Relays are essential components of most industrial and commercial equipment. Whether it’s an automobile starting system, a smartphone-controlled robot, or any kind of machinery that requires lots of electrical and electronic components to coordinate their activity, chances are there is a relay working in the background. But what exactly is a relay? In this blog post, we will explore how relays work and why they are so important for electrical systems. We’ll discuss where you can find them and provide technical information about the types available on the market today. By understanding relays more deeply you’ll be better able to assess whether they’re suitable for your projects or not!

What is a Relay?

Relays can be used to protect against overloads, start motor-driven applications, detect faults, and remotely control home automation devices. They are also often found in computer networks, allowing data to be sent from one device to another without direct contact. By using relays, complex processes can be automated and controlled with little effort. In addition, relays are cost-effective components that require minimal maintenance.

Therefore, they are widely used in automotive electronics, aerospace technology, industrial automation systems, computers and telecommunications systems around the world for efficient operation.

How a Relay Works?

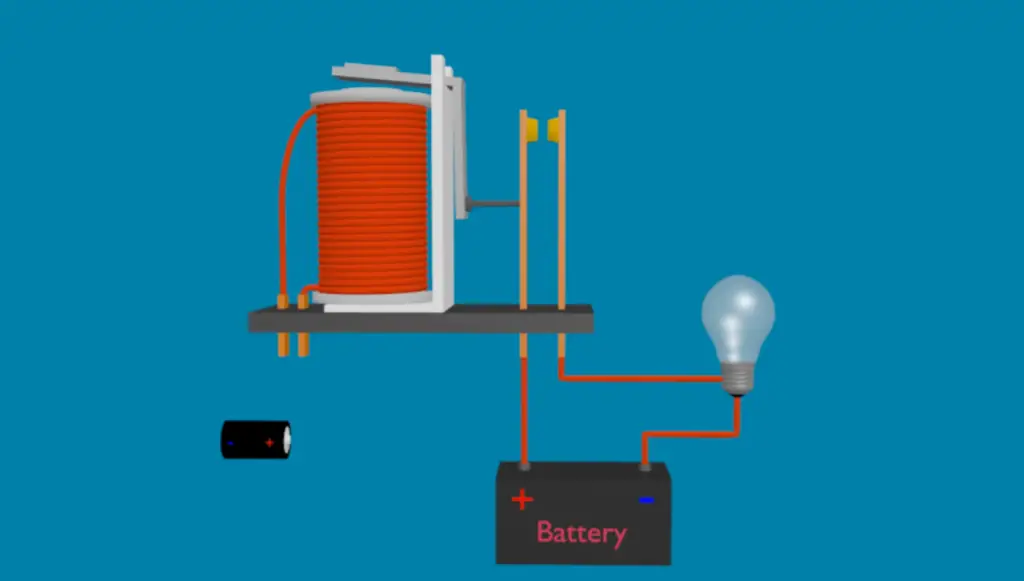

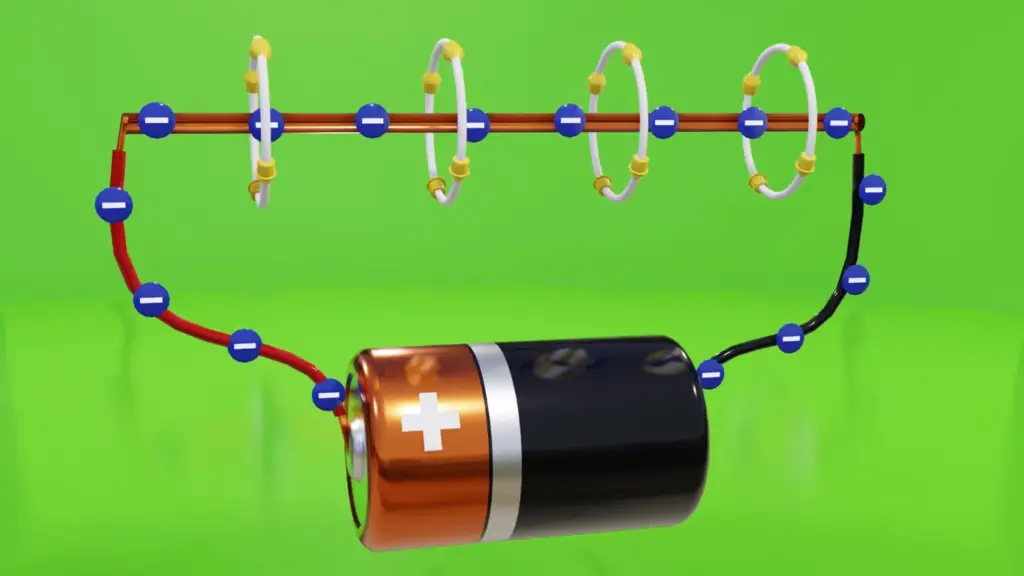

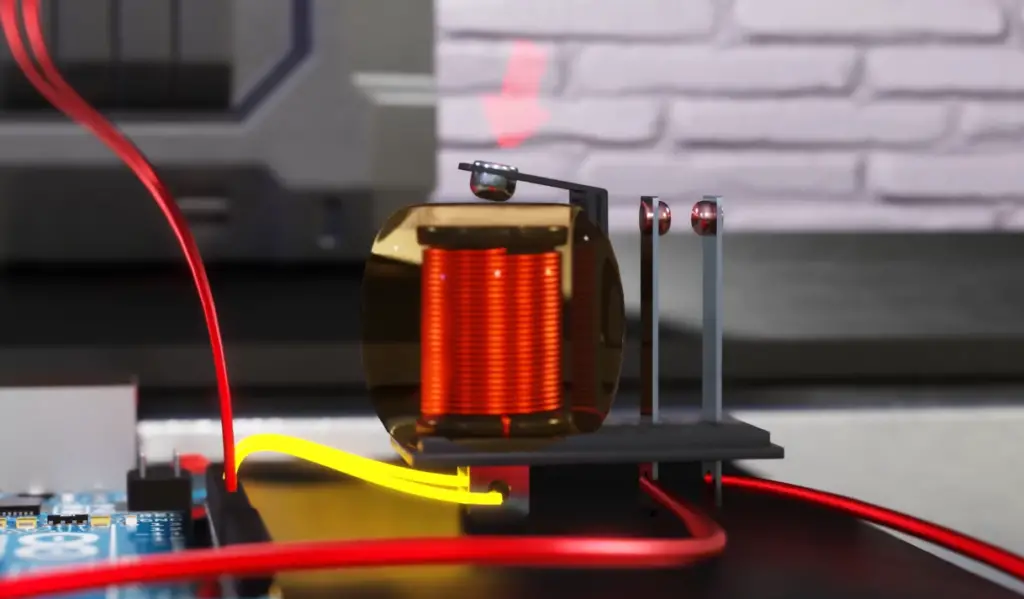

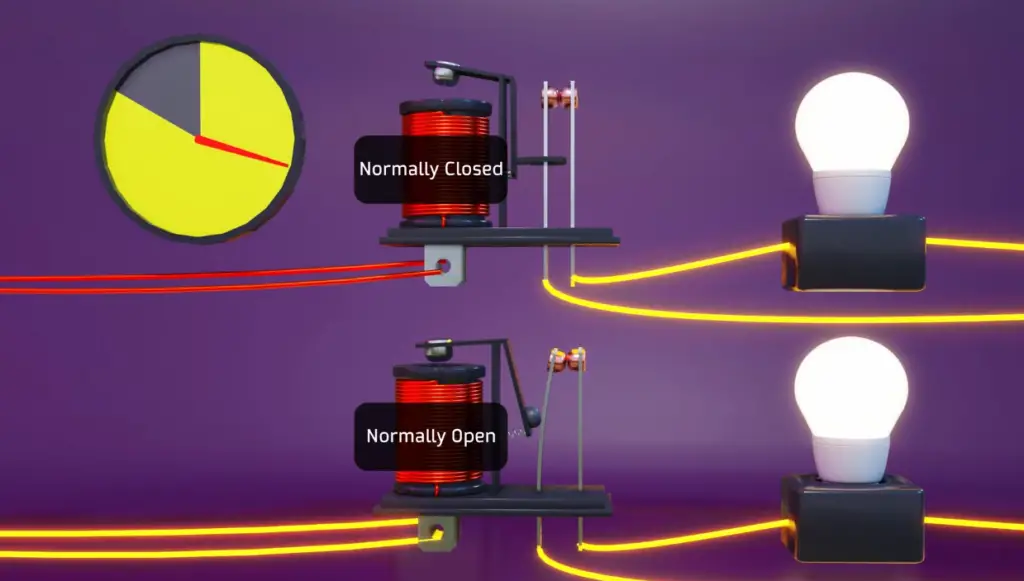

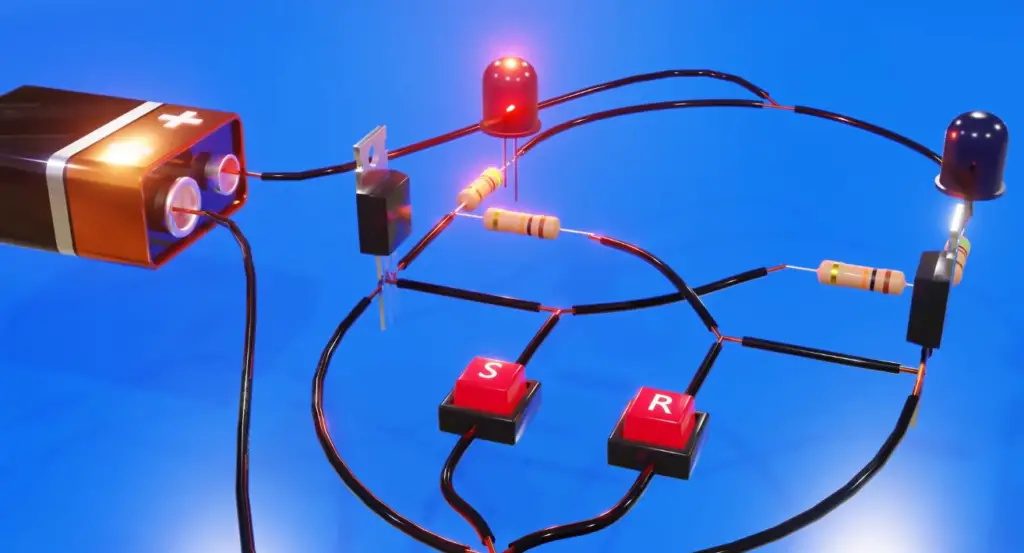

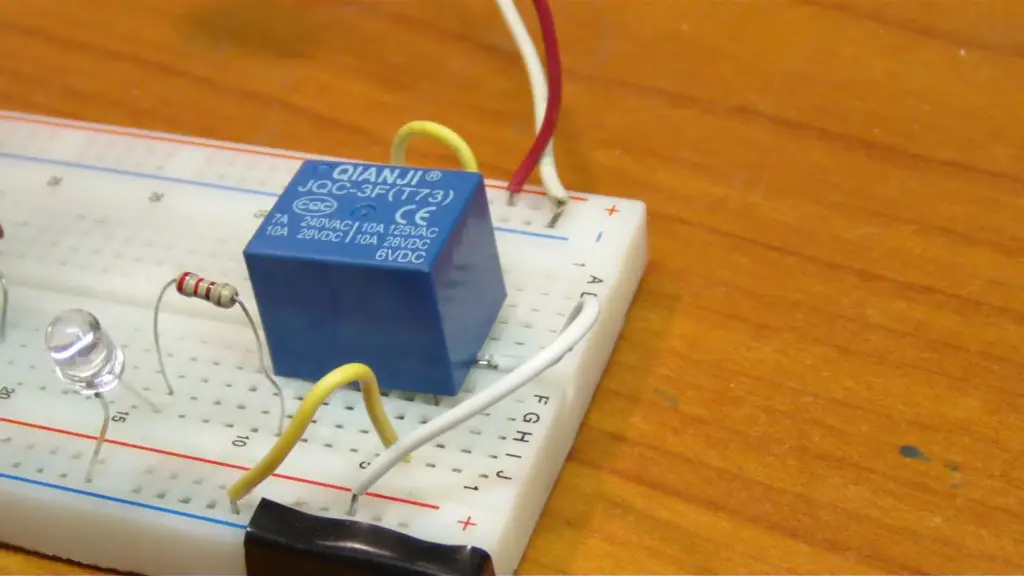

A relay is a switching device that works by energizing and de-energizing an electromagnet. When the electromagnet is energized, it attracts a switch and completes the circuit, allowing electricity to flow from one point to another. When the electromagnet is de-energized, it releases the switch and breaks the circuit, preventing electricity from flowing through. Relays can be used to control circuits with high voltages or currents, as well as for multiple applications such as switching lights on and off or controlling motors.

The most common type of relay uses an electromagnetic field to open and close contacts in order to control current flow in a circuit. In this type of relay, an electromagnet turns on when voltage is applied to it, which then causes a switch to close. This allows current to flow through the circuit and activate whatever device is connected. When the voltage is removed, the electromagnet turns off, which opens the switch and stops current from flowing.

