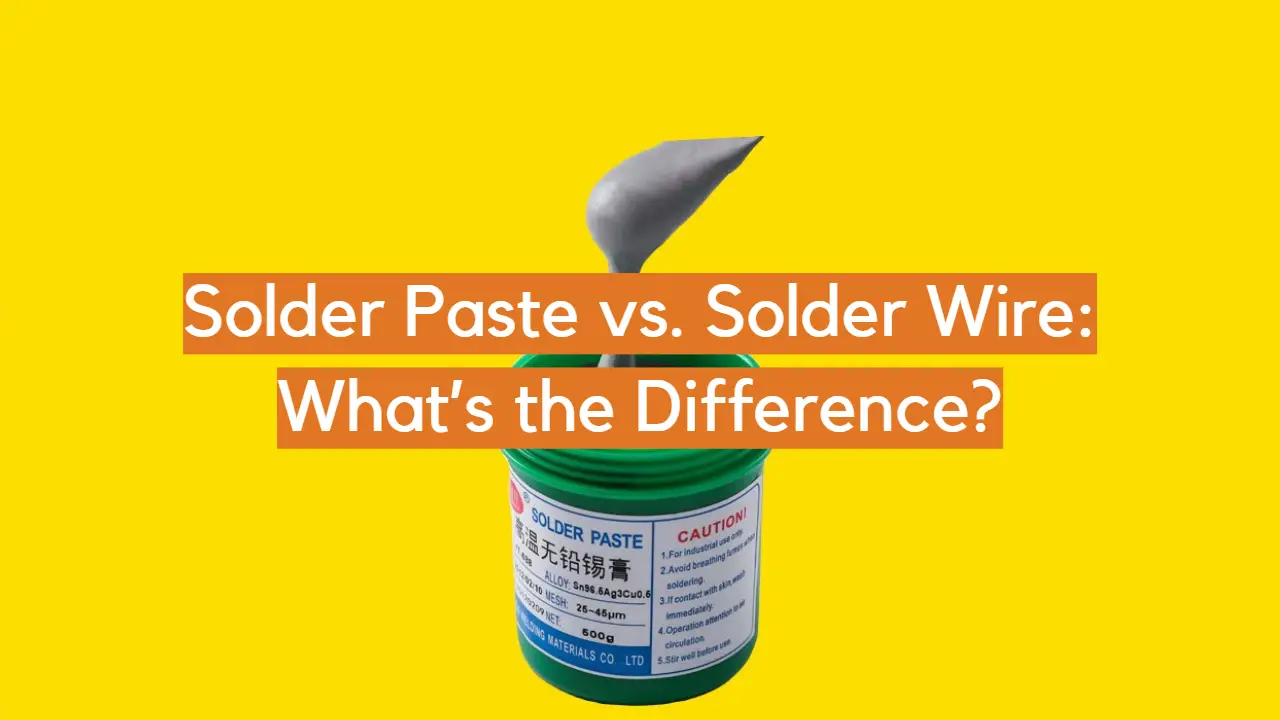

Do you know the difference between solder paste and solder wire? If not, don’t worry – you’re not alone. Many people don’t know the difference, and even experts can sometimes get them confused.

In this article, we will discuss the differences between solder paste and solder wire, as well as when each should be used. We will also provide some tips to help you choose the right type of solder for your project.

What Is Solder Paste?

Solder paste is heated, and the solder melts, connecting the two metal surfaces together. Solder paste is available in different types depending on the type of solder being used. It comes in syringes or in jars.

How Do You Use It?

Solder paste is typically used for surface mount technology (SMT) projects. It can also be used in through-hole applications, but is not suitable for all types of connections.

Before applying the solder paste to a circuit board, it must be heated to a specific temperature. The temperature and time required depends on the type of solder being used.

Additionally, the solder paste must be carefully applied to the component leads so that it is evenly distributed. [1]

How to Use Silver Solder Paste Syringes?

