For anyone involved with any type of electronic wiring project, one question that comes up repeatedly is why solder is used for joining electrical wires together. It may seem like a simple process but there are actually many important reasons why this is the preferred method and it’s important to understand just what those reasons are if you want your project to be successful. In this blog post, we’ll look closely at why solder is such an ideal choice for connecting wires in all types of electronics by taking a more detailed look into the specific qualities of solder itself and how its properties can make or break your circuit. We’ll also examine some potential alternatives as well as discuss the importance of safety measures when working with electronics and their components.

What Is The Main Purpose of Using Solder to Join Electrical Wires?

This not only ensures that the electrical connection will remain secure, but it also helps prevent corrosion by protecting the metal surfaces from exposure to moisture and other elements.

Additionally, solder can create a conductive path for electricity, allowing electrons to more easily flow throughout the circuit.

Finally, solder provides additional insulation around the joint which reduces how much heat is generated during operation and helps reduce instances of electric shock. All in all, soldering is essential for making quality electrical connections that are reliable and safe.

Overall, using solder to join electrical wires is the best way to ensure secure connections that won’t corrode or break over time, and which provide excellent insulation and conductivity. This makes soldering a vital step in any electrical wiring project. With proper application, solder can help create strong and long-lasting connections that will stand up to even the most demanding conditions. [1]

A Deeper Look At Solder

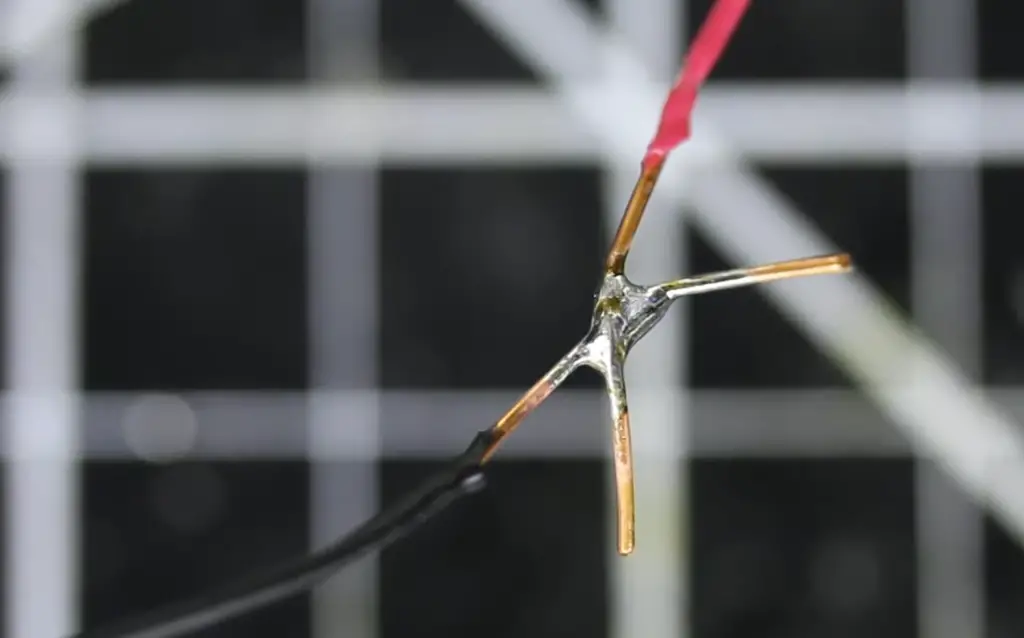

It is made up of two or more metals that are heated until they melt and then mixed together. When cooled, the molten mixture forms a strong bond between the joined pieces of metal.

The primary metals used in solder are usually lead and tin but other types are available for specialized applications, such as silver-bearing solders which can be used for joining certain types of stainless steel. The most common type of solder used today is 60/40 lead-tin blend containing 60% tin and 40% lead, although lead-free versions are becoming more popular due to health concerns with using lead based products.

Solder is important for electrical wiring and other metal-to-metal connections because it bridges the gap between two pieces of metal, creating a strong bond that can withstand heat, pressure, and vibration. It also helps to protect against corrosion and oxidation which can weaken or damage the metals over time. Solder joints are also much less prone to becoming loose or breaking apart due to thermal expansion and contraction caused by changes in temperature.

For these reasons solder is an essential material used in many different industries including electronics manufacturing, automotive repair, plumbing, and HVAC maintenance. It is easy to use and relatively inexpensive making it a popular choice for many applications where joining metals together is necessary. [2]

Different Types Of Solder

Solder is a metal alloy that comes in many different forms, each designed for a specific application. The most common types of solder are made with tin and lead, although some versions are lead-free.

Other alloys may also include silver, copper or antimony to enhance the properties of the solder material. Each type of solder has its own melting point and can be used to join different materials including metals and plastics.

