionally, when powering multiple devices with a single power source, it is important to ensure that the total current draw does not exceed the maximum allowable for each individual device. Just like maximum rated current, maximum rated voltage depends on several factors including dissipation constant and the R-T curve of the thermistor.

It is important to note that when voltages applied to a PTC thermistor exceed their maximum ratings, they may develop excessive heat or even short circuit, leading to potential damage or failure of other components in the circuit. Therefore, care must be taken when selecting an appropriate voltage rating for a particular application. [1]

Modes of Operation

PTC thermistors also have different modes of operation, which determines their response to the environment they are placed in. Let’s discuss those.

Self-heated mode

The self-heated mode is the simplest to understand. It works on the principle of Joule heating – when a current passes through the PTC thermistor, it produces heat which causes its resistance to increase. This is because a higher temperature increases the number of charge carriers and changes their mobility, leading to an increased resistivity.

In this mode, there is no need for external heating elements or power sources; as long as enough current passes through it, the PTC thermistor will produce its own thermal energy.

If the electricity stays the same, the amount of electricity will stay steady when the thermistor is not getting hotter or colder. The temperature stays the same if we apply a certain voltage and know how much heat is lost. This way of working is often used when making circuits that depend on how hot or cold it is and also how long something should take.

Sensing mode

Another mode of operation for a PTC thermistor is sensing. When operated in this manner, the thermistor’s power consumption is so meager that it has a trivial influence on its temperature and – consequently – resistance, which starkly contrasts with the self-heated mode. When measuring temperature, the R-T curve is used as a guide. This is called sensing mode. [2]

Typical Applications for PTC Thermistors

Now that you know about the different characteristics of a PTC thermistor, you may be wondering what it can be used for. There are endless possibilities! Let’s discuss some of the most common.

Self-regulating heaters

PTC thermistors can be used to make self-regulating heaters. They are often found in car seat warmers, electric blankets, and space heaters. When the temperature reaches a certain point, the PTC thermistor will stop conducting current, thereby preventing the appliance from overheating. This makes them an ideal choice for safety applications where reliability is key.

Circuit protection

The ability of a PTC thermistor to limit current can also be beneficial in circuit protection applications. As the temperature rises due to an overload or short circuit, it allows the device to cut off power before serious damage occurs. This can help protect sensitive components and extend the life of your electronics.

PTC thermistors can also be used to protect DC motors from damage due to excessive current. In a motor control circuit, the PTC thermistor will limit the amount of current going into the motor, preventing overheating and potential burnout. This is especially important for motors that are constantly running at high speeds, such as those found in industrial equipment.

Solenoid valves are another common application for PTC thermistors. They can be used to protect the valve from high current surges, allowing them to operate reliably and safely.

Sensing liquid levels

PTC thermistors are commonly used in sensing liquid level applications. This is due to their high accuracy and stability, as well as the fact that they can be safely submerged in water. They are often embedded into a float-style device which allows them to detect changes in the liquid level. This type of monitoring system is especially useful for controlling pumps and other liquids flow systems.

Measurement & control of temperature

PTC thermistors are commonly used in temperature measurementand control. This means they can sense changes in temperature and then act accordingly to regulate it, such as turning on or off a heater or cooling system. For example, if the temperature rises above a certain level, the PTC thermistor will detect the change and shut off the system. This is why you often find them placed near heat-generating electronics like computers and amplifiers – to keep them from overheating.

Industrial inverters

Industrial inverters are one of the most important applications for PTC thermistors. They’re often used in electric motors, transformers, and other high-power electrical equipment. The thermistor helps to protect the system from surges and over-temperature events. As temperatures increase, the PTC thermistor’s resistance value increases as well, preventing too much current from running through the system and ultimately protecting it from damage.

As a thermal switch

Lastly, PTC thermistors are commonly used as thermal switches. A thermal switch consists of a thermistor that is wired in series with a circuit and a resistor. As the temperature increases, the resistance of the PTC thermistor increases greatly which reduces the current flowing through both components. This means that when an over-temperature situation occurs, the current flow drops off and a safety shutdown can occur.

This makes them ideal for use in applications such as HVAC systems where it’s important to shut down the system if it gets too hot or too cold. [2], [3]

FAQ

What are the advantages and disadvantages of a PTC thermistor?

PTC thermistors have a number of distinct advantages when compared to other temperature detection technologies, including their fast response time, linearity and wide temperature range. Additionally, they are relatively inexpensive to manufacture and require minimal additional components for operation. Furthermore, PTC thermistors can be designed with operating characteristics that make them suitable for use in a variety of applications.

