A soldering gun is a handy tool to have in your arsenal, whether you are a professional or a DIY enthusiast. It can be used for many different projects, both big and small.

A soldering gun is a device with a metal point that gets extremely hot. We’re talking about 800 degrees Fahrenheit, but you can control the heat on a decent iron. Its function is to pass heat to wires, transistor leads, and PCB pads.

Solder is applied after the required regions have been properly heated. If you want to solder, invest in a 20- or 30-Watt soldering iron instead of a low-cost $15 one [1].

Benefits of Using A Soldering Iron:

- It is a very versatile tool;

- It can be used for a variety of purposes;

- It is a durable and reliable tool;

- It is an affordable device;

Types Of Soldering Equipment:

1) Soldering Guns

A soldering gun is the most powerful and quickest heating type of soldering device. It consists of a trigger-activated energy source, usually an electric heater, and a metal tip that gets very hot when power is applied to it. The heat generated by the gun melts the solder so that it can flow into the joint between two workpieces [2].

Advantages:

- The high power output of a soldering gun heats up the tip quickly, which is useful for joining heavy gauge wires together or working with large printed circuit boards;

- The quick heating time of the gun also makes it useful for soldering heat-sensitive components;

- The soldering gun can be used for a variety of tasks, including joining wires together, repairing printed circuit boards, and soldering heat-sensitive components;

Disadvantages:

- The large size and weight of a soldering gun can make it difficult to maneuver, especially in tight spaces;

- The high power output of the gun can also damage sensitive components if not used carefully;

- The concentrated heat of a soldering gun can damage sensitive electronic components and melt plastics. If not used carefully, they can also cause serious burns;

2) Soldering Irons

A soldering iron is a hand-held tool that consists of a heating element and a tip that gets very hot when power is applied to it. The heat generated by the iron melts the solder so that it can flow into the joint between two workpieces.

Advantages:

- Soldering irons are less likely to damage sensitive electronic components than soldering guns;

- The smaller size and weight of a soldering iron make it easier to maneuver, especially in tight spaces;

- The lower power output of a soldering iron prevents damage to sensitive components;

Disadvantages:

- Soldering irons take longer to heat up than soldering guns;

- The lower power output of a soldering iron can make it difficult to solder heavy gauge wires together or work with large printed circuit boards;

- The heat generated by a soldering iron can still damage sensitive electronic components and melt plastics. If not used carefully, they can also cause serious burns;

3) Desoldering Tools

Desoldering tools are used to remove solder from electronic components and printed circuit boards. There are two main types of desoldering tools: desoldering wicks and desoldering braid.

Desoldering wicks are made of braided copper wire that is coated with a flux-core solder. The wick is placed over the joint to be de-soldered and heated with a soldering iron until the solder melts. The wick absorbs the molten solder, leaving the joint clean.

Desoldering braid consists of fine strands of copper wire that are woven together. The braid is placed over the joint to be de-soldered and heated with a soldering iron until the solder melts. The heat causes the copper wires in the braid to expand, which pushes the molten solder out of the joint and onto the braid.

Advantages:

- Desoldering wicks and braid can be used to remove solder from a variety of electronic components;

- Desoldering wicks are less likely to damage sensitive electronic components than desoldering braid;

- Desoldering braid can be used to remove large amounts of solder quickly;

Disadvantages:

- Desoldering wicks and braids can be difficult to use in tight spaces;

- If not used carefully, desoldering wicks and braid can damage sensitive electronic components;

- Desoldering wicks and braids can be expensive;

Which type of soldering equipment is best for your project will depend on the materials you are working with and the level of precision you need. All types of soldering equipment have their advantages and disadvantages, so be sure to choose the one that will work best for your particular project.

What Is A Soldering Gun Used For?

A soldering gun is a powerful tool used for joining two pieces of metal together. It uses heat to melt the metal, which then flows into the joint and hardens, creating a strong bond.

A soldering gun is mostly applied for metalwork. Electricians frequently use soldering guns since they are useful for cable lugs and heavy-gauge wire.

How Do You Use A Soldering Gun:

1) Safety First

Before you start using your soldering gun, make sure to follow all the safety instructions that come with it. Most soldering guns will have a power switch and a temperature control knob. Make sure the power switch is turned off before you plug in the gun. Once it’s plugged in, turn on the power switch and set the temperature knob to the recommended setting [3].

2) Cleaning And Tinning The Tip

Once the gun is turned on and heated up, it’s time to clean and tin the tip. To clean the tip, simply wipe it off with a damp sponge.