Silver solder paste syringes are an essential tool in many SMT applications. First, choose the right solder for your project. Then, attach the syringe to a power source and heat it until it reaches the desired temperature.

Carefully dispense the solder paste onto each component lead, making sure to evenly coat the leads. Finally, place the circuit board in a reflow oven and heat it until the solder melts and creates a strong connection.

How to Solder with Solder Paste?

Solder paste is an important tool in many SMT projects. First, choose the right solder for your project. Then, heat the solder paste to its melting point and apply it evenly to each component lead. Place the circuit board in a reflow oven, and then heat until all of the solder melts and creates strong connections between components on the board.

What Are the Advantages of Solder Paste?

Solder paste is a versatile tool that can be used in both SMT and through-hole applications. Additionally, solder paste can be heated to high temperatures without degrading, allowing for strong connections between components.

Solder paste also makes it easy to apply small amounts of solder evenly on components leads, which improves the quality and reliability of the connection.

What Is Solder Wire?

With solder wire, heat is applied directly to the surface being soldered with an iron or other heating device. The solder melts, forming a strong connection when cooled.

How Do You Use It?

Solder wire is often used to create a connection between a component and a circuit board. The solder wire is heated until it is melted and then carefully applied to the component leads. Once the solder has cooled, the connection will be strong.

Solder Paste vs. Solder Wire: What’s the Difference?

The main difference between solder paste and solder wire is the way they are applied. Solder paste is heated and then put on the component leads. Solder wire needs to be in contact with a heating device before it can be used.

Additionally, solder paste is often used for SMT projects, while solder wire is more suitable for through-hole applications.

When it comes to advantages, solder paste offers improved reliability and quality over solder wire.

Additionally, solder paste is easier to apply evenly on component leads. However, solder wire does have some advantages of its own, such as being able to withstand higher temperatures without degrading.

Overall, both solder paste and solder wire have their own benefits and drawbacks depending on the application. It is important to carefully consider which type of solder is best suited for the project before making a choice.

What Do You Need?

In order to use solder paste or solder wire, you will need a few things. You will need a soldering iron and/or a syringe to apply the solder paste; flux to help the solder flow over the component leads; and an appropriate type of solder that is suited for your project.

Additionally, it is always a good idea to have a few extra tools on hand in case you make a mistake, such as tweezers and a desoldering braid.

By having a good understanding of the differences between solder paste and solder wire, you can make an informed decision about which one is best for your project. Whether you choose to use solder paste or solder wire, it is essential to have all the necessary tools on hand in order to ensure a successful outcome.

With the right knowledge and materials, you can make connections that are reliable and of high quality.

How to Make the Right Choice?

Choosing between solder paste and solder wire ultimately comes down to the type of project you are working on. If you are dealing with SMT components or have limited space, then solder paste would be ideal. However, if you need a strong connection that can withstand high temperatures, then solder wire is the better option.

It’s also important to note that both types of solder require flux and a suitable soldering iron or heating device. Additionally, it is always recommended to have extra tools on hand in case you make any mistakes during the application process.

FAQ

What is solder paste vs wire?

Solder paste and solder wire are two different types of solders used for joining components. Solder paste is melted with a heating device and then applied to the component leads, while solder wire is heated directly on the surface being soldered.

Which is better, solder paste or wire?

The choice of solder ultimately depends on the project you are working on. Solder paste is good for small, space-limited projects, while solder wire is better for projects that need a strong connection that can withstand high temperatures.

What tools do I need to use solder paste or wire?

In order to use solder paste or wire, you will need a soldering iron and/or syringe. You will also need flux to help the solder flow over the component leads, and an appropriate type of solder that is suitable for your project.

Additionally, it is always recommended to have a few extra tools on hand in case you make a mistake, such as tweezers and a desoldering braid.

Which type of solder should I use?