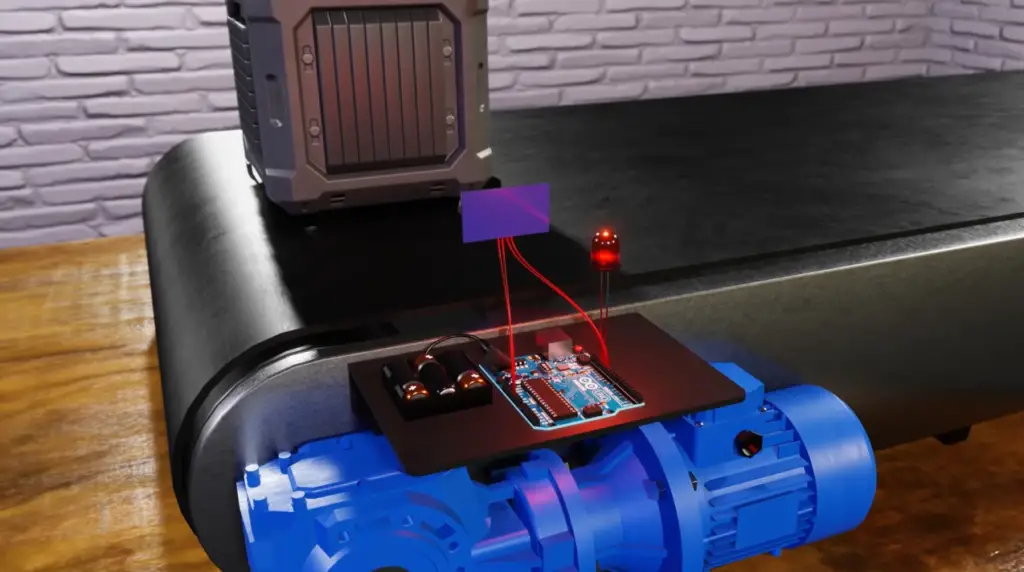

Relays are used in many applications such as industrial machinery, home appliances, automotive systems, robotics, medical equipment and security systems. They are designed to be reliable and durable with minimal wear over time. With their versatility and wide range of capabilities, relays are essential components in any circuit design. [1]

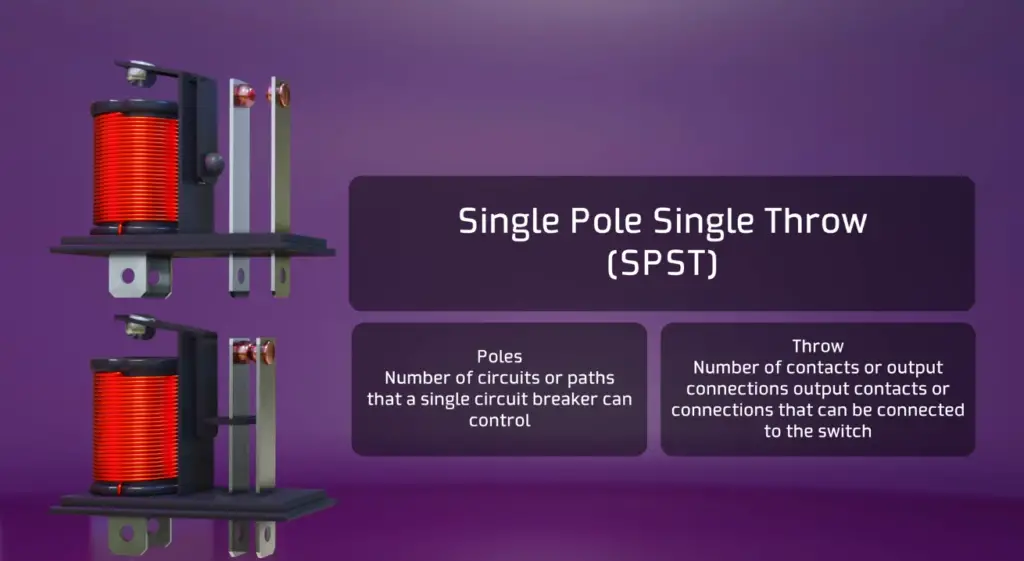

Relay Contact Types

Relays come in a variety of contact types, which are determined by the number of circuits and poles. The most common type is a single-pole double-throw (SPDT) relay, which has two circuits and one pole. This type allows for switching between two circuits. Double-pole double throw (DPDT) relays have two poles and four circuits, allowing for switching two separate circuits on or off simultaneously. A triple-pole double throw (3PDT) relay allows you to switch three separate circuits on or off at once, while a 4PDT relay can control four different circuits simultaneously. Additionally, latching relays require only one pulse of power to turn them on or off, making them useful in situations where power conservation is important.

