Soldering is a process that involves joining two metals by melting a filler metal in between them. It’s commonly used in electrical and electronic circuits, and can be a great way to create reliable connections. In this article, we’ll discuss the basics of soldering, including what it is and how to do it. We’ll also take a look at reflow soldering, which is a type of soldering that is often used in electronics manufacturing. By the end of this article, you’ll have a better understanding of what reflow soldering is and why it’s such an important process!

Soldering in General

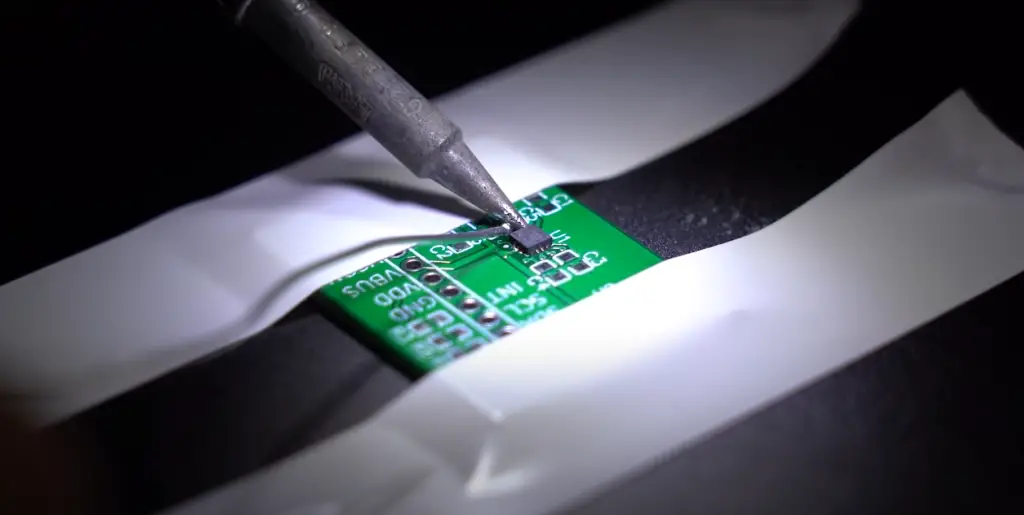

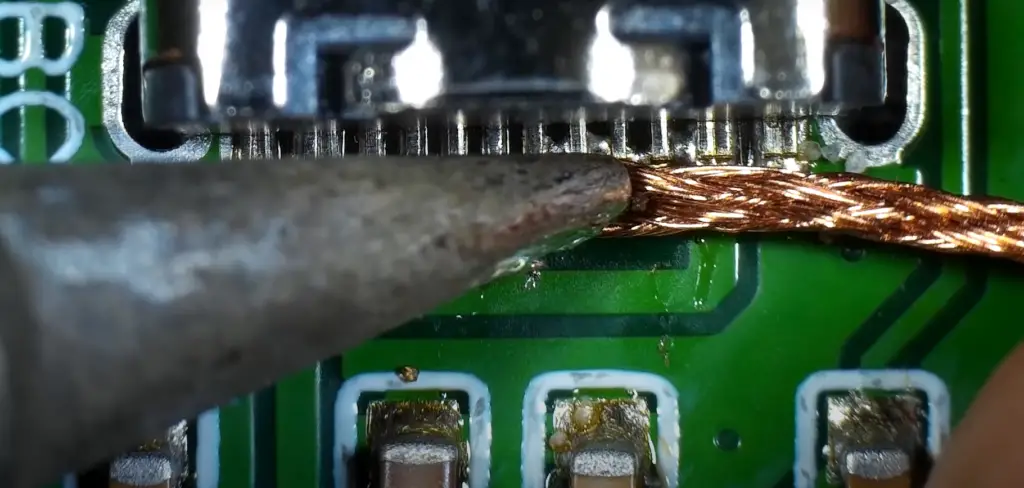

It is an essential skill in many areas of electronics, including the assembly of printed circuit boards (PCBs). The soldering process works by melting a small amount of solder material, usually made from a combination of lead and tin, between two metal surfaces. This creates a strong bond which can withstand high temperatures and electrical currents.

When done correctly, soldering can create reliable connections that last for years – even decades! In the following sections we’ll take a closer look at what reflow soldering is and how it differs from other forms of soldering. We’ll also provide useful tips on how best to approach the process in order to achieve the highest quality results. [1]

What Is Reflow Soldering?

