Soldering stations are a great way to get started in the world of soldering. They allow you to have a consistent heat source that is easy to control. This makes soldering much easier and can help you avoid damaging your components. They are used in electrical and electronic assemblies and repairs.

There are many different soldering stations on the market, but two of the most popular ones are Hakko and Weller. Both of these brands make high-quality soldering stations that are used by professionals all over the world. So, which one is better? In this article, we will compare these two brands and help you decide which one is better for your needs.

What is the Difference Between Various Soldering Appliances

Before anything else, it is important to know that there are three main types of soldering appliances. In electronics, soldering is the process of joining two or more pieces of metal together by melting and flowing a filler metal (solder) onto the joint. The filler metal has a lower melting point than the workpieces being joined, so it can be melted without damaging them.

Soldering is distinguished from brazing in that the temperatures used and the metals involved are different. In addition, solder typically has a much lower tensile strength than the materials being joined.

For these reasons, soldering is commonly used to join electrical components to printed circuit boards (PCBs), as well as joining lead wires to electronic devices such as potentiometers and capacitors. It can also be used for joining metals such as copper, brass, and aluminum.

There are two main types of soldering: soft soldering and hard soldering. Soft soldering is used for electrical work and is typically done at lower temperatures. Hard soldering, on the other hand, is used for joining metals such as copper pipes and is done at higher temperatures. [1]

There are plenty of appliances you can use for soldering. Let’s discuss them!

Soldering station

Most soldering stations also come with a number of other features such as a digital display, adjustable temperature control, and a sleep mode function. These features can be very useful, particularly for those who do a lot of soldering.

Soldering stations are generally more expensive than regular soldering irons but they offer many advantages that make them worth the investment. For example, being able to adjust the temperature precisely can help to avoid damaging delicate components while still getting a good joint.

Additionally, since most soldering stations come with a stand, this can be very useful for keeping the iron in one place while you work. This can be particularly helpful when working on circuit boards as it prevents the possibility of accidentally shorting out any components.

Some stations also come with a tip cleaner which can be very helpful for keeping the tip of the iron clean and free from build-up. This ensures that the heat transfer is as efficient as possible and prevents any problems with the solder not sticking to the components.

You should also expect your station to come with a control box where you can change the settings and power the unit on and off. This is generally located at the front of the station for easy access.

While soldering stations are incredibly useful, they are not essential for every solderer. If you only do occasional soldering then a regular iron will suffice. However, if you do a lot of soldering or need to be able to adjust the temperature precisely then a station is definitely worth considering.

Again, it’s important to note that soldering stations are pretty pricey. If you want a top-of-the-line model with all the bells and whistles then you can expect to pay over $200. However, there are some very good quality stations available for around $100 which is still a significant investment but may be more affordable for some people.

Soldering gun

A soldering gun is a type of soldering iron that is used for heavy-duty work. It has a high power rating and can reach temperatures up to 700°F (370°C).

Soldering guns are not as precise as other types of soldering irons, so they are not ideal for delicate work. They are, however, well suited for joining thick wires and terminals. Soldering guns are a to-go choice for heavy duty work and heat up quickly too.

Soldering iron

A soldering iron is a hand tool used in soldering. It supplies heat to melt the solder so that it can flow into the joint between two workpieces. A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing an electric current (supplied through an electrical cord or battery cables) through a resistive heating element.

The tip of the soldering iron gets very hot but the temperature range is lower than that of a soldering gun. Still, it’s important to be careful when using one and to avoid touching the hot tip. Always unplug the soldering iron when you’re not using it and be sure to allow it to cool down before storing it.

The size and shape of the tip is another important consideration. The most common tip shapes are chisel, conical, and needle. Chisel tips have a wide, flat surface that is good for soldering larger surfaces. Conical tips have a small, round point that is good for precision work. Needle tips have a long, thin point that is good for detailed work.

There are also soldering irons that have interchangeable tips, which can be useful if you do a lot of different types of soldering projects.

Soldering irons are mainly used for light and medium duty work, such as soldering electronic components to PCBs. They are very flexible and easy to manipulate, which makes them well-suited for detailed work.

One advantage of using a soldering iron is that it’s relatively inexpensive and easy to use. However, one downside is that they take longer to heat up than other types of soldering appliances. Soldering irons also won’t provide as much power as some of the other options.