Some examples include:

- Rosin Core Solder: This type of soldering material is widely used due to its low melting point (183-190°C) and general purpose applications. It is mostly composed of 60/40 tin/lead alloy and includes rosin flux core which helps in promoting the flow of solder.

- Lead-Free Solder: This type of solder is becoming increasingly popular due to environmental concerns and health risks associated with lead-based products. Its melting point lies between 217-220°C and it is composed mostly of tin, copper or silver alloys.

- Silver Solder: This type of solder has a higher melting point (above 800°C) than other solders and produces stronger bonds when joining metals. It is usually used for plumbing applications where high temperatures are required in order to melt the material. Silver solder also offers better conductivity compared to other types of solders.

Each type of solder has its own advantages and disadvantages depending on the application, but they all serve the same basic purpose: to join two components together. Solder is able to do this because of its low melting point, which allows it to flow and fill any gaps between two materials without creating a permanent bond. In addition, solder provides electrical insulation and prevents corrosion from occurring in metal joints.

These characteristics make solder an ideal material for joining electrical wires, enabling reliable electrical connections with minimal effort. With the right type of solder and proper soldering techniques, you can create strong and durable electrical connections that will last for years to come. [3]

Is Solder Used To Join Wires In Electronic Applications As Well?

Yes, solder is used for joining electrical wires in electronic applications as well. The use of solder ensures that the connection between two wires is strong and reliable. Solder can form a secure bond between two surfaces without any gaps or voids that could affect electrical continuity.

It also serves to protect the joint from elements such as moisture, dust, and debris which might otherwise interfere with its functioning. The low melting point of solder makes it an ideal choice for making connections in delicate components, since the heat generated during the soldering process won’t damage them.

Furthermore, the flux contained within solder helps to clean and protect metal surfaces, facilitating better electrical conduction across those surfaces. As such, using solder is vital when it comes to joining electrical wires, as it ensures a secure and reliable connection.

Overall, solder is indispensable when it comes to making electrical connections in electronic components and wires. By utilizing its properties of low melting point, good electrical conduction, protection from elements, and strong bond strength, it ensures that the connection between two wires will be robust and dependable. This makes solder an essential part of any electronics project or application.

Is There A Substitute For Solder To Join Electrical Wires?

Solder is a commonly-used material for joining electrical wires, as it provides a strong connection that will last for years. However, solder is not the only option available for connecting electrical wires. There are several other alternatives to solder which can be used for this purpose.

Another option is crimp connectors, which use an internal clamping mechanism to create a strong bond between two electrical wires. Crimp connectors come in various sizes, allowing them to be used with a variety of different wire types.

They provide a reliable connection that can last for many years and are also easier to install than solder connections due to their simple design.

Insulation displacement connectors (IDCs) are another option for joining electrical wires without the use of solder. IDC’s have two blades which pierce the insulation on either side of a wire when compressed together, creating an electrical connection. This type of connector is relatively easy to install and provides a secure connection. It is also resistant to vibrations, making it ideal for use in cars or other mobile applications where wires may experience movement during operation.

Finally, butt splices can be used to connect two electrical wires without the need for solder. Butts splices come in a variety of sizes and shapes, allowing them to be used with different types of electrical wiring. They consist of two metal pieces which are inserted into either end of the wire and then crimped together using pliers or special tools.

As these alternatives demonstrate, there are several options available for connecting electrical wires without the use of solder. Each one has its own advantages and disadvantages, so it is important to choose a method that works best for your particular application. Ultimately, no matter which type of connector you choose, it will provide a secure connection that will last for many years. [4]

Advantages Of Using Solder To Join Electrical Wires

Using solder to join electrical wires offers a number of advantages. Solder is quick and easy to use, making it the preferred method for many DIYers and professionals alike. Soldering also produces a strong connection that is resistant to vibrations and corrosion. The heat of soldering melts tin and lead together in order to seal the wire connection from external elements such as moisture or dust. This makes it an ideal choice for providing reliable connections in areas subject to extreme conditions or harsh environments.

In addition, soldered joints are highly conductive since they contain no air bubbles which could cause resistance points in the circuit. This means that soldered electrical connections are some of the most secure and dependable available today. When properly done, welding can create solid bonds that last for years without the need for repairs or maintenance.

Overall, soldering is an effective and convenient way to join electrical wires, providing a reliable connection with a strong bond to ensure safe operation for many years. By using solder to create connections, you can be confident your circuits will remain in working order and provide excellent performance.

What Is Used To Melt Solder To Join Electrical Wires?

