When it comes to electronics, there are a few fundamental skills that everyone should know: how to solder, how to use a multimeter, and how to breadboard. But what if you want to do more with electronics than just solder them together?

What if you want to make something that isn’t possible with a soldered circuit? In this article, we’ll discuss some alternatives to soldering and show you how they work!

3 Effective Alternatives to Soldering Electronics

Heatless Soldering

This process uses pressure to join the wires together. It is ideal for applications where you need to join the wires together again and again. Heatless soldering is a good alternative to traditional soldering because it is reliable and repeatable. [1]

The Twisting Fold-Over and Shrink Wrap Tubing Technique

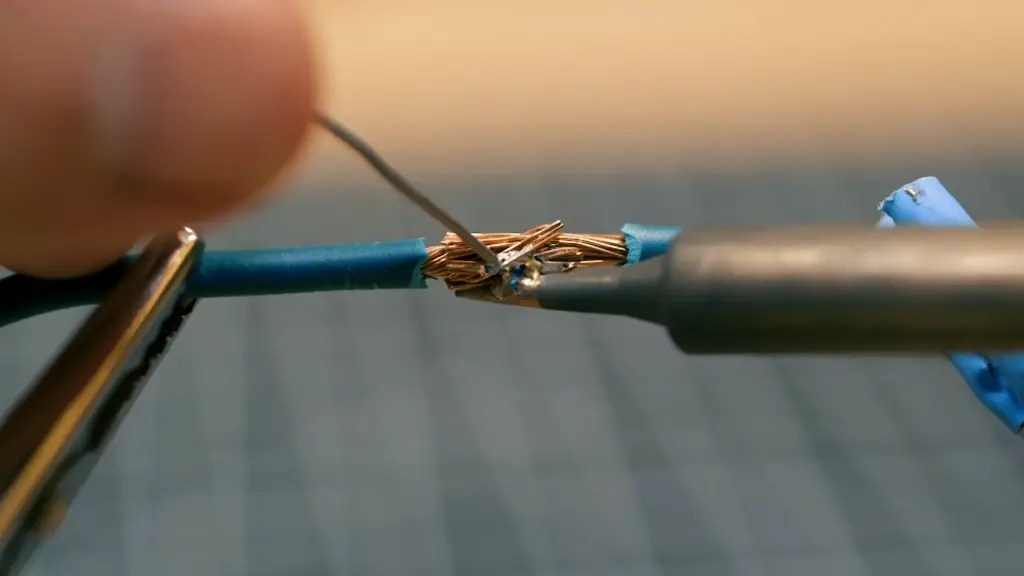

Another way to join two wires together is by using the twisting fold-over and shrink wrap tubing technique. This involves twisting the two wires together, folding them over each other, and then sliding a shrink wrap tube over them.

The heat from the shrinking process will hold the wires in place. This technique is ideal for applications where you need to make a secure connection but don’t have access to a soldering iron.

The Rosin Soldering Wire “Trick”