Soldering system

A soldering system is similar to a soldering station, but it allows you to connect multiple soldering instruments to a single power source. This can be useful if you have multiple solderers working in the same area, as it reduces the risk of tripping over cords.

A soldering system typically consists of a power unit, a control unit, and one or more soldering tips. The power unit provides power to the system, while the control unit regulates the temperature of the soldering tips.

For example, some soldering systems allow you to connect soldering iron and hot twizzlers to the same power unit and control the temperature of both instruments with a single controller. This can be very convenient, as you don’t have to keep switching between different power sources.

Soldering systems are available in a variety of sizes and configurations, so you can find one that suits your needs.

Hot twizzlers

Another advantage of hot twizzlers, is that they allow you to grab the smallest of components and solder them in place. This is perfect for those who are just starting out with soldering, as it can be difficult to hold onto tiny parts with your hands.

The only downside of hot twizzlers, is that they can be a bit dangerous to use. If you accidentally touch the hot metal tip, you could easily burn yourself. It is important to be careful when using these tools, and always keep them away from children.

Hot twizzlers are typically used for soft soldering projects, such as electronics. However, they can also be used for other types of soldering if necessary.

Hot air workstation

A hot air workstation, also known as a reflow oven, is used for soldering electronic components to a PCB. The process of soldering with a hot air workstation is called reflow soldering.

Hot air workstations come with a heat gun specifically for SMDs (surface-mount devices), which are small electronic components that are soldered to the surface of a PCB. The heat gun is used to heat up the entire board so that the solder paste can flow and form a connection between the component and the board all at once.

The advantage of using a hot air workstation over a soldering iron is that you can solder multiple components at the same time. This is because the heat gun can evenly distribute heat over the entire surface of the PCB.

Another advantage of using a hot air workstation is that it can be used for other purposes such as desoldering, heating, and drying.

The disadvantage of using a hot air workstation is that it is more expensive than a soldering iron. In addition, it takes longer to learn how to use a hot air workstation than it does to learn how to use a soldering iron.

Hot air workstations are best suited for people who are professionals or who do a lot of soldering and know how to use the appliance. If you are a beginner, it is recommended that you start with a soldering iron.

As you can see, out of these, soldering stations are the most expensive and the most versatile. That being said, they are also not always necessary – especially if you are just starting out with soldering. Now that we know the basics, let’s take a closer look at Hakko and Weller soldering stations. [2]

What is Hakko?

The company has over 60 years of experience in the industry. Hakko’s products are known for their quality, durability, and reliability.

Hakko’s most popular product is the FX-888D soldering station. The FX-888D is a digital soldering station that comes with a temperature control unit, a power unit, and a soldering iron. The FX-888D also comes with a carrying case and an instruction manual. [2]

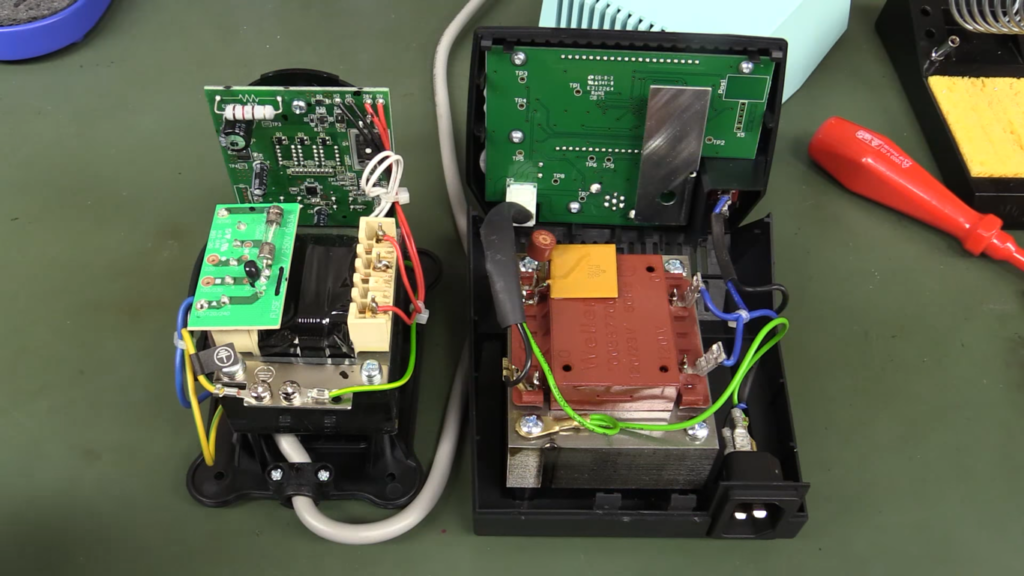

What is Weller Brand?

