It can be used to fix things like cell phones, laptops, and tablets. The benefits of micro soldering are that it is a very precise way to fix electronics, and it can save you a lot of money in the long run. If your electronic device is damaged and needs repair, you should consider micro soldering as an option. In this article, we will discuss what micro soldering is, and we will answer some common questions about the process. We will also provide some tips on how to improve your results when using micro soldering techniques.

Soldering in General

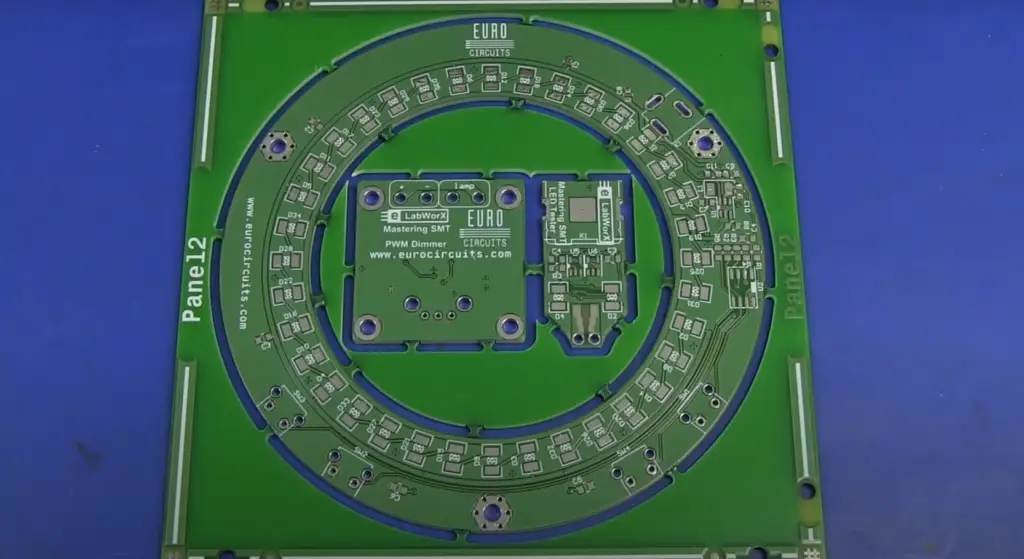

It is commonly used in electrical applications, such as creating circuit boards, attaching wires to machines, and repairing electronics like computers, smartphones, tablets, and other devices. In micro soldering, the process is scaled down to allow for small-scale soldering jobs. [1]

What Is Micro Soldering?