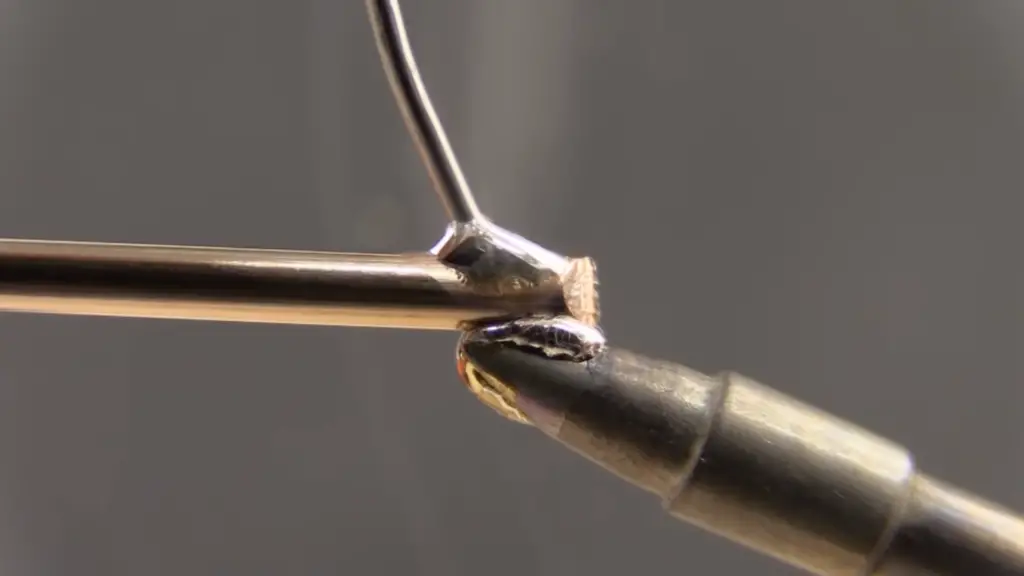

This is done by twisting the two wires together, covering them with rosin flux paste (this helps prevent oxidation and corrosion), and then wrapping them with solder wire.

The solder will melt from the heat generated by friction between the wires, creating a secure connection. This technique is ideal for quick, on-the-go repairs where you don’t have access to a soldering iron or other tools. [1]

Materials Needed

Connecting Wires

No matter which technique you choose to use, the first step is always connecting two wires together. This can be done by stripping and twisting the two wires together or using a connector such as a breadboard jumper wire, alligator clip, or banana plug.

Heatless Soldering Tool

If you are using the heatless soldering technique, you will need a specialised tool to apply pressure and secure the wires. This is usually made of metal with an adjustable thumbwheel used to apply pressure.

Shrink Wrap Tube

If you are using the twisting fold-over and shrink wrap tubing technique, you will need a shrink wrap tube. You can find these tubes in most electronics stores in different sizes.

Rosin Flux Paste and Solder Wire

If you are using the rosin soldering wire “trick”, you will need some rosin flux paste and solder wire. Both can be found at most hardware and electronics stores.

Liquid Rosin Flux Remover

If you are using the traditional soldering method, you will also need a liquid rosin flux remover. This is used to clean off any excess solder from the joint.

Heat Shrink Tubing

Finally, if you are using any of the alternatives to soldering mentioned above, you may also want to use some heat shrink tubing. This is a flexible plastic tube that is used to insulate and protect electrical connections.

Use of Conductive Adhesives

Conventional Conductive Adhesives

This type of adhesive uses specialised glue with conductive particles in it. It makes a thin film on the surface of the component and creates a reliable connection.

Silver-Loaded Conductive Adhesives

In addition to conventional conductive adhesives, there are silver-loaded conductive adhesives. These adhesives are similar to the traditional type but have a higher concentration of silver particles. This makes them more electrically conductive and reliable. They are often used when making connections with more power. [2]

Electrically Conductive Adhesives Using Nanoparticles

Electrically conductive adhesives can also be made using nanoparticles. These adhesives are very strong and reliable but require specialised equipment to apply them correctly.

Overall, there are many alternatives to soldering available for making electrical connections. Whether you need a quick fix or a long-term solution, one of these techniques is sure to suit your needs. With the right tools and knowledge, anyone can make reliable electrical connections without soldering.

Disappearing Liquid Phase Adhesives

Finally, there are disappearing liquid phase adhesives. These are special adhesives that disappear when heated to a certain temperature. They are ideal for making quick repairs or connections in tight spaces where soldering is not practical.