Weller is a brand that produces soldering irons and stations, fume extractors, and other accessories for the electronics industry.

Weller’s product line includes both entry-level and professional-grade soldering irons and stations. The Weller WE1010NA is a popular entry-level soldering station that sells for around $100.

Weller soldering stations are used to heat the metals being joined, as well as the solder itself. These stations come in a variety of shapes and sizes, but all include a heating element and a tip that can be swapped out depending on the project at hand. [2]

Comparison of Hakko and Weller Soldering Stations

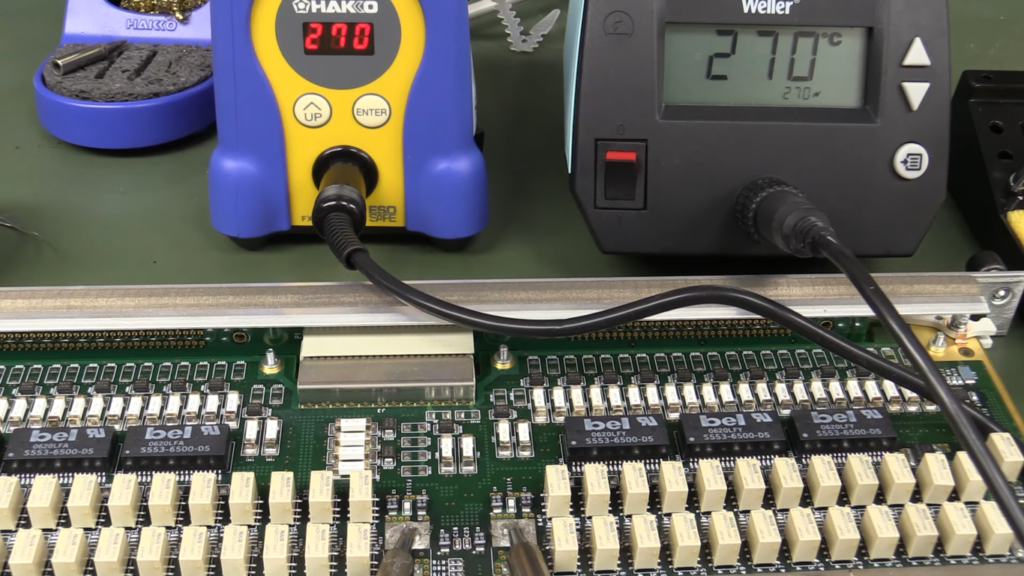

Now that we have looked at both Hakko and Weller, let’s compare the two brands. Both Hakko and Weller offer a wide range of soldering products, from entry-level to professional-grade. Let’s compare their two models, The Weller WE1010NA and Hakko’s FX-888D.

Performance

The first thing we’ll look at is performance. How well do Hakko and Weller soldering stations work?

Both soldering stations are rated at 70W of power, which is more than enough for most soldering applications. But this is only part of the story. Now let’s take a closer look at the temperature range.

When it comes to soldering, temperature is key. If your soldering iron is too cold, it won’t melt the solder. If it’s too hot, you risk damaging the components you’re working with. That’s why a good soldering station needs to have a wide temperature range, so you can adjust as needed for whatever you’re working on.

The Hakko FX-888D has a temp range from 120 to 899°F (50 to 480°C), while the Weller WE1010NA has a range of 200 to 850°F (93 – 454°C). So, both stations have a wide temperature range that should cover most soldering applications.

From this we can see that the Hakko FX-888D has a slightly wider temperature range than the Weller WE1010NA. However, both stations have more than enough power and temperature range for most soldering applications.

Now let’s take a look at how fast these soldering stations heat up. This is an important factor, because you don’t want to have to wait around for your soldering iron to heat up every time you want to use it.

The Hakko FX-888D takes about 20 seconds to heat up to 600°F, while the Weller WE1010NA takes about 28 seconds. So, the Hakko station is faster to heat up than the Weller.

Finally, let’s take a look at temperature drops. This is when the temperature of your soldering iron drops after you’ve turned it on. It’s important because you don’t want your soldering iron to cool down too much in between uses, as this can make soldering more difficult.