Soldering is an important process for joining electrical wires that involves the use of a special type of metal alloy known as solder. While solder is capable of fusing metals together, it requires the application of heat in order to do so. This heat can come from either a soldering iron or a soldering gun. A soldering iron has a small tip that needs to be heated before use and applied directly onto the joint area between two wires. The tip should be kept hot enough so that the solder melts and flows into and around the connection, forming a secure bond.

On the other hand, a soldering gun uses increased electrical current whereupon pressing down on the trigger heats up its tip instantly and allows for much faster heating action when compared to a soldering iron. It is especially useful for larger projects that require the joining of multiple wires at once. For both devices, an appropriate rosin-core solder should be used in order to achieve optimal results.

In addition to heat and solder, flux is also necessary for successful soldering operations as it helps remove any impurities or oxidation from the wire connection area. This allows for improved electrical contact between the two metal surfaces and ensures that a strong bond can form. Flux comes in either liquid or paste form, with each providing its own unique benefits when used correctly. [5]

Can Solder Be Used For Welding Applications?

The short answer is: no. Solder is not used for welding applications due to the fact that it does not create a permanent joint and it does not have the same kind of strength as welding. Welding involves using extreme heat to join two metals together, often creating a bond that can last for decades or even centuries.

On the other hand, solder is a lower-temperature process which requires flux in order to create a strong connection between two metal surfaces. While solder may be suitable for electrical wiring connections, it cannot take the place of welded joints when strength and permanence are important factors.

For these types of projects, welding should always be considered first before resorting to soldering as an alternative solution. [6]

FAQ

Why is solder used for joining metals?

When heated, solder melts and forms a connection between two pieces of metal. This makes it easier to join wires together without having to use large amounts of heat or mechanical fasteners. Solder also provides additional protection from electrical shorts and corrosion due to its low temperature melting point. It can also withstand high temperatures which makes it perfect for applications such as soldering components on circuit boards. Additionally, solder is resistant to vibration and shock which helps protect joints against any kind of movement that could damage them in the long run.

What metals are usually used when soldering?

The most common type of solder is made up of tin and lead, but there are also solder alloys available that contain other metals such as copper and silver. Depending on the application, a different type of solder may be necessary to ensure a strong connection.

What are some common applications for soldering?

Soldering is commonly used in electronics assembly, plumbing, jewelry making, automotive repair and many other applications where joining two pieces of metal together is needed. Soldering can also be used to create connections between wires or components on circuit boards. In addition to connecting wires and components, solder can also be used as a filler material for certain metals that require extra support or protection. Additionally, it is often used in the production of stained glass windows due to its ability to seal small cracks without disrupting the overall design.

What kind of tools are needed for soldering?

Soldering requires a few basic tools including a soldering iron, solder, flux and some type of heat-resistant surface to work on. The most common types of soldering irons can range from small pen-sized models up to larger models with higher wattage ratings. Solder is available in different thicknesses or alloys depending on the particular application and needs to be applied directly onto the metal being joined. Flux aids in creating strong connections by removing any oxidation that may have formed on the metal surfaces prior to soldering. Finally, a heat-resistant surface such as a special mat or wooden block is needed to protect the surrounding area from damage due to high temperatures.

Is solder hotter than welding?

Solder is not as hot as welding, since the temperatures used to melt solder are much lower than those used for welding. This makes it easier and safer to join metals together, without having to worry about damaging the surrounding area or components with high heat. Additionally, soldering does not require a lot of skill or expertise compared to welding, which can allow even novice DIYers to create strong and reliable connections between pieces of metal.

Useful Video: How to Solder Wires Together (Best tips and tricks)

Conclusion

Solder is a great way to join electrical wires. It creates an airtight connection that prevents moisture and dirt from corroding the wiring. Since it has a low melting point, solder can be used on many different types of metal surfaces without melting any other components in the circuit board. The use of flux ensures a secure bond between the two pieces by removing oxidation from the surface and preventing further corrosion. Solder is also available in various sizes and thicknesses for specific applications, making it a versatile tool for creating reliable connections with wires and other components in electronic circuits. With its numerous benefits, it’s no wonder why solder continues to be the preferred method for joining electrical wiring around the world.

References

- https://byjus.com/question-answer/which-property-of-solder-alloy-makes-it-suitable-for-welding-electrical-wires/

- https://www.toppr.com/ask/question/why-solder-is-used-for-welding-electrical-wires/

- https://www.vedantu.com/question-answer/solder-used-for-welding-electrical-wires-class-11-chemistry-cbse-5fc7456a2b01962f7a3f3647

- https://www.vedantu.com/question-answer/solder-used-for-welding-electrical-wires-class-11-chemistry-cbse-5fc7456a2b01962f7a3f3647

- https://electronicguidebook.com/why-is-solder-used-for-joining-electrical-wires/

- https://www.twi-global.com/technical-knowledge/faqs/what-is-soldering

Leave a Reply