Relay coils come in varying voltages, so it’s important to match the relay coil voltage with your application’s circuit requirements. In addition, many relays also have a maximum continuous current rating that should be taken into account when selecting and powering the relay for your application. Depending on the environment in which they are used, some relays may require hermetically sealed contacts or dust covers to ensure reliable operation and long life.

It’s also worth mentioning that relays can be combined to build more complex circuits, allowing for switching of multiple circuits at once.

By combining different contact types together, you can create relays that have multiple poles and multiple throws, giving you the ability to control many different circuits in your application. Relays are an essential part of any circuit, and understanding their types and applications can help you make informed decisions about how best to use them.

Types of Relays and Their Applications

Relays can be used for a variety of applications, ranging from controlling high-voltage circuits to regulating low-power signals. They are commonly used in automotive, industrial, and home electronics systems as well as in telecommunications. Common uses include switching on or off motors, lights, alarms and other devices.

The type of relay you choose should depend on the application’s requirements and the environment in which it will be used. For example, relays with hermetically sealed contacts may be needed if the device is operating in hazardous conditions. Additionally, dust covers may need to be considered for applications that operate in dusty areas.

When considering your options, remember to take into account the number of poles and throws, the coil voltage, and any other special requirements that your application may have. With the right type of relay, you can ensure reliable operation and long life for your device.

Overall, relays are simple yet powerful devices that allow you to control multiple circuits with one switch. Understanding their types, applications and features is essential in order to make the best choice for your application. By selecting the right relay for the job, you can be sure that your system will operate reliably and efficiently. [2]

Relay Applications

The versatility of relays allows them to be used in a wide variety of applications. Relays are utilized across many industries, from automotive and industrial automation to telecommunications and medical equipment. In the home, relay switches can be used for controlling lights, fans, pumps, garage doors, security systems, and more.

Industrial settings may call for larger power relays to control large motors and other heavy duty machinery that requires intense current flow. Automotive manufacturers use relays to control various electrical components in cars such as headlights, ignition systems, horns, wipers and other accessories.

Telecommunication networks often use multiplexer/demultiplexer relays which permit multiple signals to travel over a single line without interfering with each other. They are also used in audio and video broadcasting systems to effectively transmit signals from one point to another.

In the medical field, relays can be found in hospital equipment such as ventilators, infusion pumps, patient monitors, and more. Relays are often used to switch between different pieces of equipment or provide alarms and alerts when certain conditions have been met. This ensures that patients receive the proper care without any delays or dangerous mishaps occurring.

The various uses of relays make them essential components for many industries around the world. With their versatility and dependable performance, they will continue to play an important role in powering modern technology for years to come.

Contactors are still commonly used as relays in low power applications, especially for switching lights. The most common type of contactor is the electromagnetic relay and can be found in almost every home. They are typically used to control lighting circuits, motor circuits or to provide a safety interlock feature for larger equipment. These devices consist of an electromagnet and contacts which open and close as current passes through them.

In summary, relays are indispensable elements that allow us to automate different processes safely and reliably. They come in many forms from small contactors to large industrial power relays and can be found being used across many industries worldwide. Their essential functions make them vital components for our modern infrastructure. [3]

How to Test a Relay?

Here are some steps for testing a relay:

- Disconnect the power from the system that contains the relay, and then open up the system to gain access to the relay.

- Attach an ohmmeter or continuity tester between two of the terminals on the relay. If there is continuity, then the coil inside is working properly and sending electricity through its internal contacts.

- With an ohmmeter, measure resistance across all sets of points within the relay. This will tell you whether each set of contacts is open or closed.

- Test all the mechanical connections on the relay to make sure they are secure and that there is no corrosion or loose wires.

- Reconnect the power to the system that contains the relay, and then test it for proper operation by putting a load across the contacts of the relay. This will tell you whether there is sufficient current passing through them when power is applied.

By following these steps, you can ensure your relay is working properly before installing it in any electrical system. Doing so will reduce any potential problems down the line and help prevent costly repairs or replacements. With a little time and attention, testing a relay can help keep your circuits running safely and efficiently!

Why Use A Relay?

Relays are essential components in electrical circuitry when it comes to allowing current flow from one area to another. Unlike a simple switch, which can only turn on and off, relays provide greater control over the flow of current because they allow voltage control. This is especially useful when controlling large amounts of power or when wiring different parts of a circuit together. Relays also help prevent short circuits from occurring by providing protection against overloads. In summary, relays are versatile devices that give engineers more options and flexibility when building circuits. They have become an indispensable part of any electrical system.