The Hakko FX-888D has a lesser temperature drop than the Weller WE1010NA. This means that the Hakko soldering station will maintain a more consistent temperature, making it easier to use.

Overall, we can see that the Hakko FX-888D is a better performing soldering station than the Weller WE1010NA. It has a higher power rating, a wider temperature range, and faster heat-up time. It also has less temperature drop, meaning it will maintain a more consistent temperature. [2], [3], [4]

Controls

Next factor we’ll look at is controls. How easy is it to use Hakko and Weller soldering stations?

No matter if you’re a beginner or a seasoned professional, you want a soldering station that is easy to set up and use. Both Hakko and Weller offer stations that are relatively easy to use. Two brands have a LCD display with digital controls that allow you to set the temperature precisely. This gives them an edge over stations with analog controls that can be more difficult to use.

However, there are still some differences between the two. Hakko station has a smaller footprint and is lighter than the Weller. The footprint of a soldering station is the total area that the unit and all its accessories occupy when in use. This is important to consider because it will determine how much space you have on your workbench. A larger footprint means that you’ll need a bigger workbench or more space around your soldering station. If you don’t have enough space, it can be difficult to use the soldering station and you may find yourself constantly moving things around.

Small footprint and lightweight design are both big pluses for the Hakko station. If you have a small workbench or limited space, the Hakko will be the better choice. The Weller is still a good soldering station, but it’s not as convenient to use in tight spaces.

Still, there are some downsides. For one, the power button is located at the side of the Hakko, which can be easy to accidentally turn off when you’re using the soldering iron. Some people might consider this a dealbreaker, but it’s not a big issue in my opinion.

Hakko’s setting buttons also could use some improvement. Unfortunately, there’s just two of them. When it comes to arrow keys, there’s only an “Up” button which makes it difficult to decrease the temperature quickly.

Settings also aren’t very intuitive and will definitely require you to read the manual before using the soldering station. Overall, the Hakko soldering station is not as user-friendly as the Weller, but it’s still a decent choice.

Now, how does Weller hold up?

Let’s start with a footprint again. Weller has a bigger footprint than Hakko which means you will need more working area to use it. Still, they managed to maintain it’s compact size regardless of that.

The screen is bigger too, which makes it easier to see the readings. You can really get a full view of the settings, and can see both current and the set temperature on the single screen!

As temperature drops, the screen will update in real-time to show you the new temperature.

Weller also shines in the control department. The Weller is a bit easier to use than the Hakko with its three-button control panel. Buttons are located on the front of the station and are clearly labeled, which makes it easy to find the right one. The power button is also located in the front, making it less likely that you’ll accidentally turn off the soldering iron and it’s easier to reach too.

It’s also easy to change the temperature with the Weller. There’s an up and down arrow key that allows you to quickly adjust the temperature. You can also hold down either button to increase or decrease the temperature at a faster rate. This is really helpful when you’re trying to dial in the perfect temperature for your project.

Although it’s not as powerful, it clearly is a winner in controls, user-friendliness, and design. [2], [3], [4]

Stand

What makes soldering stations different from other soldering appliances is that they come with a stand. The stand holds the soldering iron when you’re not using it and also has a sponge or brass wool to clean the tip of the iron.

A good stand will keep the soldering iron safely out of the way when you’re not using it and make it easy to grab when you need it. It should also have a place to store your extra tips so they don’t get lost.

The Hakko station comes with a solid and sturdy stand that does all of these things. Even if you bump into it, the Hakko is unlikely to tip over.

In addition to that, Hakko’s stand offers two ways to clean the soldering iron tip. There’s a brass wool pad for scrubbing off stubborn residue and a sponge for quickly wiping away any excess solder.

But how easy if Hakko’s stand to disassemble? The Hakko’s stand is actually very easy to take apart. You can quickly remove the top of the stand and clean it with a brush. This will further extend the life of your soldering station.

The Weller’s stand is also easy to use. But it’s not as advanced as Hakko’s. The stand has a spring holder which makes it wobble a bit when you set the soldering iron in it. It too has cleaning accessories, but they are limited to a single sponge.

Still, Weller’s stand has a nice tips storage that can keep four tips organized and within reach. This is really helpful if you have a lot of different projects that require different tips. Although it’s not as sturdy, the Weller’s stand is still pretty good. [2], [3], [4]

Accessories

Obviously, the soldering iron is the most important part of the soldering station, but there are other accessories that can make your life easier.