The primary disadvantage associated with PTC thermistors is their poor interchangeability and non-linearity of thermoelectric characteristics. This can lead to considerable variations in their performance from device to device, resulting in a need for careful selection and testing of individual components when used in applications requiring extremely precise temperature readings.

What are PTC sensors used for?

PTC thermistors are used for a variety of temperature sensing applications. They can be used to detect excessive temperatures, regulate the temperature of appliances, and power supplies as well as provide thermal protection in industrial equipment.

But most importantly, PTC thermistors are used in some of the most advanced and sensitive temperature control systems such as medical equipment, automotive electronics and telecommunications.

What material is a PTC thermistor?

PTC thermistor is made of a material known as doped polycrystalline ceramic. It is made from a combination of barium titanate and other materials, such as lead or cobalt, which have been pre-doped with electrical charges. When exposed to heat, the material undergoes a significant increase in its resistance (a positive temperature coefficient). This means that the current flowing through it decreases when it gets hotter – thus making it an effective thermal protection device.

What is the difference between NTC and PTC-type thermistors?

This means that as the temperature increases, their electrical resistance decreases. NTC thermistors are commonly used in many industries for applications such as temperature sensing and control.

PTC (Positive Temperature Coefficient) thermistors, on the other hand, have a positive electrical resistance-temperature coefficient. This means that as the temperature increases, their electrical resistance also increases. PTC thermistors are commonly used for applications where overheat protection is required such as motor starters and other thermal overload protection devices. They can also be used to detect fluid flow or to measure air velocity in HVAC systems.

What is an example of a PTC thermistor?

Generally, the element is made of two conductive plates held together by an insulating material called a dielectric. When the temperature rises above a certain threshold, the resistance of the material changes drastically, limiting current flow and thus changing its electrical characteristics. Examples of PTC thermistors include those used in automotive engine cooling systems, air conditioners, refrigerators and other applications where precise temperature control is required.

What is the difference between PT100 and PTC?

A PTC thermistor and a PT100 are two types of thermistors, which are temperature-sensing devices. Both measure changes in resistance that correspond to different temperatures, but the differences between them can be significant.

The most notable difference between PT100 and PTC is the measurement range. A PT100 has a range from -200°C to +850°C, while a PTC thermistor’s range is limited to between -40°C and +125°C. This makes the PT100 more suitable for higher temperature applications such as industrial processes or high power electronics like engines and steam turbines, while the PTC thermistor typically works best with lower temperature applications such as consumer electronics or HVAC systems.

Another difference between the two is their technology and sensitivity. The PT100 uses a two-wire resistance measurement technique that requires more power to measure accurate temperatures and typically has greater accuracy than PTC thermistors. On the other hand, PTC thermistors use one-wire current sensing, which is much more energy efficient and can measure temperature changes with remarkable accuracy up to 0.01°C when paired with appropriate electronics. This makes it ideal for low power applications like medical devices or automotive sensors where precision measurement is critical.