When used correctly, relays have many advantages including energy efficiency, cost savings, safety, reliability and durability – making them an ideal choice for industrial and commercial applications. In addition, relays are easy to install and maintain, making them a no-brainer for any engineer looking to save time and money in their projects. Furthermore, the use of relays helps ensure that electrical systems comply with safety regulations while providing optimal performance. [4]

In short, when used correctly, relays are an ideal choice for a variety of different applications due to their versatility and energy efficiency. They offer engineers many advantages such as cost savings, safety protection, reliability and durability – all of which make them invaluable components in any electrical system. Therefore, it is important for engineers to familiarize themselves with the different types of relays available and how they can be utilized to maximize their project’s potential.

Switching Level Of Current

A relay is an electrical device that uses a small current to switch on and off a larger current. The switching level can be adjusted using the relay’s contact rating, allowing the user to control how much power is switched. It is like a light switch in that it starts or stops the flow of electricity through a device, but this process happens automatically when triggered by an outside source such as a control signal from another circuit, or from manual operation. This makes relays useful for regulating large amounts of power through industrial machinery. Relays are often used as safety devices since they allow you to remotely control large currents without actually having to touch them physically. They also provide isolation between two circuits, preventing unintentional interaction or damage between them.

Additionally, relays can be used to add logic and control to electronic circuits. They can be programmed to activate, deactivate, or change a circuit based on certain conditions such as temperature or voltage levels. This allows them to serve as the brains of an electronic system, sending signals from one part of a system to another in order to make decisions or regulate functions. [5]

Complex Applications and Devices Often Utilize Relays

In more complex applications, relays may be used to control electrical equipment. For example, a relay can be used to turn on or off an industrial machine such as a furnace or air conditioner. They can also be used in automatic systems such as sprinkler systems which can activate at certain times of the day based on sensors that detect moisture levels. Relays are commonly found in automobiles and other transportation vehicles to control fuel pumps, electric windows, lights, stereo equipment, and other devices.

In addition to controlling electrical current flow in these applications, relays are also used for safety reasons by providing circuit protection from overloads or short circuits. Automobile manufacturers often use them as fail-safe mechanisms to ensure that electrical systems shut down in the event of a power failure or system malfunction. In addition, relays can be used to transmit data over long distances, such as between two buildings or locations.

Overall, relays are an essential component for many complex applications and devices. They provide control and safety features for various types of equipment while also providing the ability to transmit data over longer distances than would otherwise be possible with alternative methods such as hard-wiring. Relays are a vital tool for any engineer who works on automated systems or those which require precise control over current flow and/or data transmission.

Benefits Of A Relay

Relays offer a variety of benefits that make them an essential part of many electrical systems. For example, they can be used to control large currents with small amounts of power, switch rapidly between two states, and provide protection for sensitive components. They also allow circuits to be separated from each other while still allowing data or signals to be transferred between them. This makes relays very useful for connecting multiple circuits together without having to physically interact with each circuit separately.

In addition, they are often used in automation processes as they can help improve the speed and accuracy of complex operations.

Finally, relays are relatively inexpensive and require minimal maintenance which makes them cost-effective options when compared to more complicated solutions such as programmable logic controllers (PLCs). This makes them ideal for use in low-cost applications where the cost and complexity of using a PLC is not necessary.

Overall, relays offer a wide range of advantages that make them indispensable components in many different types of electrical systems. They are highly reliable, can be used to control large currents with small amounts of power, switch rapidly between two states, provide protection for sensitive components, and allow multiple circuits to be connected together without physical interaction. They also offer excellent value for money as they require minimal maintenance and are relatively inexpensive compared to more complex solutions such as PLCs. As such, relays remain essential components within many electrical systems today. [6]

Drawbacks Of A Relay

Although relays offer many advantages, they also have some drawbacks. One of the major issues is that because of their simple construction, they can be vulnerable to electrical noise. This means that if there is a lot of electrical activity near the relay, it could cause problems in its operation. Additionally, relays are mechanical devices and therefore wear out over time which can lead to malfunction or failure. Lastly, because relays work by switching power on and off rapidly, they generate a buzzing sound when active which can be distracting in certain applications. Because of these disadvantages, other types of components such as transistors or contactors may be used instead of relays in certain situations.

Other disadvantages include size and complexity of wiring. As the current rating increases, the cost of relays also goes up. Also, due to their mechanical parts, they take up more space than other types of components. In addition, since multiple lines must be wired for each relay operation, relays can require a complex wiring setup which can increase costs and installation time.

