Choosing the appropriate wire gauge for an electric dryer is vital to guarantee safety and efficient functionality.This choice depends on various factors including the dryer’s specifications, the length of the circuit, and local code requirements. In this comprehensive guide, we will delve into the essential factors and offer valuable insights to empower you in making a well-informed decision.

Understanding the Necessary Wire Size for an Electric Dryer

When installing an electric dryer, it is important to understand what size wire is required in order to prevent overloading. The National Electrical Code (NEC) sets standards for the correct gauge and type of wire that needs to be used when connecting a residential electrical appliance such as a dryer.

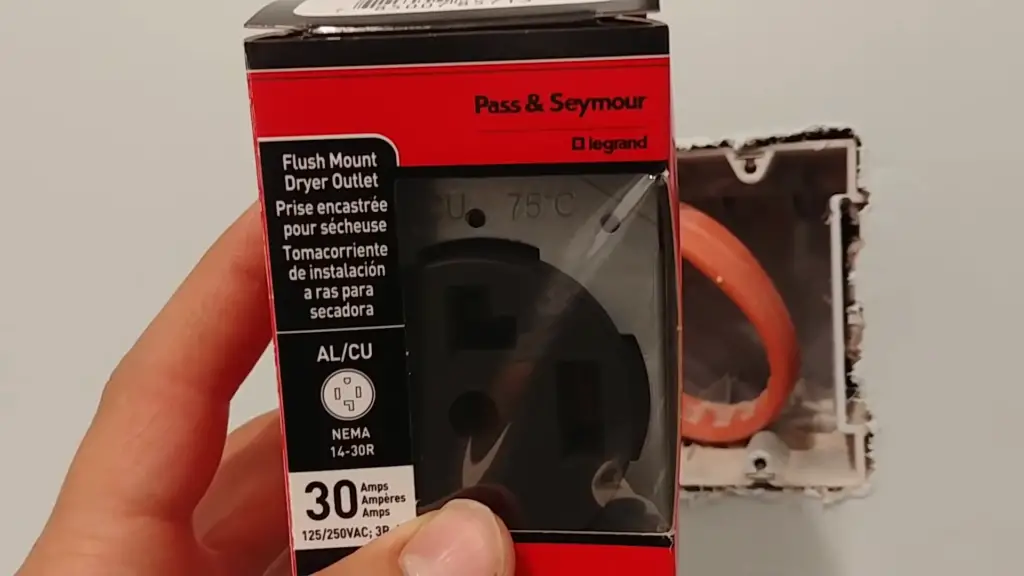

In the United States, electric dryers are usually powered by 220-volt circuits. To ensure optimal performance, it is advisable to use a minimum of 10 gauge copper wire with an insulation rating of 90° Celsius when connecting the appliance to the circuit breaker box. This specific type of wire is commonly known as a “10/2” cable, which consists of two insulated conductors and a bare ground wire. By following these recommendations, you can effectively establish a reliable connection.

To guarantee the safe and efficient operation of the electric dryer, it is necessary to upgrade the circuit with a dedicated 20-amp breaker, if it is not already equipped with one. In addition, installing a separate 30-amp circuit specifically for the dryer is also an option, although this may require additional wiring work.

It is important to note that the wiring should always be checked and approved by a licensed electrician before any connections are made. This ensures that all of the necessary safety requirements are met, and also helps to prevent potential hazards.

By taking the necessary precautions, you can help ensure that your dryer is properly wired and installed, and operates safely for years to come. [1]

Gauge of the Wire

The gauge of the wire determines its current-carrying capacity as well as the amount of voltage drop that will occur. For an electric dryer, 10 gauge wire is considered to be the minimum required in order for it to operate safely and efficiently.

A thicker, heavier wire (such as 8 gauge) has the advantage of being able to carry more current, but it will also be more expensive.

If the length of the wire run is particularly long or if the dryer is connected to a 20-amp circuit breaker, then 8 gauge wire may be necessary in order for it to meet the National Electrical Code requirements.

It is important to check with a qualified electrician before purchasing any wiring materials to determine the appropriate gauge of wire that should be used.

Connections and Terminations

In addition to using the correct type and size of wire, it is also important to use proper connections and terminations when installing an electric dryer. The ends of each conductor should be securely connected with approved connectors or terminals and all joints should be inspected for tightness and proper insulation.

When connecting the appliance to the circuit breaker box, it is important to make sure that the terminals are properly aligned and tightened in order to ensure a secure connection.

Finally, all connections should be covered with approved boxes or covers for safety purposes. This helps to protect against shock hazards as well as dust and debris buildup. [2]

Types of Wire

There are a few different types of wire available for electric dryer installations. The most common type is nonmetallic-sheathed cable (NM) which consists of two or more insulated conductors and a bare conductor ground wire. This type of wiring is typically used in residential settings and should be approved by the local building authority before installation.

Another option is the armored cable (AC) which consists of two insulated conductors and one or more bare ground wires that are all encased in a protective metal sheath. This type of wiring is usually used in areas that may be exposed to moisture or other environmental elements, such as basements and crawlspaces.