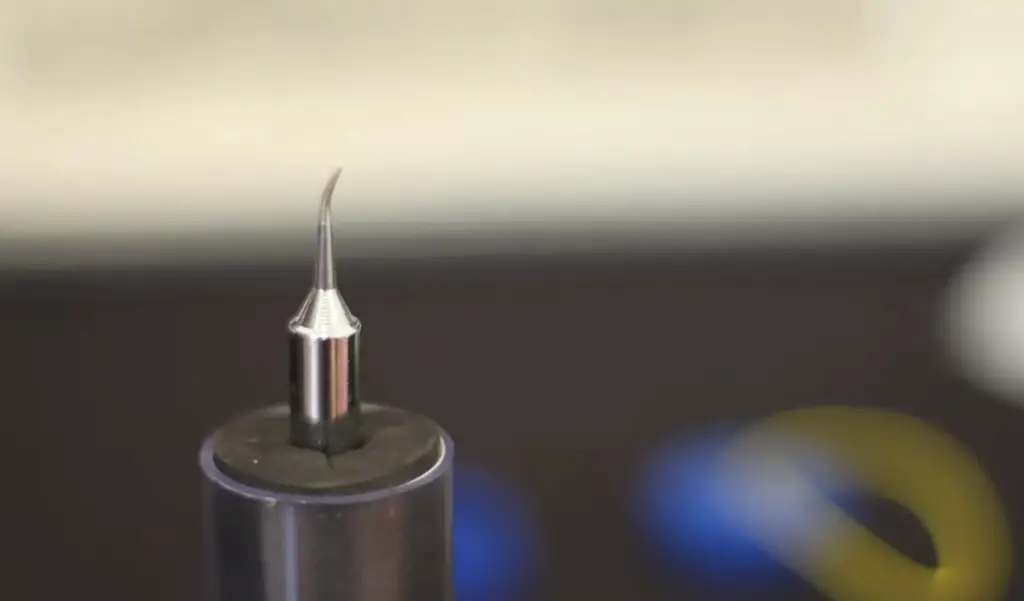

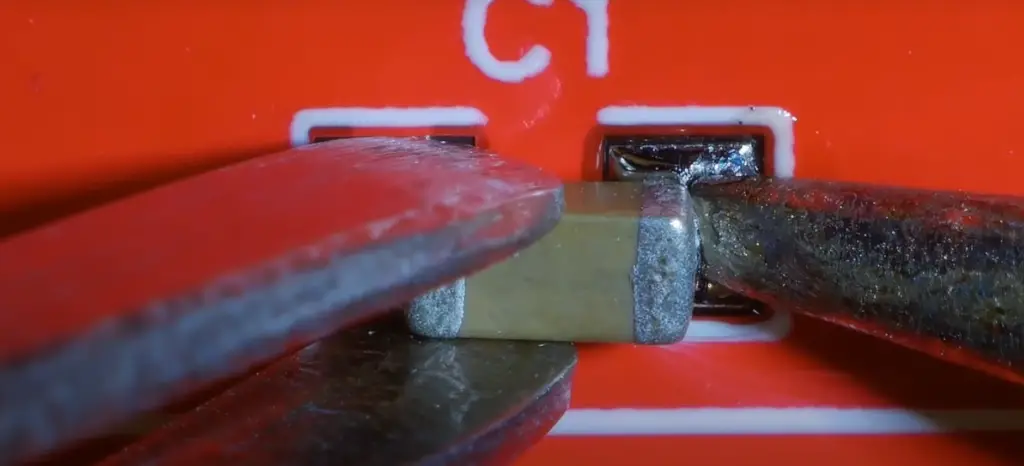

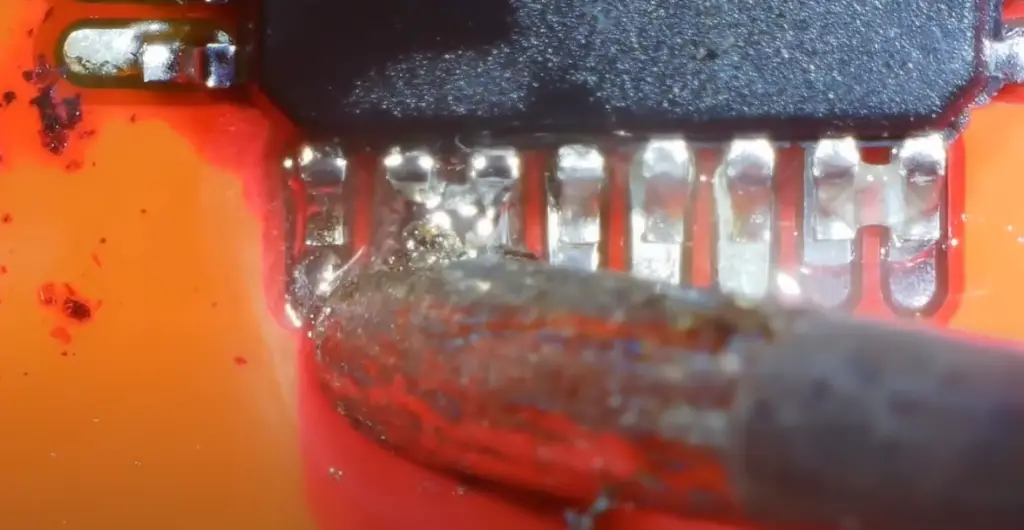

This type of soldering requires specialized tools, such as fine-tipped tweezers, an adjustable temperature soldering iron, flux, and solder wick (a type of conductive metal that removes unwanted solder). The process itself involves applying heat to the metal connections with the soldering iron while simultaneously feeding in new solder to create a reliable electrical connection.

Unlike traditional soldering — which often requires larger components and more power — micro soldering minimizes the amount of heat necessary for repair work. As a result, it can be used for delicate repairs on sensitive parts without damaging them or causing further harm. Additionally, micro soldering can be used to repair small parts of complex electronics, such as components within a smartphone or tablet. [2], [3], [4], [5]

Where is Micro Soldering Mainly Used

Micro soldering is mainly used for repairing and troubleshooting mobile devices such as smartphones, tablets, laptops, game consoles, and digital cameras. It is also used to repair small electronic components like circuit boards and connectors that are found in various household appliances. Some common repairs include replacing broken connectors or other parts on circuit boards which have been damaged due to water damage, physical damage, corrosion or heat exposure.