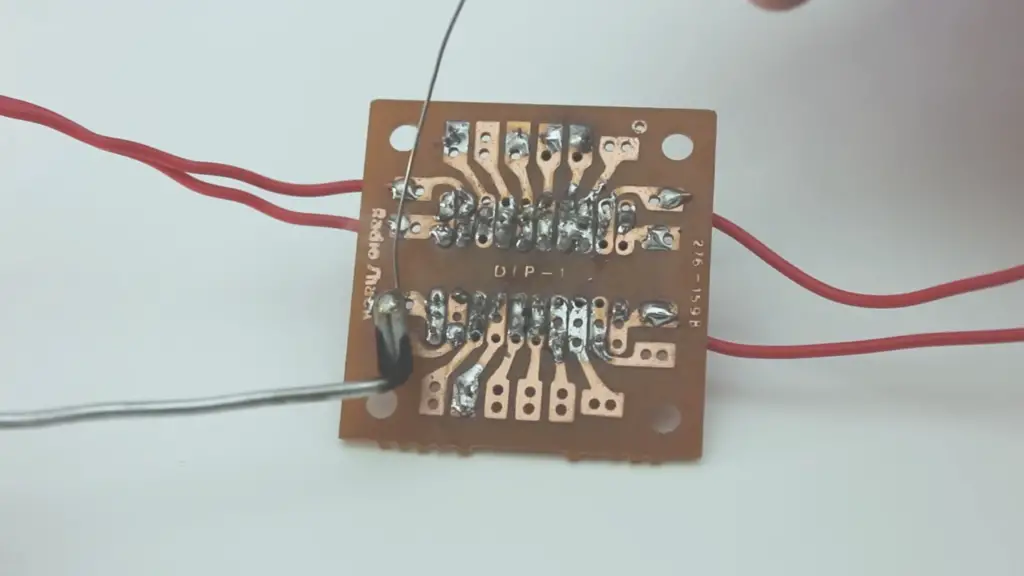

Use of Structures With Built-In Elements

In addition to using conductive adhesives, there are also structures that use built-in elements. These can include printed circuit boards (PCBs), connectors, and other components. These are often used in larger projects or when making connections between multiple components.

Use of Spring Contacts

Finally, there is the option of using spring contacts. These are special contacts that use pressure to make a connection with the surface of a component. They are often used when making connections in tight spaces or with delicate components.

No matter what type of electrical connection you need to make, there are alternatives to soldering available.

With the right tools and knowledge, anyone can make reliable connections without soldering. From conductive adhesives to structures with built-in elements, there are plenty of options available for making electrical connections without soldering. [2]

Types of Alternative Tools for Soldering

Battery-Based Soldering Device

One of the most popular tools for soldering is a battery-based soldering device. This type of tool uses batteries to generate heat, which can be used to melt the solder and make electrical connections.

Ultrasonics Soldering Device

Another type of alternative tool for soldering is an ultrasonic welding device. These devices use high-frequency vibrations to create heat, which is used to melt the solder and make electrical connections.

Laser Soldering Device

Finally, there are laser soldering devices. These tools use focused beams of light to generate enough heat to melt the solder and make a reliable connection. Laser soldering is often used for delicate components that require precise connections.

There are many different types of soldering tools that are available today. You can find tools that use batteries or lasers. With the right knowledge and practice, you can make reliable electrical connections without using solder.