Regardless of the type of wiring being installed, it is important to ensure that it meets the NEC standards and is installed correctly in order to maintain safety.

Considerations Before Starting Installation

Before beginning the installation of an electric dryer, there are a few important things to consider. The first is to determine what type and size of wire should be used for the particular job. As mentioned earlier, 10 gauge wire with an insulation rating of 90° Celsius or higher is typically recommended for residential installations.

It is also important to make sure that the circuit breaker box is equipped with a dedicated 20-amp breaker, and that all connections are securely tightened and covered with appropriate boxes or covers.

Finally, it is important to read and follow the manufacturer’s instructions closely to ensure proper installation and operation of the appliance.

Installing the Correctly Sized Wire

Once you have determined the size of wire to use for your dryer, the next step is to install it correctly. Before starting, make sure that all power sources are turned off and that you have the appropriate safety gear such as gloves, goggles, and an arc-fault circuit interrupter (AFCI).

Start by cutting the wires to the appropriate lengths and stripping the insulation off each end. You need to make sure that there is enough exposed wire to connect it securely to the terminals on your dryer. Once this is done, you can begin connecting them according to the instructions provided with your dryer or in your local electrical code.

When doing so, take extra care not to cross any wires, as this could create a short circuit. Once all the connections are made, you can close up the wire box and turn on the power source to test it. If everything is working correctly, your dryer should be ready to use.

If you have any questions about what size wire for an electric dryer or need help with installation, don’t hesitate to contact a qualified electrician for assistance. With the right tools and knowledge, you can ensure that your dryer is properly wired and ready to go. [3]

Safety Tips When Working with Electricity

Whenever you are working with electricity, it’s important to take safety seriously. Make sure that the power source is turned off and double-check all connections before turning it back on. You should also wear protective gear such as gloves, goggles, and an arc-fault circuit interrupter (AFCI).

Never attempt to repair any wiring yourself, as this can be extremely dangerous. If you are ever in doubt, it’s best to contact a qualified electrician for assistance. They can provide the proper tools and advice needed to safely complete any electrical job. Following these safety tips will help protect you and ensure that your wiring is done correctly.

It’s also important to note that the size of wire used for an electric dryer can vary depending on the circuit load. Make sure to follow local codes and consult with a qualified electrician before starting any project, as this will help ensure that you are using the correct size wire. With proper installation and safety precautions, you can be confident that your dryer will work safely and efficiently. [4]

Benefits of Using the Right-Sized Wire

Using the correctly sized wire for your electric dryer is important for a variety of reasons. Not only does it ensure that the appliance runs safely and efficiently, but it can also help reduce energy costs over time. Properly installed wires will also last longer, meaning you won’t have to worry about replacing them anytime soon.

In addition, using the right size wire can help prevent electrical fires. Wires that are too small can create increased heat and resistance, both of which are potential fire hazards. Having the correct size wire in place will ensure that current is flowing properly and safely through your circuit.

Using the right size wire for an electric dryer is essential for safety, energy efficiency, and longevity.

Benefits of Professional Installation

Having your dryer professionally installed can bring many benefits, including:

- Ensuring proper safety protocols are followed

- A better guarantee that your appliance is properly connected and in good working order

- Reduced energy bills due to optimal wiring and connections

- Less risk of needing repairs or replacements down the road

- Peace of mind knowing your dryer is in the best hands possible

Professional installation may cost more up front, but it can save you money long term by avoiding costly repairs. Plus, you’ll have the added assurance of knowing that your appliance is properly and safely connected. [5]

FAQs

What size wire is typically used for an electric dryer?

The size of wire used for an electric dryer will vary depending on the circuit load. Generally, you should use 10 AWG (American Wire Gauge) or 12 AWG wire.

How do I know if my wiring is up to code?

You should always follow local codes and consult with a qualified electrician about what size wire to use for an electric dryer. A qualified electrician will be able to provide the correct tools and advice needed to properly install your wiring.

What should I do if my wiring is not up to code?

If you think that your wiring may not be up to code, it’s best to contact a qualified electrician for assistance. They can provide the proper tools and advice needed to safely complete any electrical job.

Are there any safety tips I should follow when working with electricity?

Yes! Whenever you are working with electricity, it’s important to take safety seriously. Make sure that the power source is turned off and double-check all connections before turning it back on. You should also always wear protective gear such as gloves, goggles, and an arc-fault circuit interrupter (AFCI). Never attempt to repair any wiring yourself, as this can be extremely dangerous. If you are ever in doubt, it’s best to contact a qualified electrician for assistance.

Is there a difference in wire size needed for gas dryers versus electric dryers?

Yes. Gas dryers typically require larger wire sizes than electric dryers due to the higher current demand. Make sure to check the requirements of your specific appliance before installing any wiring.

Can I install the wiring for my dryer myself, or should I hire a professional?