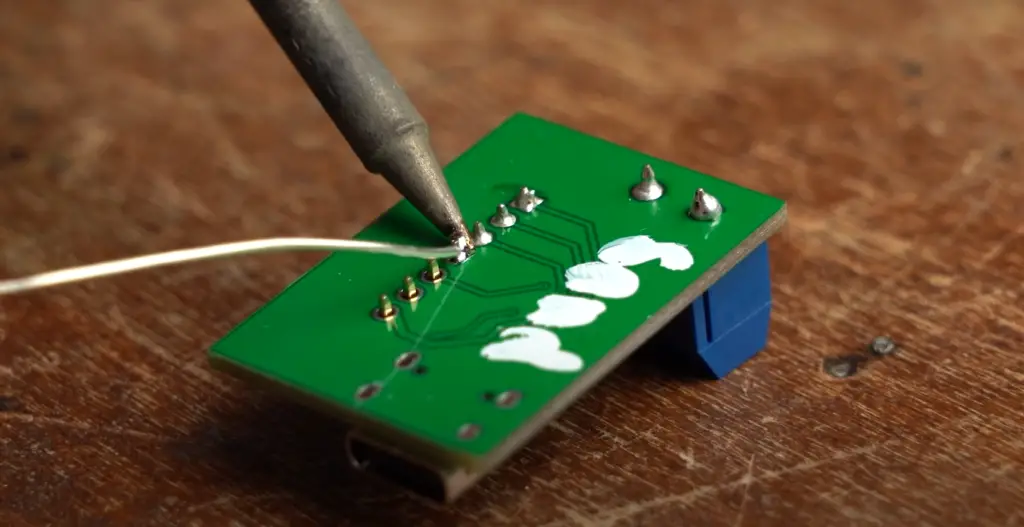

The process works by first applying small amounts of solder paste onto the surface of the PCB in areas where components will be mounted. Once this paste is applied, the board is placed into an oven and heated up until the solder melts and bonds with the component leads and surrounding metal on the PCB. This creates a strong electrical connection between component and PCB which can withstand high temperatures and currents.

Unlike traditional soldering, which requires manual placement of the soldered joints, reflow soldering uses a pre-designed layout for the connections between components. This makes it much easier to achieve precision in creating good electrical connections with little effort from the user.

In reflow soldering, each component has its own designated footprint on the circuit board – often referred to as a “land pattern” – where it will be installed. This ensures that all components are placed in the correct orientation and at the right distance from one another, so that they can easily establish proper electrical contact when heated.

What’s more, reflow soldering can be used to simultaneously connect multiple components at once. This makes it ideal for mass production as it allows for quick and efficient assembly of many PCBs at once.

And instead of using a soldering gun, reflow soldering utilizes hot air and/or convection ovens to heat up the solder and melt it into place. This ensures that the components are placed uniformly, with no component having too much or too little solder applied to it. [2], [3], [4], [5]

The Advantages of Reflow Soldering

Reflow soldering offers a number of advantages over traditional forms of soldering. Let’s discuss them!

Produces less thermal shock

One of the biggest benefits of reflow soldering is that it produces less thermal shock than traditional soldering. Thermal shock occurs when a component experiences too much heat during the soldering process, resulting in damage to the component and/or PCB. With reflow soldering, components are heated up slowly over an extended period of time which prevents any sudden changes in temperature that could cause thermal shock.

Extremely reliable technique

Reflow soldering is an extremely reliable technique as it creates strong electrical connections between components and the PCB which can withstand high temperatures and currents. This makes reflow soldering ideal for long-term applications such as automotive electronics or aerospace assemblies.

Suitable for SMT assembly

Reflow soldering is well-suited for surface mount technology (SMT) assembly. Surface mount technology (SMT) components are becoming increasingly popular in the electronics industry. And reflow soldering can be used to quickly and accurately attach small components such as integrated circuits (ICs), capacitors, and resistors to a PCB. As the process does not require any special tools or skill level, it makes SMT assembly faster and easier than ever before.

Doesn’t need constant monitoring

Unlike traditional soldering, reflow soldering doesn’t require constant monitoring. This saves precious time and effort as the process is automated and requires minimal attention from technicians.