How To Identify A Faulty Relay?

There are a few telltale signs that indicate when a relay is not functioning as intended:

- The relay does not click or anything else happens when power is applied to its electrical terminals.

- The current running through the contacts drops significantly when compared with what should be expected normally.

- There is visible damage on either side of the contact points, such as corrosion or melting due to excessive heat.

- The relay may have an unusual smell emanating from it, indicating burning or other malfunctions within its internal components.

- Lastly, the relay may begin to vibrate or shake excessively, which could indicate a mechanical fault.

If any of these symptoms are present, it’s best to replace the faulty unit with a new one and test its functionality accordingly. Knowing what to look for can help you identify a faulty relay quickly and easily before it causes further damage. [7]

What Is Inductor Flyback?

Inductor flyback is a type of relay that utilizes an inductor to store energy. This energy can then be tapped and directed towards the electrical load, allowing it to switch the current on and off quickly. In addition to switching, this type of relay also helps reduce voltage spikes and noise from the supply line by dissipating any excess energy when power is shut off. The switching action of an inductor flyback relay is often used in motor control applications, as well as in industrial automation systems for controlling valves or pumps. It’s important to note that while this type of relay can provide fast switching speeds, it requires more complex circuitry than other types of relays and consumes more power when activated.

Additionally, the inductor may generate heat due to the energy that is being dissipated, so it’s important to ensure that any inductor flyback relays are rated for the application they are used in. Properly designed and installed inductor flyback relays can provide reliable performance for many years and are often seen as a more reliable alternative to mechanical relays.

Overall, an inductor flyback relay is a specialized type of relay that utilizes an inductor to store energy and then direct it towards the load. Its fast switching speeds make it ideal for motor control applications while its ability to reduce voltage spikes and noise makes it valuable in industrial automation systems.

Why Do Relays Need A Transient Suppressor?

Relays are essential components in many electronic circuits, providing a way to control larger numbers of devices with smaller amounts of current. However, these devices can be susceptible to voltage transients and spikes that occur during normal operation – which can cause damage or malfunction if not addressed. As such, transient suppressors are necessary when using relays, to protect the device from any electrical noise or interference that could lead to costly repairs or replacements. Transient suppressors work by filtering out any unwanted signals or “noise” so they do not interfere with the relay’s operation.

In addition, they help ensure that the relay functions properly under all conditions, as some types of transients can switch the state of a relay even when no power is being applied. Without a transient suppressor in place, these brief spikes of power can cause the relay to unexpectedly switch states, potentially leading to short circuits or other electrical hazards. Thus, using a proper transient suppressor is essential for any application that uses relays and will help prevent costly damage or downtime due to voltage transients.

By filtering out unwanted noise and providing protection from voltage transients, transient suppressors are an important part of ensuring the safe and reliable operation of any device that utilizes relays. This simple safeguard can save time and money spent on repairs or replacements while helping ensure your equipment is always functioning at its best. By investing in a quality transient suppressor, you can make sure your device remains protected against unexpected surges in current.

The effectiveness of a transient suppressor will depend on the type and size chosen, as well as its placement in relation to the relay device itself. As such, it is important to consult with an expert when selecting a suppressor for your application in order to ensure you are getting the best protection possible. With the right transient suppressor in place, you can rest assured that your equipment will remain safe and reliable even during power fluctuations or surges. [8]

Where You Can Find Relays?

Relays are commonly used in everyday electrical circuits, such as those found in a home. When electricity is flowing through the circuit, it causes the relay to open and close its internal contacts. These contacts can then be used to control other parts of the circuit, such as turning on lights or even controlling an electric motor. Relays can also be found in many industrial settings where they are used to help automate processes or provide additional safety features for workers. They are also commonly found in automotive applications, such as controlling headlights, cooling fans, or even starting the engine.

In short, relays can be found almost anywhere there is an electrical circuit! Whether it’s a home, office building, or factory, there is usually at least one relay somewhere in the mix. They can be used for a variety of purposes, so if you ever need to control electricity in any way, relays are your best bet!

FAQ

What is the purpose of a relay?

The purpose of a relay is to allow a low-power signal to control an electrical device that requires a much larger voltage or current. A relay can be used to switch circuits on and off, protecting the original circuit from damage caused by excess power or current. Relays are mostly used in industrial and automotive applications, as well as for home security systems. They act as an intermediate between two electrical components, allowing them to communicate with each other without damaging either one.