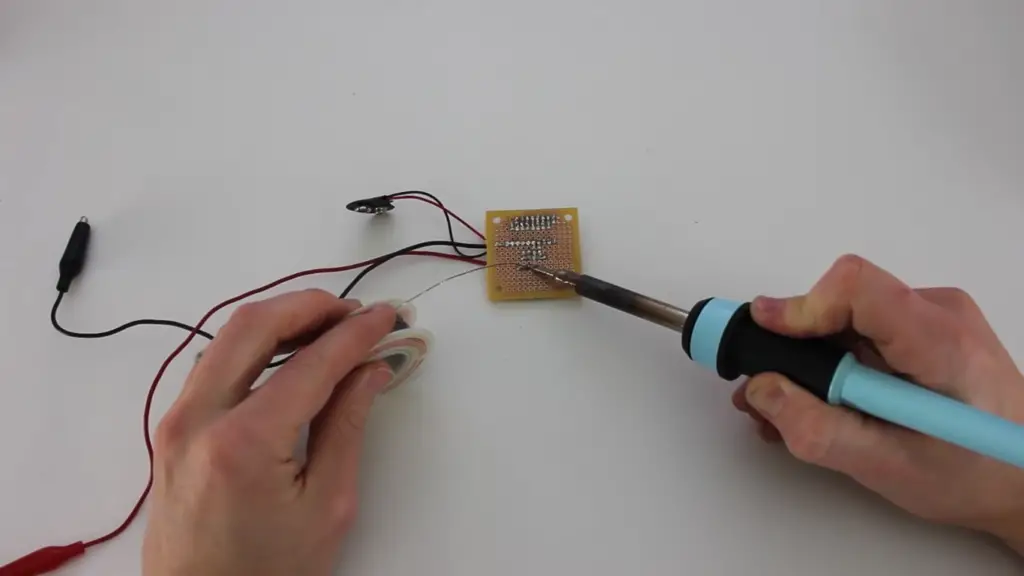

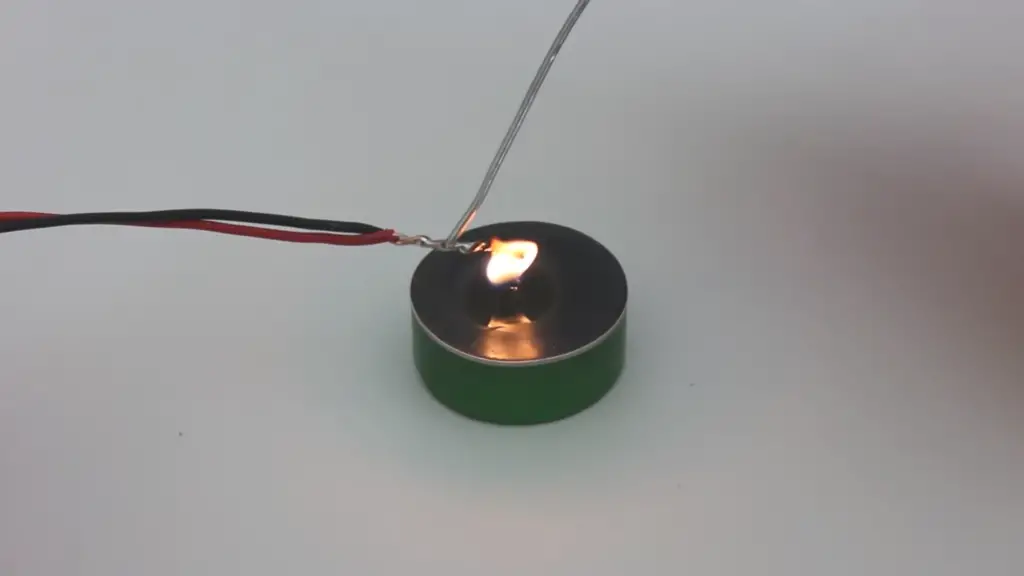

Soldering Iron From a Lighter and a Paperclip

If you don’t have a soldering iron, there is another way to connect electrical wires. You can use a lighter and a paperclip. The heat from the lighter will melt the solder on the paperclip so it can be used as a makeshift soldering iron.

Special Alloy for Soldering Without a Soldering Iron

If you don’t have a soldering iron but still need to make an electrical connection, there is one more option. You can use a special alloy that melts at relatively low temperatures. This makes it possible to solder without the use of a soldering iron.

Making electrical connections doesn’t have to involve soldering. You can use different tools and techniques to do this without using solder. There are many ways to do this, like using conductive adhesives or structures with built-in elements.

You can find a way that works for you, whether you need a quick fix or a long-term solution.

FAQ

What to use instead of soldering?

There are a number of alternatives to soldering that can be used, such as conductive adhesives, structures with built-in elements, spring contacts and battery-based solder devices.

What is the best tool for soldering?