Of course you still need to take measures when soldering, such as avoiding contact with the heated parts and being mindful of rapid temperature changes but these are minor precautions that don’t require constant monitoring.

It produces less wastage

Reflow soldering greatly reduces the amount of solder wasted, as compared to other manual soldering methods. The process is more efficient and precise, which allows for accurate control over the amount of solder used. This helps to ensure that no excess material is left behind that could potentially contaminate components or reduce the quality of a circuit board. Additionally, it also reduces the risk of safety hazards associated with repeated exposure to heated metals when manually soldering components. [4], [5]

What Affects the Reflow Soldering Process

Still, there are several factors which can affect the reflow soldering process. To ensure that the process is successful, you should consider all the below-mentioned factors before attempting a reflow soldering job.

Soldering machine

The most important factor in reflow soldering is the soldering machine. This device is responsible for controlling the temperature of the oven and therefore plays a major role in achieving successful results. When choosing a soldering machine, be sure to select one which can provide high accuracy and repeatability when it comes to heating the PCBs. Additionally, look for machines with advanced control features such as preheating and cooling stages, as these will help ensure that no components are damaged during the process.

The line speed of your soldering machine is also important, as it will determine how quickly you can complete the entire reflow process. Be sure to choose a machine with an appropriate line speed for your project – too slow and you may waste time, but too fast and components may be damaged. Generally, the line speed should be lower than the process speed of the machine to ensure that all components are properly heated and cooled.

Reflow profile

This cycle typically starts with pre-heat, followed by peak temperature, then ramps down and finally cools down. It’s important that these temperatures are strictly followed, as any variation can cause components to become damaged or even destroyed during the process.

Preheat

The preheat stage is the first and arguably the most important step of the reflow process. During this stage, the temperature of the PCB should be slowly increased until it reaches a normal soldering temp. This ensures a uniform heating of all components and allows solder paste to reach its liquidus point, which is required for proper bonding with components. The changes shouldn’t be more than 2°C per second to avoid thermal shock.

Thermal soak

The duration and pattern of the thermal soak depend on the solder paste being used and its specific melting characteristics. In most cases, soaking should last between a minute or two.

Reflow

Next we have the reflow stage, which is when the actual soldering takes place. During this stage, the temperature gradually increases until it reaches the peak temperature, or “reflow point”. This reflow point is determined by the solder paste being used and its melting characteristics.

To make sure the process goes as smoothly as possible, you must hold the solder paste at its reflow point for a set amount of time. This ensures that all components have been properly soldered and allows the solder to cool off in an even manner. Usually it should be between 30 and 60 seconds.

Cooling

The final stage of the process is cooling. This is where you allow the board to slowly cool until it reaches a safe temperature, usually around ambient temperature. During this stage, it’s important to ensure that the board remains stationary as any sudden movement can cause cracking or other faults in your newly soldered joints.

Just like with heating, the temperature drop must be gradual and consistent. The exact pattern of cooling depends on the solder paste being used and its specific melting characteristics but 3°C per second is a good rule of thumb.