The process of micro soldering requires special tools and skills which makes it an appealing choice for hardware engineers who want to make sure their devices are properly repaired without causing any additional damage to the device itself. Using a high-quality micro soldering toolkit can help simplify the process while ensuring that your device is well taken care of. [2], [3], [4], [5]

Equipment Required for Micro Soldering

As we already explained, it requires extremely precise manipulation of tiny parts to ensure proper function. This makes micro soldering very different from regular soldering used for larger components. The process requires special tools and materials that are not commonly found in most households or repair shops.

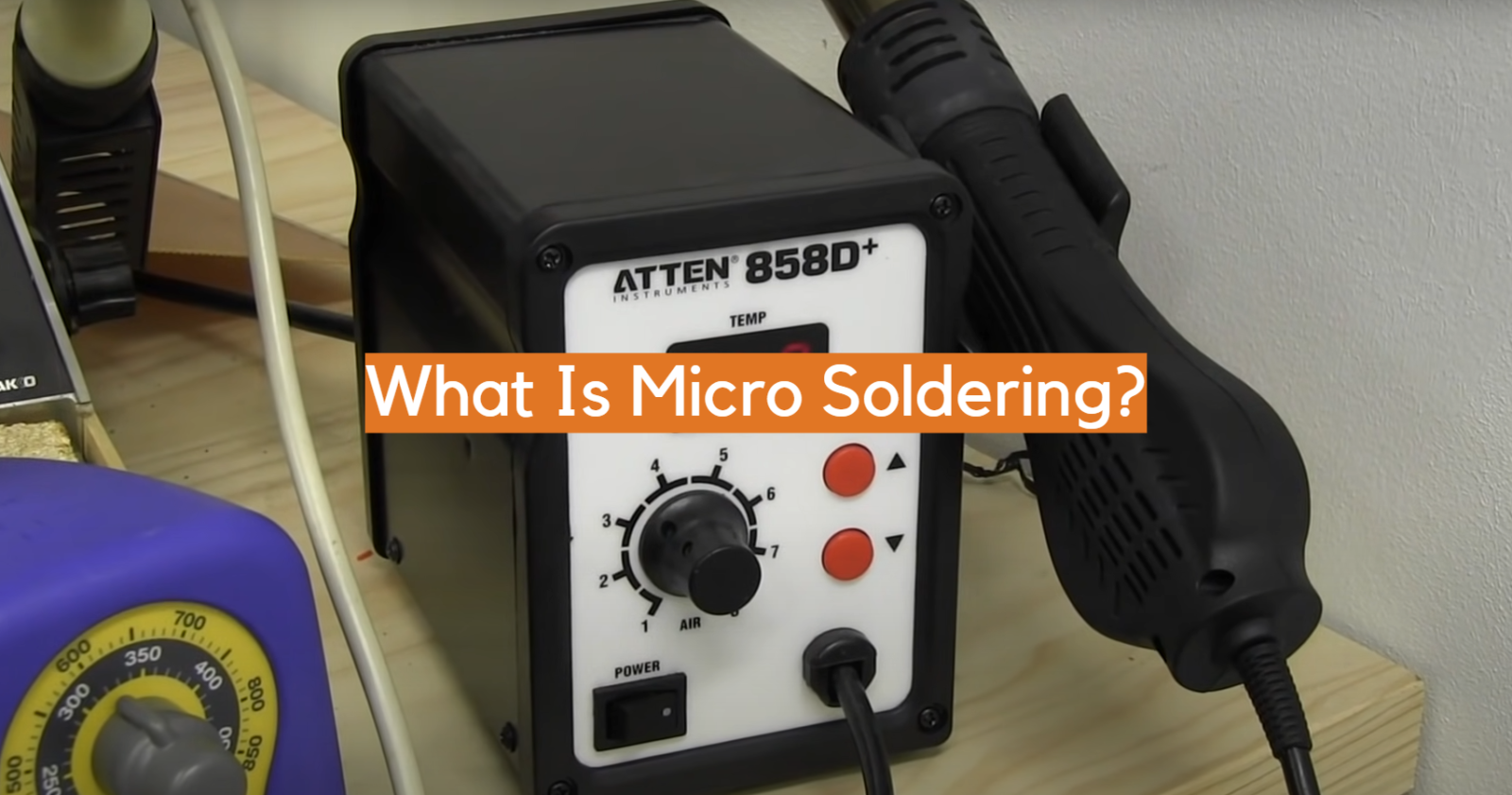

Micro soldering station

The most important piece of equipment used in micro soldering is a micro soldering station. This specialized device consists of a powerful magnifier, a soldering iron with interchangeable tips, adjustable heat settings and temperature control, and an anti-static work surface. It may also include additional features like air guns to keep your workspace clean. A good quality micro soldering station should last for many years with proper maintenance and care.

