Weller 7200 soldering guns are quite popular. The smoking gun syndrome is their one downside. If your replacement tip was silver colored, it was probably copper tinned with solder. A little smoking is normal and the tinning will melt; however, if there is too much smoke, it indicates that the fuse has blown [1].

How to solve this problem? A few experts gathered their thoughts on this matter so you could repair and fix the problem of your Weller 7200 not getting hot after you turn it on. Following these steps should solve any issues with your Weller 7200 not getting hot enough to effectively solder. However, if there are still problems, contact customer service for further troubleshooting or potential defects with the soldering gun itself.

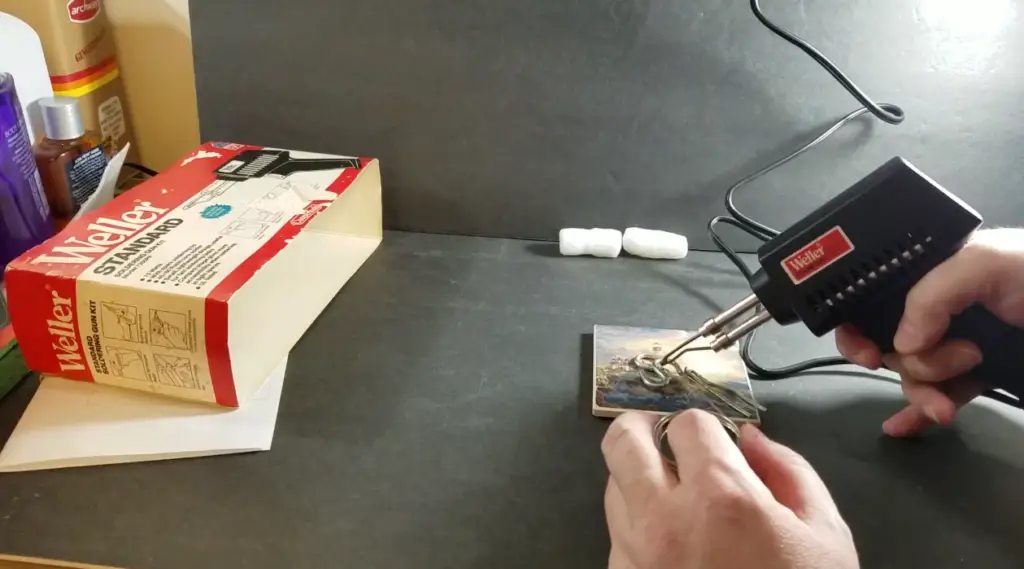

About Weller 7200 Soldering Gun

It features a copper burner type, a stainless steel heater design, and a comfortable fingertip trigger that makes it easy to use. The Weller 7200 also has a maximum temperature range of up to 900°F, making it ideal for soldering thicker wires.

The three 5mm high-temperature LEDs provide excellent illumination, and the co-molded soft grip ribbed handle design ensures that you have improved tip control and rotation. The Weller 7200 is UL listed and comes with a limited lifetime warranty [2].

It features a comfortable grip design that allows for increased control and precision, as well as a stainless steel heater for durability. The gun also has a built-in LED light that provides clear visibility while you work.

Specifications

- The weight is 1.5 pounds;

- The dimensions are 6 x 7.5 x 2 inches;

- The wattage is 75 Watts;

- The corded electric power source (the cord’s length is 5 feet);

- The copper burner type;

- Made with plastic;

- The frequency rating is 50/60 Hz;

- Limited lifetime warranty;

- Most kits include 2 soldering tips and a coil of lead-free solder;

- The maximum temperature range is up to 900°F;

- Three 5mm high-temperature LEDs at 25 lumens/ft²;

- The required voltage is 120 V;

- Co-molded soft grip ribbed handle design;

- Stainless steel heater design;

- UL listed;

Pros:

- Comfortable fingertip trigger;

- Reduced slippage;

- Improved tip control and rotation;

- High performance and accuracy;

- Nice illumination;

- Instant ready to solder within 6 seconds;

- Lightweight;

- Tin-plated;

- Budget-friendly;

- Requires little maintenance;

Cons:

- A loose connection from the coil to the probes is possible;

- Takes a long time to heat up thick wires;

- Long cool-off period;

This gun is made with high-quality materials and boasts a range of great features that make it perfect for anyone in need of a soldering gun. For example, the electric power source and cord length make it easy to use, while the copper burner type ensures that you get the perfect solder every time.