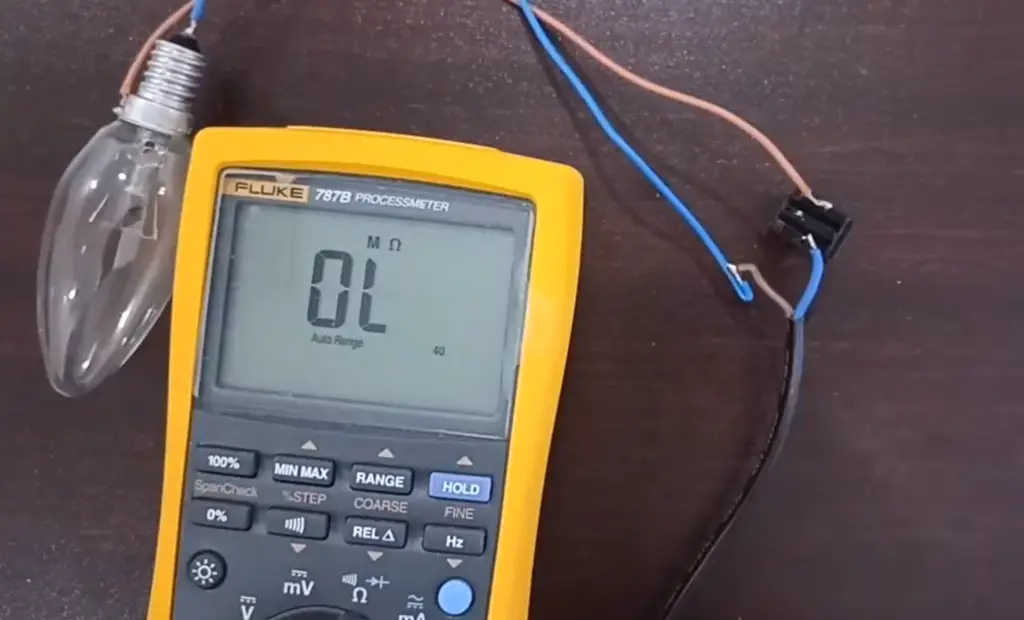

How can you tell if a thermistor is NTC or PTC?

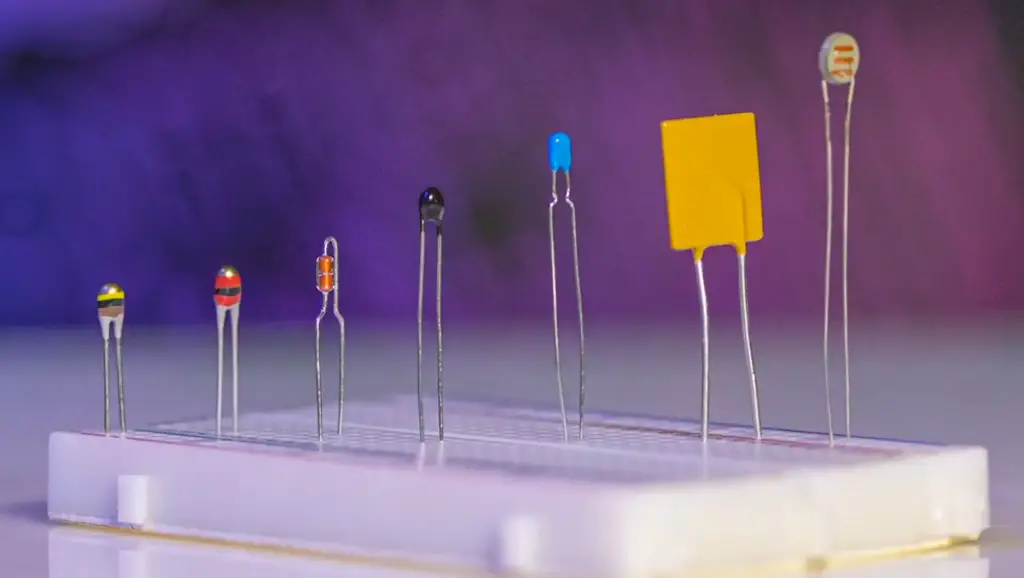

The easiest way to tell if a thermistor is NTC (Negative Temperature Coefficient) or PTC (Positive Temperature Coefficient) is by measuring its resistance at different temperatures. An NTC thermistor will have a decreasing resistance as the temperature increases, while a PTC thermistor will have an increasing resistance. It is also possible to differentiate between NTC and PTC thermistors based on their shape and size – NTCs tend to be smaller than PTCs, while NTCs are usually cylindrical or disk-shaped, whereas PTCs are often rectangular or square.

Useful Video: Thermistor Basics – NTC PTC

Conclusion

PTC thermistors are an invaluable tool for sensing temperatures in various applications due to their unique characteristics such as transition temperature, minimum resistance, rated resistance, dissipation constant and response time. They are highly accurate and versatile, making them a great option for temperature sensing in various industries.

In this article, we provided a comprehensive overview of what PTC thermistors are and how they work. We also discussed the different types available, along with tips on how to choose the right one for your needs.

We also provided you with a detailed description of characteristics of PTC thermistors, such as transition temperature, minimum resistance, rated resistance, dissipation constant and response time.

No matter the application you need to sense temperature in, there will likely be a PTC thermistor available to do it effectively. With that being said, if you have any additional questions about what is a PTC Thermistor or need further assistance selecting the right one for your application don’t hesitate to reach out to an expert.

We hope this Epic Guide has been helpful in providing you with all the information you need about PTC thermistors! Good luck and thank you for reading.

References

- https://eepower.com/resistor-guide/resistor-types/ptc-thermistor/#

- https://www.elprocus.com/ptc-thermistor/

- https://product.tdk.com/en/techlibrary/applicationnote/howto_ptc-limiter.html

Leave a Reply