The best tool for soldering depends on the task at hand. For small tasks requiring precision, a battery-based soldering device is often used. For larger projects, ultrasonic welding devices or laser soldering devices may be more appropriate.

Can you solder without a soldering iron?

Yes, it is possible to solder without a soldering iron. You can use a lighter and paperclip to make a makeshift soldering iron. You can also use a special alloy that melts at relatively low temperatures without the need for a soldering iron.

Can you solder with a lighter?

Yes, it is possible to solder with a lighter and a paperclip. The heat from the lighter will melt the solder on the paperclip so it can be used as a makeshift soldering iron. You should use caution when working with a lighter, as they can be dangerous if not used properly.

How do I attach a wire without soldering?

There are a number of alternatives to soldering that can be used, such as conductive adhesives, structures with built-in elements, spring contacts and battery-based solder devices. These tools allow you to make reliable connections without using solder.

How do you solder without a solder?

You can use a special alloy to connect electrical wires without needing solder. This is a good idea because it’s safer and easier. However, you need to be careful when using these alloys because they can be dangerous if not used properly.

Is there glue that works like solder?

There are special types of conductive adhesives that can be used instead of solder. These adhesives are designed to make reliable electrical connections without the use of solder. However, it is important to note that these adhesives have their own set of risks and should always be used with caution.

Can you use a paperclip as solder?

You can use a paperclip as solder if you heat it with a lighter. The heat from the lighter will melt the solder on the paperclip so it can be used as a makeshift soldering iron. Be careful when using a lighter, because they can be dangerous if not used properly.

Can you use superglue instead of solder?

No, you cannot use superglue as a substitute for solder. Superglue is not an effective electrical conductor, so it will not make reliable connections. Instead, you should use a special conductive adhesive or another alternative to soldering.

Can you use aluminium foil as solder?

No, aluminium foil cannot be used as solder. Aluminium foil is not an effective electrical conductor and will not make reliable connections. Instead of aluminium foil, you should look into alternatives to soldering such as conductive adhesives or structures with built-in elements.

How do you make a simple solder?

You can make a solder by melting a special alloy. The alloy will melt at low temperatures and can be used to connect electrical wires. It is important to use caution when working with this type of alloy, as it can be dangerous if not used properly.

What are the 3 types of soldering?

The three main types of soldering are gas soldering, soft soldering and hard soldering. Gas soldering is done with a blowtorch or similar device, soft soldering is typically done with an electric solder pen or a battery-powered solder gun, and hard soldering is used for joining metals together at high temperatures.

Is soldering harder than welding?

Welding is stronger than soldering and it lasts longer. It takes more skill and knowledge to do welding, but it is worth it because the connections are so strong. Soldering is simpler and faster, but it is not as strong as welding and can be less reliable.

What are some tips for soldering?

Some important tips for soldering include cleaning the surfaces before soldering, wearing heat-resistant gloves, using flux to eliminate oxidation, and testing the joints after soldering. It is also important to use appropriate safety equipment such as goggles and masks when working with soldering tools.

What are the benefits of using alternatives to soldering?

There are many benefits to using alternatives to soldering, such as ease of use, cost savings, and safety. Alternatives, such as conductive adhesives or special alloys, are easier to use than solder and can save time and money.

They are also safer because they do not require the same level of heat that is used in traditional soldering. In addition, using alternatives to soldering can help reduce the risk of electrical shock.

It is important to consider all your options when it comes to making electrical connections. There are different ways to connect things electrically, and some are easier than others.

Soldering can be expensive and require special tools, but there are other ways to do it that are just as safe and reliable. With the right knowledge and preparation, you can make safe and reliable connections without ever having to pick up a soldering iron.

Is soldering worth learning?

Soldering is a skill worth learning. It can be very useful for any electronics project or repair. When you know how to solder, you can make strong, safe connections quickly. With the right materials and some practice, you can become an expert solderer in no time!