Additionally, the limited lifetime warranty is a great testimony to the quality of this gun. And if that wasn’t enough, the Weller 7200 Soldering Gun is also UL listed, meaning that it meets all safety standards.

How Does Soldering Iron’s Heating Element Wiring Work?

In understanding how to troubleshoot this issue, it’s important to first understand the basic wiring of a soldering iron’s heating element.

Most soldering irons have a power cord that enters the handle and connects to the tip. Inside the handle is a temperature control dial or circuit, which controls the flow of electricity through the heating element located in the tip [3].

When functioning properly, turning up the temperature will increase the flow of electricity through the heating element, causing it to become hot enough for the solder to melt onto connections.

Reasons Your Soldering Iron Isn’t Heating Up

- The temperature control may not be set high enough – turn up the temperature on your soldering iron and wait for it to fully heat up before use;

- The tip may not be making proper contact with the heating element – try cleaning or replacing the tip;

- The power cord or temperature control may have been damaged – if you suspect this is the case, stop using the soldering iron and seek professional repairs;

- The heating element itself may have malfunctioned – if this is the case, again stop using the soldering iron and seek professional repairs [4];

Steps To Follow When Fixing A Destroyed Soldering Iron

Do the basic checkup

First, check to make sure the soldering iron is plugged in and turned on. Next, check the temperature setting and adjust it if needed.

If the above steps do not solve the problem, try cleaning off any built-up residue on the tip of the iron with a damp sponge or steel wool.

If these steps do not work, it may be time to replace the heating element or the entire soldering iron.

Always remember to properly store your soldering iron when not in use to prevent damage and extend its lifespan.

Identify the destroyed parts

If the above steps do not solve the problem, it is time to inspect and identify any destroyed parts. This can include the heating element, thermocouple, or tip of the soldering iron.

Replacement parts can be purchased online or at hardware stores. Make sure to properly dispose of any damaged parts before installing new ones.

Always follow manufacturer instructions when replacing parts to ensure proper usage and safety.

Get the necessary materials and tools

Before starting any repairs, gather the necessary materials and tools such as a soldering iron, solder, replacement parts, screwdriver, pliers, and safety gear such as goggles and gloves. Make sure to work in a well-ventilated area to avoid inhaling any fumes or smoke produced by the soldering process [5].

Remove filament

Using the appropriate tools, carefully remove the damaged heating element or thermocouple from the soldering iron.

Install new filament

Following manufacturer instructions, properly install the new heating element or thermocouple into the soldering iron. Make sure all connections are secure and there are no loose wires.

Test the soldering iron

Before using the soldering iron, test it in a safe area to ensure it heats up properly and is ready for use. Always follow proper safety precautions when using a soldering iron.

If you encounter any issues during testing, double-check all connections and replace any damaged parts as needed.

If the issue persists, it may be time to seek professional assistance or consider purchasing a new soldering iron.

Do Soldering Irons Need Regular Maintenance?

Yes, soldering irons do require regular maintenance in order to keep them functioning properly. This includes cleaning the tips and replacing worn or damaged parts such as the heating element and power cord.

If your Weller 7200 soldering iron is not getting hot, first check that it is plugged in properly and receiving sufficient power. If those aspects are functioning correctly, then it may be time for some maintenance on the iron [6].

Start by scrubbing any built-up residue from the tip of the iron using a damp sponge or brass wire tip cleaner. Then, inspect the heating element for signs of damage or wear. Replace if necessary. It may also be a good idea to replace the power cord if it appears worn or frayed.

Soldering Iron Troubleshooting

First, check that your iron is plugged in and the outlet has power. If both are functioning properly, check the temperature setting on the iron. Make sure it is set to a high enough heat for soldering.

If the temperature is already set correctly, try cleaning the tip of the iron with a damp sponge or tip cleaner. A dirty or oxidized tip can affect heat transfer and prevent proper heating.

Most soldering irons use electricity. If the circuit is interrupted, then the flow of electricity will stop and the iron won’t produce any heat. The two most common reasons for a break in the circuit are a faulty connection in the iron or a heating element failure.

To figure out the issue, check the electrical connections as you take apart the soldering iron. They can come undone with age. Next, do a continuity test of the heating element to see if it’s still good.