The Hakko FX-888D comes with a T18-B .05 conical tip that is of superior quality. The Hakko T18-B tip is made of a high-quality alloy that allows for precise heat transfer and long lasting durability.

However, the WE1010NA doesn’t fall behind in this category. It comes with a ETA .062 screwdriver tip that is also made of a high-quality alloy that ensures precise heat transfer and long lasting durability.

So both stations are equal in this category. [2], [3], [4]

Value

Finally, let’s talk about value. Which soldering station offers the best bang for your buck?

The Hakko FX-888D is usually 10% cheaper than the WE1010NA. So, if you’re looking for the best value, Hakko is the way to go. [2], [3], [4]

Tips for Extra Accessories

While soldering stations come with the basics, they rarely have everything you need in the box and that’s understandable. For this reason, we compiled a list of extra accessories that you might need for your soldering station.

Safety glasses

You might think that you don’t need safety glasses because the soldering iron is not that hot. But, trust us, you don’t want to get burned by a piece of solder that flew off while you were working. So, do yourself a favor and get a pair of safety glasses. They’re not that expensive and they will protect your eyes from flying debris.

Helping hand

Helping hand is essentially an alligator clip on a stand that can be adjusted to position the workpiece in just the right spot. This is especially useful for working on small components or soldering in hard-to-reach places. Soldering can be a tricky task, so having a helping hand to hold your workpieces can be a lifesaver!

Rosin core solder

While there’s many solder options out there, we recommend using rosin core solder for your soldering station. This type of solder is easier to use and it will result in a stronger connection.

Lead solder with rosin core is known for being the best type of solder to use as it has a lower melting temperature and is easier to use when compared to the lead-free solder.

Soldering mat

A soldering mat is one of those must-have accessories for any soldering station. It’s a heat resistant mat that you can put your tools on while you work. It protects your work surface from heat damage and keeps your tools organized.

Soldering mats come in a variety of sizes, but we recommend getting one that’s at least 12″x16″. That way, you’ll have plenty of room to work without having to worry about things getting too close to the edge of the mat. Soldering mats are relatively inexpensive, so there’s no excuse not to have one! [2]

FAQ

Is Weller a good soldering brand?

Yes, Weller is a good soldering brand. They make high-quality products that are durable and reliable. With proper care, a Weller soldering station will last for many years.

Where are Hakko soldering stations made?

Hakko soldering stations are made in Japan. What’s more, the company has a strong focus on quality control, so you can be sure that you’re getting a well-made product.

However, certain products may be outsourced to other countries, such as China. This is usually done in order to keep costs down. Still, Hakko maintains a high level of quality control, so you can be confident that any product you purchase will be up to par.

Do Weller tips fit Hakko?

The answer is no, and using a Weller tip on a Hakko soldering station will damage the iron. Hakko uses its own proprietary tips which can only be used with their irons.

Weller tips will simply be too small to fit snugly on a Hakko iron. For this reason, it’s important to only use Hakko tips with their irons, as this will ensure the best possible fit and connection.

Using a different brand of tip on a Hakko iron can cause problems such as poor heat transfer, which can in turn lead to longer soldering times and inferior results.

Useful Video: Weller vs Hakko solder stations | JoeteckTips

Conclusion

So, which is the better soldering station? The answer may not be as simple as you’d expect. The truth is, both Weller WE1010NA and Hakko FX-888D are excellent soldering stations that will do a great job for most people.

The Hakko FX-888D is our top pick because it’s more versatile and packed with more accessories than the Weller WE1010NA. In addition to that, it also offers better temperature ranges. However, it’s not as easy to use as the WE1010NA.

Weller is still a good station, we just feel that Hakko offers more bang for your buck. But at the end of the day, it all comes down to personal preference. We hope this guide has helped you make a decision!

If you have any questions, feel free to post them in the comments below and we’ll do our best to answer them. Thanks for reading and happy soldering!

References

- https://www.twi-global.com/technical-knowledge/faqs/what-is-soldering

- https://vsearch.com/weller-vs-hakko/

- https://core-electronics.com.au/guides/prototyping/soldering-showdown-hakko-vs-weller/

- https://www.nytimes.com/wirecutter/reviews/best-soldering-irons/

Leave a Reply