When it comes to installing the wiring for an electric dryer, it’s best to hire a professional. While it is possible to do the job yourself, there are certain safety considerations that must be taken into account. For instance, you need to make sure that all of your wires are properly grounded and rated for the correct amperage. Additionally, most local building codes require that any wiring installation be done by a certified technician.

In addition to safety considerations, it’s important to consider convenience when deciding whether or not to hire a professional. Unless you have experience with wiring installations, there is a risk of the project taking more time and effort than anticipated. Professional electricians are familiar with handling all kinds of wiring projects, so they can usually complete the job quickly and efficiently.

If you decide to hire a professional, make sure to ask for references from previous customers and check their experience level. The last thing you want is someone inexperienced working on your wiring installation. This could result in costly repairs or even safety hazards that could put your family at risk.

What happens if the wire size used for my electric dryer is too small?

If the wire size used for an electric dryer is too small, it can increase the risk of electrical fires. In addition to this, running your dryer with a wire that is too small can cause it to overheat and become damaged. This could result in costly repairs or even needing to replace your dryer altogether.

It’s important to make sure that you use the right size wire when wiring an electric dryer. If you’re unsure of what size wire to use, consult a professional electrician. They will be able to advise you on the best size wire for your specific situation and ensure that it is installed properly.

What are the regulations on wire size for electric dryers?

In the United States, the NEC (National Electrical Code) sets out rules for wiring an electric dryer. According to the code, a minimum 10-gauge wire is required for direct connection to a 30-amp circuit breaker. However, if you are connecting your dryer to a 50-amp circuit breaker, you will need to use a 6-gauge wire.

It’s important to ensure that the wiring used for your dryer meets local building codes. If you’re unsure of the requirements, consult a professional electrician who can advise you on the best size wire for your specific situation. This will help ensure that your dryer is safely and correctly wired, as well as meeting all applicable building codes.

How do I determine the correct wire size for my electric dryer?

When determining the size of wire to use for your electric dryer, you’ll need to consider several factors. First, you’ll need to know the voltage requirement of your dryer. This information should be on the manufacturer’s label located on the back or side of your appliance. Most residential dryers are 120/240 volts and require 10-gauge wire, but some may require 8-gauge wire.

Next, you’ll need to calculate the total circuit load of your dryer in order to determine the size of the breaker and wiring required. This calculation should also take into consideration any other appliances that will be on the same circuit, such as a washing machine or dishwasher. The National Electrical Code states that the maximum circuit load for a single appliance should be 80% of the breaker’s rating.

Finally, you’ll need to consider the length of your wiring run. Longer runs may require thicker wire due to voltage drop. According to NEC guidelines, longer wire runs require heavier gauge wire and may even require additional outlets or junction boxes along with an upgrade in breaker size.

How many amps is a 240V dryer?

The common standard for a 240V dryer is 30 amps. However, the actual amp rating for your dryer may vary based on the manufacturer’s specifications; this information should be found on the label located on the back or side of your appliance. A good rule of thumb is to always use wire that can handle at least 20% more than the rated amperage of your appliance. For example, if your dryer is rated for 30 amps, you should use 10-gauge wire (which can handle up to 40 amperes). If the manufacturer’s specifications indicate a higher amperage than 30 amps, then a heavier gauge wire may be required.

Do dryers use a lot of electricity?

Depending on the specific model of electric dryer you choose, it may require a different size of wire to ensure proper power is delivered. It’s important to make sure that the correct size of wire is chosen for your dryer to avoid potential damaging and costly problems. Generally speaking, an electric dryer needs 10 AWG (American Wire Gauge) copper wire for up to 30 amps of power, and 8 AWG copper wire for up to 40 amps of power. It is important to consult the owners manual or contact a professional electrician in order to choose the right size wire for your dryer.

In addition to choosing the right size wire, you should also make sure that any necessary fuses and circuit breakers are properly sized for your dryer. A fuse that is too small may not be able to handle the load of the appliance, creating a potential fire hazard.

Useful Video: How To Wire a Dryer Outlet or Receptacle – Materials Needed for Dryer Wiring

Conclusion

When it comes to selecting the right size wire for an electric dryer, safety should always come first. It’s essential to ensure that the wires are rated for the current being used and also correctly sized according to NEC regulations. Additionally, selecting the appropriate length of wire is crucial in order to minimize power losses and limit voltage droops at high current levels. Before beginning the installation of a dryer or any other electric appliance, it’s important to consult with a local electrician for advice and assistance. This will ensure that the job is done safely and correctly.

References

- https://nassaunationalcable.com/es/blogs/blog/which-size-wire-is-used-for-electric-dryers

- https://boggsinspect.com/what-size-wire-for-dryer/

- https://homeinspectioninsider.com/wire-breaker-size-electric-dryers/

- https://www.hunker.com/13410438/type-of-wire-gauge-to-use-for-an-electric-dryer

- https://conquerallelectrical.ca/dryer-wire-size-what-do-i-need-to-run/

Leave a Reply