If all of your electrical connections are good but you’re not registering any continuity, then you’ll need to replace your heating element. If the electrical connections are good and the heating element is registered with continuity, then your soldering iron may have a short and will likely need repairs.

However, if the heating element registers continuity and you noticed a loose or faulty connection during disassembly, simply secure the electrical and physical connections while reassembling your soldering iron – it should operate properly from that point on.

If these steps do not resolve the issue, it may be time to replace the heating element in your iron. Consult your manual for instructions on how to do this properly, or contact customer service for assistance [7].

FAQ

How do I reset my Weller 7200 soldering station?

To reset your soldering station, disconnect it from power and wait 5 seconds before plugging it back in. This should restart the system and allow you to make any necessary adjustments. If this does not work, contact customer service for further assistance [8].

How long does it take a Weller 7200 to heat up?

The Weller 7200PKS solders easily and efficiently, heating up in only 15 seconds – perfect for the hobbyist user [9]. However, the temperature and heating time may vary depending on what type of tip is being used. Consult your manual for more specific information on heat-up times for various tips.

Can I use my Weller 7200 with a different brand’s soldering tips?

Stick with Weller or any other compatible brands listed in your manual for the best results.

My Weller 7200 is heating up but not maintaining temperature. What could be causing this?

This could be a sign of a faulty thermostat or heating element. Try cleaning the tip of your iron with a damp sponge or tip cleaner as this can affect heat transfer. If that doesn’t resolve the issue, contact customer service for assistance in troubleshooting or replacing these parts if necessary.

How hot does the Weller soldering iron get?

Typically, the Weller 7200 soldering iron reaches temperatures up to 900 degrees Fahrenheit.

Is 25W enough for soldering iron?

If you’re only soldering two wires together, 25W is more than sufficient. In fact, after 5-10 minutes of use, the problem will be that the tip gets too hot and starts to oxidize excessively, which then causes it to overheat anything it meets. If it’s not doing that already, then there’s a good chance it’s broken [10].

How long does it take a 30-watt soldering iron to heat up?

On average, a 30-watt soldering iron takes about 1 to 2 minutes to heat up. However, this time can vary depending on the specific model and its temperature settings.

What temp does 60/40 solder melt?

The two most popular alloys for electrical soldering are 60/40 Sn-Pb and 63/37 Sn-Pb, which melt at 188°C (370 °F) and 153.7 °C (307.7°F) respectively [11].

What temperature should desoldering be?

To remove most surface-mount components, you must heat the entire component to a temperature that is high enough to melt the solder, but not so high or prolonged as to damage the component. For most purposes, a temperature up to 500 degrees Fahrenheit for 10 seconds is acceptable [12].

Why is tinning a soldering iron important?

Tinning a soldering iron helps to evenly distribute heat, improve the flow of solder, and prevent oxidation. Also, it helps to prolong the life of your soldering iron. When you tin your tips, you are essentially creating a barrier between the air and the iron that will in turn prevent oxidization.

This is important to do because if your tip isn’t tinned, it means that the process of oxidation is happening more rapidly. When heat isn’t being transferred efficiently, this causes issues with retaining heat in the soldering process [13].

What happens if you solder too hot?

If the temperature on your Weller 7200 soldering iron is set too high, it can lead to damaged components or burnt solder joints.

It can also cause damage to the soldering iron tip itself. Make sure that the temperature on your soldering iron is set correctly for the task at hand. Refer to your user manual for recommended temperatures for various types of solder and materials being worked on.

How do you solder metal at home

- Make sure your Weller 7200 soldering iron is plugged in and turned on;

- Check the temperature setting to ensure it is set to the appropriate level for your project;

- Apply flux to the area you want to solder;

- Touch the tip of the iron to the flux, then touch it to the metal pieces you want to join together;

- Press down gently and add a small amount of solder onto the joint;

- Allow enough time for the joint to cool before handling;

- If your Weller 7200 still isn’t getting hot, try changing the heating element or contacting customer support for further assistance;

What happens if you don’t clean the soldering iron?

When the soldering iron tip gets covered in oxides and burnt flux residues, the ability to transfer heat is significantly reduced. Not only does heat not travel as well through this debris, but the contaminants also prevent solder from wetting or sticking to the surface area of the tip.

How can you tell a cold solder joint?

A few indicators can point to a cold solder joint. First, the solder may appear dull or grainy instead of shiny. It may also have a bumpy texture instead of being smooth. Additionally, if the joint is disturbed, it may break apart easily.