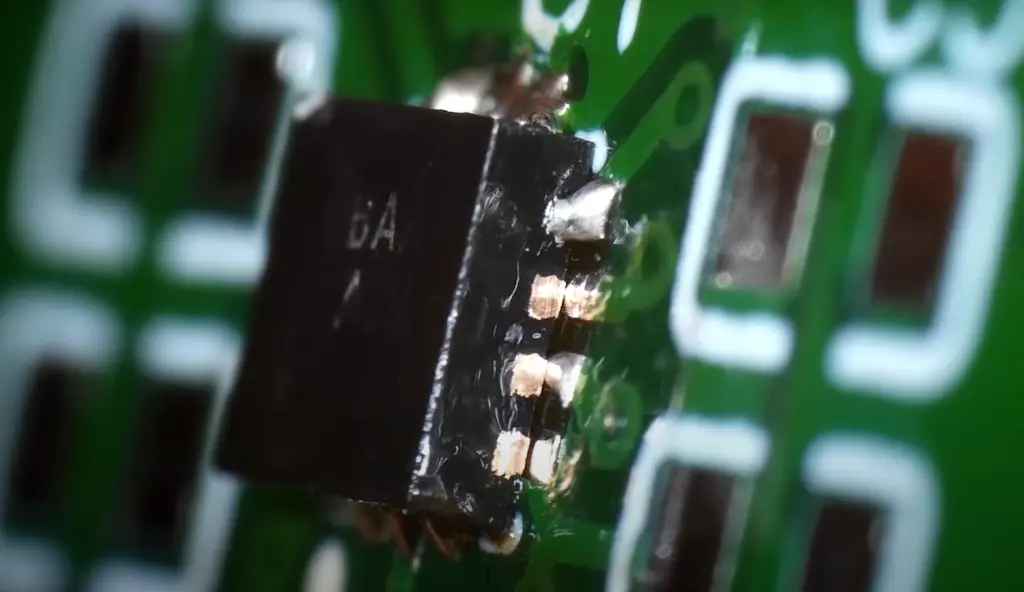

PCB and component design

The design of the PCB and components used are important factors in a successful reflow soldering process. The size and shape of the solder pads on the board should be large enough to accommodate the component leads and leave plenty of space for solder flow. Additionally, components with small lead pitches may need to be soldered from both sides as this increases the surface area available for solder flow.

If one side of the components is of a different size than the other, it can create a thermal imbalance on the board. This can affect the quality of the solder joint and cause uneven heating on the board. It is therefore important to ensure that both sides of the components are identical before beginning assembly.

Quality of components

The quality of the components used also plays an important role in a successful reflow soldering process. Low-quality components may not be able to withstand the high temperatures and pressures involved with reflow soldering. This can lead to damaged or faulty parts, resulting in poor electrical connections and unreliable performance.

When selecting components for your project, be sure to purchase parts from reputable manufacturers who guarantee their products against faults such as these. Additionally, you should always use genuine parts instead of cheaper counterfeits as this will ensure that your board is reliable and performs optimally.

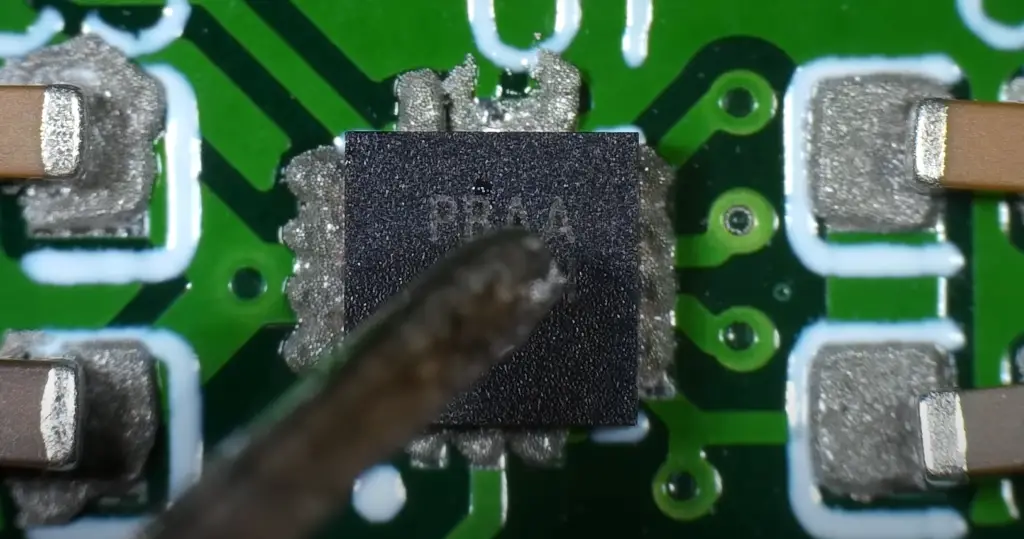

Placement of components

The placement of components is essential in ensuring that the reflow process runs smoothly. Components should be placed on the board with as little overlap as possible, and all leads should be aligned correctly before the soldering process begins.

And the component placement should be repeatable! This means that all components should be placed in the same order and manner, and any changes or corrections should be made before beginning the reflow process. This is done so that the machine’s vision system can more easily recognize the components and ensure a better soldering result. [2], [3], [4]

FAQ

Is soldering as strong as welding?