In addition, improving your soldering skills will also improve your troubleshooting and repair capabilities, making it easier to diagnose and fix any electronic issues. Soldering is a valuable skill that everyone should learn!

What is the poisonous metal from a solder?

Lead is a poisonous metal often found in solder. If you are using solder that contains lead, it is important to handle it carefully and use safety equipment, such as a face mask and gloves. If you are using an alternative to soldering that does not contain lead, then there is no need to worry about this.

What is the easiest metal to solder?

Typically, copper is the easiest metal to solder. Copper has a low melting point and is easy to work with. Other metals such as aluminium, brass, and stainless steel can also be soldered, but they require more skill and specialised equipment.

What are some alternatives to soldering?

Some alternatives to soldering include using conductive adhesives, crimping, and special alloys. Conductive adhesives are an easy and relatively inexpensive way to make electrical connections.

Is soldering a skilled job?

Yes, soldering is a skilled job. It takes practice and skill to properly solder connections. When done correctly, soldering can create strong and reliable electrical connections.

However, if it is done incorrectly it can result in weak or unreliable connections that can lead to electrical problems. It is important to take the time to learn the proper techniques and practise them until you feel confident in your abilities.

Is soldering a hard skill?

Soldering is a hard skill. It takes practice, patience, and attention to detail in order to master it. It can be intimidating at first, but with some guidance and practice you can become an expert solderer.

Additionally, there are many resources available online that can help you learn the basics of soldering. With the right resources and a bit of practice, you can become an expert solderer in no time!

What are three 3 hazards to be aware of when soldering?

There are three main hazards to be aware of when soldering: electrical shock, burns, and fumes. Electrical shock can occur if you touch a live wire while soldering. Burns can occur if the solder or components get too hot. Fumes can be hazardous when inhaled, so it is important to work in a well-ventilated area.

What are the four stages of soldering?

There are four steps when soldering: cleaning, tinning, heating, and applying solder. Cleaning is when you remove any dirt or oxidation from the surfaces that will be soldered.

Tinning is when you coat the surface with a thin layer of solder so the connection will be stronger. Heating applies heat to the parts that will be soldered so that the solder will melt. Applying solder is when you add the actual solder to make the connection.

What should I do after soldering?

After soldering, it is important to inspect your work. Make sure that all of the connections are secure and there are no loose wires or exposed metal.

You should also check for any shorts or other issues that may have occurred during the soldering process. Finally, you should clean up your work area and properly store your tools.

Why is it so hard to solder?

Soldering is hard because it needs a lot of accuracy. If you are not careful, the solder can come off. The things you are soldering also need to be clean before you do it.

This means that you have to clean the surfaces and put a layer of tin on them. You also need to heat them up before you join them together. It takes a lot of practice to be able to solder well.

What is the best solder for beginners?

The best solder for beginners is lead-free, rosin core solder. Lead-free solder is safer to work with and produces high quality connections. Rosin core solder comes in a variety of sizes and flows easily.

Beginners should also invest in a good soldering iron that has adjustable temperature settings so you can use the correct heat for each job.

Useful Video: Make a Soldering Iron With a LIGHTER & Do Repairs ANYWHERE!

Conclusion

So, what are your options if you don’t want to (or can’t) solder? There are a few different methods that you can use to connect two or more pieces of metal without using a soldering iron. One popular method is using adhesives. You can use epoxy, superglue, or even hot glue to attach the pieces together.

If you have some metalworking skills, you could also try welding or brazing the pieces together. These methods may take a little more time and practice than soldering, but they can be used to create strong joints without needing any special tools or equipment.

Have you tried any of these techniques for connecting metal parts? Let us know in the comments! With a bit of practice and the right tools, you can learn to make strong, reliable connections without having to solder.

We hope this guide has been helpful in showing you some of the alternatives to soldering.

References

- https://survivalfreedom.com/3-effective-alternatives-to-soldering-electronics/

- https://nerdytechy.com/alternatives-to-soldering/#

Leave a Reply