If you’re micro soldering in a professional setting, a specialized station is a must-have. It will not only improve your precision and accuracy, but also allow you to work faster and more efficiently.

Microsolder

A microsolder is a small filler material which is used to bond two conductive parts together. It is typically made from a combination of metals, including lead, tin and silver. The microsolder material comes in various forms such as wire or tape and must be carefully chosen for the specific application. Depending on the type of material being soldered, different microsolders will provide differing results in terms of strength and heat resistance.

Flux

Flux is a substance used in the soldering process to help with surface wetting and to remove oxides from solder joints. It is also used to prevent oxidation of the metal surfaces being joined during heating. Flux can be either an acid or a non-acid, depending on its composition. Non-acid fluxes are often referred to as Rosin-based fluxes and are most commonly used for electrical soldering due to their lower toxicity than acid fluxes. Acid-based fluxes are most suited for plumbing work because they dissolve away hard scale deposits that would otherwise prevent two pieces of metal from bonding together effectively.

Micro soldering requires an extremely high degree of accuracy when it comes to soldering components together. This is why flux is an important tool for micro soldering; its ability to remove oxide layers from the metal surfaces being joined helps make sure that the joint will properly form and remain secure with minimal effort on the part of the technician. Flux also aids in preventing oxidation during heating, which can result in a weaker joint if not taken into account.

In addition to providing a better bond between two pieces of metal, flux can also provide additional protection against electrical shorts or corrosion over time due to its ability to block air and moisture. It can also reduce thermal shock when used correctly, as it produces a lower heat margin than traditional solder.

Overall, flux plays an important role in any type of soldering, and micro soldering is no exception. Its ability to help form stronger bonds, reduce thermal shock, and provide additional protection against electrical shorts or corrosion make it an invaluable tool in the micro soldering process.

A microscope

A microscope is a very important tool for micro soldering. It provides the technician with detailed views of the components and allows them to make sure that each connection is secure and accurate. Microscopes can range in magnification a lot, although 0.5x-10x magnifiers are most commonly used for small repairs that require precision.

The use of a microscope is essential when it comes to micro soldering as it enables technicians to work quickly and accurately on even the smallest components. Without one, it would be difficult to perform any kind of repair or modification at this level. Aside from providing a clear view of what’s being worked on, microscopes also make it easier to spot flaws and imperfections in solder joints, helping to ensure a better quality result.

Heat gun

Heat guns come in various sizes and power ratings, so it’s important to choose one that is suitable for the type of job being done.

Before beginning a micro soldering process, it’s a good choice to heat all the components of the PCB evenly to ensure a good soldering experience. Heat guns help with this by allowing the technician to apply heat in a controlled manner, without having to rely on an oven or other heating device.

When used correctly, a heat gun can help speed up the micro soldering process while still providing enough precision and control over the temperature applied. When shopping for a heat gun, make sure to consider factors such as wattage (higher wattages provide more consistent temperatures), size (for larger or smaller components) and attachments (to increase its versatility). [2], [3]

Traditional Methods of Micro Soldering

Nowadays, micro soldering is performed using a range of specialized tools and techniques. In this section, we shall discuss the traditional methods of micro soldering, as well as their advantages and disadvantages.

Applying an external heat source to the joint

The most common way to perform micro soldering is by using an external heat source, such as a soldering iron or hot air gun, to apply heat to the joint and a filler material to form a bond. This method is typically used for surface-mount components, where the joint area is too small to be accessible with a soldering iron and the components need to be heated quickly. The key benefit of this approach is that it allows very precise control over the temperature and amount of heat applied, ensuring an optimal connection between the two parts. The downside, however, is that this technique can damage sensitive components if overheated or not handled correctly.

Welding using an electric current

Another common method for micro soldering is welding using an electric current. This technique relies on passing a small electrical current through the joint in order to melt it up and form a bond between the two parts. The advantages of this approach are that it can be used on larger components and that it does not require any manual intervention, as the process is controlled by the device itself. The downside, however, is that it requires specialized equipment and can potentially cause damage to nearby components if not handled correctly.

Thermo-pressure bonding

As you can see the above methods come with their own downsides, which is why there has been a growing demand for alternative methods of micro soldering. One such method is thermo-pressure bonding, which relies on the application of heat and pressure to form a bond between two parts. This technique can be used to solder small components, as well as larger ones. The key benefit it offers is that it rarely can cause damage to nearby components, thus making it far safer than traditional soldering methods. [4]

What Are the Benefits of Micro Soldering?