What types of relays are there?

Relays come in many different shapes and sizes but they can generally be broken down into two main categories: mechanical and solid state relays. Mechanical relays consist of a coil of wire which creates an electromagnetic field when energized. This field attracts a moving armature within the relay, which then closes an internal switch. Solid state relays use semiconductor devices to control the electrical current instead of a mechanical mechanism, and are more efficient and reliable than their mechanical counterparts.

What is the difference between DC and AC relays?

DC (direct current) relays are used for applications that require low power switching, such as controlling small electronic components like LEDs. AC (alternating current) relays are designed to handle much higher voltages and currents, making them suitable for larger and more powerful devices such as motors or industrial machinery. AC relays usually have two sets of contacts which can be used in either normally open or normally closed positions.

When the relay is energized, the contacts will either open or close depending on which position is selected. AC relays are also available in two types: one pole and two pole. A one pole relay has only a single set of contacts while a two pole relay has two sets of contacts that can be connected or disconnected simultaneously.

What safety measures should be taken when working with relays?

When working with any type of electrical device, it’s important to take all necessary safety precautions. When dealing with relays specifically, make sure to never touch the terminals while they are energized as this could result in a severe electric shock. Additionally, make sure you always disconnect the power supply when making any repairs or modifications to the relay circuit. Finally, check that the relay is rated to handle the voltage and current of the device you are controlling before connecting it.

What is the difference between a switch and a relay?

The major difference between a switch and a relay is the way they control an electrical circuit. A switch simply opens or closes the circuit, while a relay uses electromagnetic induction to turn the circuit on and off. This allows for more complex control of the circuit, such as allowing devices in different parts of the building to control the same appliances from multiple locations. Additionally, relays can be used to automatically activate certain components when a certain condition is met, making them ideal for automation applications. In summary, switches are simpler and cheaper than relays but provide less versatility and automation capabilities. Relays require more advanced technology but allow for greater flexibility and automation potential.

What is a relay in a motor?

A relay in a motor is an electronic or electromechanical device that is used to control the flow of electricity within the motor. It does this by using its contacts to open and close circuit connections, thus allowing certain circuits to be powered on or off when required. Relays are typically used in motors with multiple speed settings, as well as those that use more complicated controls such as variable frequency drives. By using relays, these motors can be operated at different speeds or settings without having to manually adjust them each time. This makes them ideal for applications where frequent changes in speed may need to occur, such as with robotic machinery. In addition, most modern relays also offer protection features such as over-current and surge protection which further increase the motor’s overall reliability.

Is a relay a fuse?

No, a relay is not a fuse. A fuse is an electrical device that protects circuits from overcurrent and short circuits by breaking the circuit when too much current flows through it. A relay, on the other hand, is an electrically operated switch. It works by using an electromagnet to open or close one or more sets of contacts in another circuit. This allows a low-power signal to control a higher-power circuit (as well as isolating them). Relays are used in many different applications including things like controlling lighting, alarm systems, and motor controls. In modern vehicles, relays are even used to control things like the fuel pump and air conditioning compressor!

Can relay convert DC to AC?

No, a relay does not convert DC to AC. A relay is an electrically operated switch that can open or close one or more sets of contacts in another circuit. It uses an electromagnet to move the switch-like contacts, allowing a low-power signal to control a higher-power circuit (as well as isolating them). Relays cannot change the voltage or current type from DC to AC. To do this, you would need an electrical converter such as an inverter or transformer.

Useful Video: How a Relay Works – What is a Relay

Conclusion

A relay is an electrical device that allows low-voltage signals to control high-voltage circuits. These devices can help to increase safety and reduce the risk of electric shock when working with high voltages. Relays are found in many applications, from home automation systems to industrial machinery. Understanding how relays work and learning about the different types of relays available on the market can help you find the right solution for your needs.

Whether you’re looking for a simple solution or a more complex one, having a reliable relay in your system will ensure reliable operation and maximum safety. With this knowledge, you’ll be able to make an informed decision when selecting a relay for your project.

References

- https://www.electronicshub.org/what-is-relay-and-how-it-works/

- https://amperite.com/blog/relays/

- https://electrouniversity.com/what-is-a-relay/

- https://www.galco.com/comp/prod/relays.htm

- https://www.circuitbasics.com/what-is-a-relay/

- https://robocraze.com/blogs/post/what-is-relay-working-applications-types

- https://circuitdigest.com/article/relay-working-types-operation-applications

- https://theengineeringmindset.com/how-relays-work/

Leave a Reply