How do you remove solder without heat?

Place the cold, flat-head screwdriver in contact with the liquid solder for a few seconds before removing it. If done correctly, the solder will adhere to the screwdriver and can be lifted from the surface.

Alternatively, using a soldering iron with adjustable temperature settings, lower the heat to its lowest setting and use that to gently remove the solder [14].

At what temperature does solder flow?

However, the exact melting temperature can vary depending on the specific type and composition of the solder being used. It is important to use a soldering iron with enough heat to properly melt the solder for successful joining or fixing of connections [15].

What solder has the highest melting point?

Zn/Al solder is ideal for those difficult-to-reach places or when you need a stronger hold because it has such a high melting point [16]. However, it is important to note that Zn/Al solder should not be used on aluminum or galvanized surfaces because it can lead to corrosion. Another option with a high melting point is indium solder, which is often used in electronics due to its low-temperature properties and ability to make strong bonds with various materials.

Is soldering iron smoke normal?

No, soldering iron smoke is not normal and can indicate a problem with your Weller 7200 or any other soldering iron.

First, check that the power cord is properly connected to both the wall outlet and the soldering iron base. If it is properly connected, try adjusting the temperature dial to see if that fixes the issue.

The joint where two pieces of metal are joined together by solder is called a brazed connection. Brazing is similar to welding but at lower temperatures. The most common type of brazing today uses an active metal filler that melts and flows into the space between two workpieces. Once cooled, the resulting connector has great pullout strength and other mechanical properties.

If adjusting the temperature and checking the power cord does not fix the issue, you may need to clean or replace the soldering iron tip. Over time, accumulated residue can prevent proper heat transfer, causing smoke and poor brazing results. To clean the tip, use a damp sponge or brass wool and gently wipe off any buildup. If cleaning does not resolve the issue, it may be time to purchase a new soldering iron tip.

If these steps do not solve the problem, it may be time to replace the heating element or contact Weller for repair options. Remember to always use appropriate ventilation when soldering to avoid inhaling harmful fumes.

What is the best wattage for soldering iron?

Typically, a soldering iron should have a wattage of between 20 and 40 watts for most small electronics soldering tasks. However, certain larger or more complicated projects may require a higher-wattage iron, such as the Weller 7200 with its 100-watt power [17].

What temperature does a 25-watt soldering iron get?

The average PCB soldering requires a 25-watt iron. If you use one with a higher wattage, you run the risk of melting the circuit board’s traces if you hold the iron in one spot for more than a second. For smaller projects, like SMT work, 15 watts will suffice. Generally speaking, though, 25 watts is plenty unless you are joining two large metal objects.

A 25-watt soldering iron can reach temperatures between 380° and 430° Celsius (716F – 806F) – slightly hotter than what 20-watt irons are capable of [18].

Useful Video: Restor , Repair , Renew old soldering gun Weller !

References

- https://www.rcgroups.com/forums/showthread.php?855788-Weller-7200-over-heating

- https://www.weller-tools.com/professional/usa/us/Weller+Consumer/Soldering+Guns/Soldering+Guns/7200PKS

- https://circuitbest.com/soldering-iron-not-heating/

- https://www.circuitspecialists.com/blog/soldering-iron-troubleshooting/

- https://circuitbest.com/soldering-iron-not-heating/

- https://dfarq.homeip.net/diy-weller-8200-soldering-gun-repair/

- https://www.circuitspecialists.com/blog/soldering-iron-troubleshooting/

- https://www.fixya.com/support/t12558976-need_instruction_manual_weller_7200

- https://www.homedepot.com/p/Weller-75-Watt-Soldering-Gun-Kit-7200PKS/100143633

- https://electronics.stackexchange.com/questions/23730/25-w-soldering-iron-not-working-properly

- https://en.wikipedia.org/wiki/Solder

- https://en.wikipedia.org/wiki/Desoldering

- https://www.weller-tools.com/how-to-care-for-soldering-iron-tips

- https://www.hunker.com/13417438/how-to-remove-solder-without-a-soldering-iron

- https://en.wikipedia.org/wiki/Solder

- https://www.globalspec.com/learnmore/manufacturing_process_equipment/welding_equipment_supplies/solder

- http://www.americanbeautytools.com/soldering/soldering-iron.html

- https://www.hellopractical.com/how-hot-does-a-soldering-iron-get/

Leave a Reply