Soldering and welding achieve different objectives. In general, welding is a more permanent solution than soldering. Welding involves melting both materials to be joined together and then using an external pressure in order to bind them together. This creates a far stronger bond than soldering, where the materials are melted by heat, but no external pressure is used to pressurize the joint. Solder has higher tensile strength than welded joints, however because solder does not fill in all of the gaps between the two pieces it may lack some durability compared to a welded joint when exposed to high levels of stress or strain.

So, while soldering is not as strong as welding, it can still be relied upon for a secure and permanent connection for many applications provided that the joint undergoes minimal stress in its lifetime. Additionally, soldering does not require the use of special tools such as a welder or torches, and is relatively simple to perform.

What is reflow soldering used for?

The most common application for reflow soldering is in surface mount technology (SMT) assembly, where small surface mount components such as capacitors, resistors and integrated circuits are attached to a PCB . In this case, solder paste is first applied across all of the pads on each side of the board. Then the SMT components are placed in their exact positions before the board is placed in a reflow oven. The heat inside the oven causes the solder paste to melt and flow around each component, creating an electrical connection once it cools down.

In addition to SMT assembly, reflow soldering can also be used for through-hole components such as connectors or transformers. In this case, pre-formed pieces of wire are inserted into each hole on the PCB before the board is placed in a reflow oven. The molten solder forms connections between the wires and pads on both sides of the board.

How do you reflow a solder?

This is usually done by placing the assembled board in a special reflow oven, which uses infrared radiation to heat the board and melt the solder paste. The oven then cools the board down quickly, allowing the newly formed electrical connections to solidify.

What is meant by reflow?

It is an essential part of the PCB assembly process. Through reflow soldering, a wide variety of high-quality electrical connections can be made that are reliable and stable over time.

Unlike traditional soldering, reflow uses hot air to heat up the entire board at once. This allows for very precise and efficient soldering, with little room for error. In addition to this, reflow takes a fraction of the time it would take to solder each component separately by hand. It is also much more cost-effective since it requires less labor.

What is the difference between reflow and wave soldering?

Reflow soldering and wave soldering are two distinct processes used to join electronic components to a printed circuit board (PCB). As their names suggest, the two processes involve different techniques for achieving the same goal: joining components to a board.

Wave soldering is an older technology that uses a pool of molten solder kept at a constant temperature by means of liquidized flux. Components are placed on the PCB, and then the entire assembly is moved over the pool of solder where it encounters enough heat to melt several points of contact throughout each component. This process creates a reliable electrical connection which keeps all elements firmly attached to the board. The downside of this technique is that excessive amounts of solder can be left behind, leading to shorts and other problems.

In contrast, reflow soldering uses a more precise and controlled environment to join components with solder paste. Rather than a pool of molten solder, this process uses a surface-mount technology (SMT) machine which applies heat to the board in several stages and degrees. This allows for greater control over the application of heat and helps ensure that only the desired amount of solder is used, reducing the risk of shorts or other electrical issues. Additionally, it eliminates the need for a separate fluxing agent since the pre-applied paste itself acts as a flux.

Useful Video: What Is Reflow Soldering? | Soldering

Conclusion

Reflow soldering is an essential part of any electronics manufacturing process. It provides a reliable and quick way to join components together that would otherwise be impossible to do by hand. In this article, we have covered the basics of reflow soldering, including what it is and how it works. We have also looked at some of the key considerations when using a reflow oven such as temperature control, time control and safety precautions. With this knowledge, you can confidently set up your own reflow soldering station and start producing high-quality electronics assemblies with ease.

By following the basic steps outlined in this guide, you can ensure successful reflow soldering with minimal effort. As always, safety should be your top priority when handling electrical equipment—so remember to wear appropriate personal protective equipment and follow all manufacturer guidelines when performing reflow soldering. With proper care and attention, you’ll soon become a master of the reflow process!

Whether you are a hobbyist looking to build small projects or an engineer working in a professional environment, having a good understanding of what is involved in reflow soldering will help you achieve great results every time. So take some time to read up on the topic and get yourself familiarized with all the necessary steps. Happy soldering!

References

- https://www.twi-global.com/technical-knowledge/faqs/what-is-soldering

- https://www.candorind.com/what-is-reflow-soldering/

- https://www.surfacemountprocess.com/reflow-soldering-process.html

- https://www.electronicshub.org/reflow-soldering/

- https://www.allaboutcircuits.com/industry-articles/a-comparison-of-reflow-soldering-and-wave-soldering/

Leave a Reply