It depends on the type of project you are working on. Solder paste is often used for SMT projects, while solder wire is more suitable for through-hole applications. Additionally, solder wire can handle higher temperatures than solder paste.

It is important to carefully consider which type of solder is best suited for the project before making a choice.

Do I need extra tools?

Yes, it is always a good idea to have some extra tools on hand in case you make any mistakes. This includes tweezers, flux, and a desoldering braid. Additionally, you will need a soldering iron or heating device depending on which type of solder you are using.

What’s the best way to ensure a successful outcome?

To ensure a successful outcome, it is important to have all the necessary tools on hand. Additionally, it is recommended to use flux and an appropriate type of solder that is suited for your project.

What precautions should I take when using solder paste or wire?

When working with solder paste or wire, it is important to take the proper safety precautions. This includes wearing protective eye gear, gloves, and a face mask to prevent inhaling hazardous fumes.

Additionally, it is recommended to keep all soldering tools away from combustible surfaces in order to avoid any potential accidents.

What are some advantages of using solder paste vs wire?

Solder paste offers improved reliability and quality over solder wire, as well as being easier to apply evenly on component leads. On the other hand, solder wire offers greater temperature resistance and durability.

Ultimately, it comes down to the type of project you are working on and which material is more suitable for that application.

Is solder paste the same as solder?

No, solder paste and solder wire are two different types of solders used for joining components. Solder paste is melted with a heating device and then applied to the component leads, while solder wire is heated directly on the surface being soldered.

It is important to understand the differences between them in order to make an informed decision about which type of solder is best for your project.

Is solder paste reusable?

No, solder paste is not typically reusable. It can be used only once before needing to be replaced. When using solder paste, it is important to take precautions as it contains hazardous materials and is flammable. Additionally, it should never be reused as the connections may not be reliable.

Can you use solder paste on wires?

Yes, solder paste can be used on wires, but it is not recommended. Solder paste does not provide the same level of reliability and durability as solder wire, so if you need a stronger connection then solder wire would be the better choice for this type of application.

Is soldering flux the same as soldering paste?

No, flux and solder paste are not the same. Solder paste is a type of solder made up of metal particles suspended in an organic vehicle. Flux is a chemical cleaner that helps to eliminate oxidation on the surfaces being soldered.

It is often used when applying solder paste or solder wire. Flux is not necessary for every soldering job, but it can be beneficial when working with difficult metals or components.

What are the post-soldering steps?

After soldering, it is important to clean off any excess solder or flux residue. This can be done with an appropriate cleaning solution and a soft cloth. Additionally, you should inspect the connections for any signs of weakness or damage. Lastly, you may want to test the connection by powering up your project and ensuring that it is functioning properly.

What other tips do you have for soldering with paste or wire?

When working with solder paste or wire, it is important to ensure that the surface being soldered is clean and free of any debris. This can be done by using flux and a soft cloth to wipe away any residue before applying the solder.

Additionally, make sure to use an appropriate soldering iron and use the correct temperature to ensure that the solder melts properly. Finally, when working with solder wire, it is important to use a helping hand tool to keep the components in place while soldering.

Which type of solder is the most beginner-friendly?

Solder wire is generally considered to be the most beginner-friendly type of solder. It offers greater temperature resistance and durability, and it can be applied directly on the surface being soldered without needing any additional materials like flux or paste.

Additionally, it can be used with a helping hand tool to keep components in place while soldering. For these reasons, solder wire is often the preferred choice for beginner projects.

Useful Video: What Type of Solder Should you use.

Conclusion

Solder paste is easier to use and can create a more reliable connection. However, solder wire can be a good option if you need to make a small repair or are working with limited supplies.

Regardless of which type of solder you choose, always take care when heating it up and be sure to follow the safety instructions closely. With the right tools and knowledge, you can ensure a successful soldering job. Thanks for reading!

References

- https://www.cooksongold.com/blog/learn/what-is-solder-paste-and-how-do-you-use-it/

Leave a Reply