The primary benefit of micro soldering is its precision and reliability. By using smaller tools and applying less heat, it’s possible to make extremely precise repairs without risking damage to any other areas of the electronic device. This makes micro soldering an ideal option for delicate work on circuit boards and other sensitive devices. Additionally, because less heat is involved in the process, you don’t have to worry about damaging delicate components due to overheating them with traditional soldering techniques.

Micro soldering also offers cost savings compared to traditional methods since fewer materials are needed. Additionally, since it requires less time and expertise to perform, you can save money by hiring fewer technicians and having them complete more repairs in the same amount of time.

Finally, micro soldering is a great option for both DIY enthusiasts and repairers who want to repair their own electronics without risking damage or wasting too much money on supplies. By using smaller tools and applying less heat, it’s possible to make quality repairs without any specialized knowledge or skills. And you don’t need to replace your electronics either.

Overall, micro soldering offers many benefits over traditional techniques due to its precision, reliability, cost savings, and ease of use. It’s no wonder why this technique is becoming increasingly popular among electronic device owners! [2], [3], [4], [5]

FAQ

Is soldering hard to learn?

Soldering is a skill that may take some time to master, but it’s not particularly difficult. To get started, you’ll need a soldering iron and some solder. You’ll also want to have flux paste or liquid nearby for cleaning the surfaces of the components you’re working with and helping the solder stick better. Once you’ve got your supplies ready, practice on scrap materials to get comfortable with how your tools work before attempting any sensitive repairs.

Wires are a good place to start as they provide a stable surface for the iron and can be easily replaced if you make a mistake. As your skills improve, move on to more difficult components like ICs and connectors. With practice, you’ll eventually become comfortable with most soldering tasks.

Do you need flux to solder small wires?

Yes, flux is necessary to solder small components and wires as it helps create a stronger bond and reduce the chance of the connections becoming loose. In addition, flux cleans away any oxidation that may cause issues when soldering such small components. To achieve the best results when soldering with very small wires or components, use an appropriate grade of flux for the job and ensure that you apply enough heat to melt both the solder and flux together.

What do I need for micro soldering?

In order to perform micro soldering, you will need a few basic tools. This includes a soldering iron with a very small tip (or several tips depending on the size of work that needs to be done), microsolder, flux, tweezers and other specialized tools such as microscopes and magnifying glasses. You may also need some specialized cleaning supplies.

And of course – a micro soldering machine! All of these tools will help you to successfully perform micro soldering.

Is micro soldering hard?

Micro soldering is a delicate and intricate process that requires precision and attention to detail. It takes patience, practice, and specialized tools to master the skill of micro soldering. However, it can be satisfying when done correctly! With some knowledge of electronics and basic soldering techniques, anyone can become an expert in micro soldering.

What is a micro soldering station?

It is an invaluable tool for repair professionals working with small-scale electronics, such as smartphones and other handheld devices. The stations typically consist of a microscope, soldering iron, desoldering pump, flux pen or bottle, tweezers, suction cup, hot air gun and possibly a solder paste dispenser.

The key elements of the workstation are the soldering iron and microscope – both of which allow technicians to make accurate connections between tiny pins or wires. The microscopic view allows them to get a better control over the solder joint and reduce the risk of damaging sensitive components.

Useful Video: Introduction to Microsoldering with Jessa Jones

Conclusion

Micro soldering has become a popular option for electronic device repairs. It offers a cost-effective solution for repairing devices such as phones, tablets, and other small electronics. With the right tools and techniques, micro soldering can be used to repair even complex issues with precision and accuracy. While it requires some level of expertise, once you are familiar with the basics of micro soldering, you can use it to save time and money versus traditional repair methods. With the right tutorial and tips from professionals, anyone can learn how to properly perform micro soldering repairs.

In this article, we have provided an overview of what micro soldering is, discussed its benefits, and offered some tips on how to get started. We hope that this article has been a useful guide for anyone considering micro soldering as a repair solution. With the right knowledge and tools, you can take advantage of the many benefits of micro soldering.

By understanding what micro soldering is and its associated benefits, you will be able to decide if this type of repair is the best option for your device. With quality equipment, practice and patience, anyone can become an expert in micro soldering repairs. Ultimately, micro soldering offers a cost-effective solution for repairing electronic devices with precision that few other methods are capable of providing.

References

- https://www.twi-global.com/technical-knowledge/faqs/what-is-soldering

- https://www.electronicshub.org/micro-soldering/

- https://www.fixshop.eu/blog-new/what-microsoldering-and-what-equipment-do-you-need-it/

- https://benatav.com/what-is-micro-soldering/

- https://www.myphilliewireless.com/blog/2019/12/5/what-is-micro-soldering-and-when-is-it-helpful

Leave a Reply