Once it’s clean, apply a small amount of solder to the tip. This process is called tinning and it will help improve the conductivity of the soldering gun. Tinning also makes it easier to apply solder to your project.

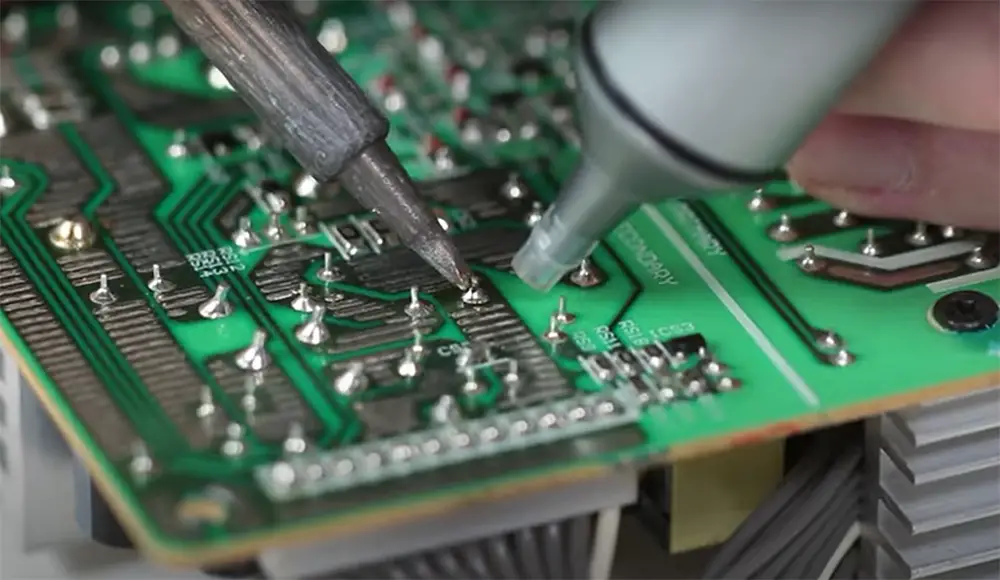

3) Joining Parts

Now it’s time to start soldering:

- Place the tip of the soldering gun on the joint between two parts;

- Apply a small amount of solder to the joint and allow it to flow into the gap;

- Once the solder has melted, remove the gun and allow the joint to cool;

Those are the basics of using a soldering gun. Just remember to always follow safety precautions and take your time. With a little practice, you’ll be able to master this useful tool in no time.

4) Desoldering

If you need to remove solder from a joint, you can do so by using the desoldering tip on your soldering gun. To use this tip, simply place it over the joint and heat it up. The solder should melt and flow out of the joint. Once the solder is removed, you can then clean up the area with a damp sponge [4].

FAQ:

What wattage of a soldering gun do you need?

If you enjoy soldering, a solder gun with a wattage range of 15 to 30 watts is ideal. However, high-wattage guns can harm certain components [5]. As a beginner, you might want to purchase a low-wattage gun and then upgrade as you get more comfortable with the hobby.

When did the soldering gun originate?

In 1941, Carl E. Weller created and later obtained a transformer-based soldering tool that heated and cooled rapidly, as described in this post. In 1946, Weller established a business to make and market his invention on a commercial scale [6].

What safety precautions do you need to take when using a soldering gun?

When using a soldering gun, it is important to take proper safety precautions.

Always wear gloves and eye protection when using a soldering gun. Additionally, be sure to keep the tip of the gun clean and free of debris. Finally, always unplug the soldering gun when you are finished using it.

By following these simple safety tips, you can ensure that you will have a safe and successful experience when using a soldering gun:

- Don’t overheat the components. This can damage them beyond repair;

- Have good ventilation in the room where you work. Soldering produces harmful fumes, so it’s important to work in a well-ventilated area;

- Don’t touch the hot tip of the gun. This can cause serious burns;

- Be careful not to get solder on your skin. If this happens, immediately wash the area with soap and water;

Who makes the best soldering guns?

This is a difficult question to answer. There are many brands of soldering guns on the market, and each has its own strengths and weaknesses. Some brands are better than others, but there is no definitive answer as to who makes the best soldering gun. Ultimately, it depends on the individual’s needs and preferences. The most well-known brands are Weller, Wall Lenk, Hakko, and Dorman.

At what temperature should I solder?

The soldering gun should be set to a temperature that is hot enough to melt the solder, but not so hot, that it damages the components. The ideal temperature for most soldering applications is somewhere between 650 and 850 degrees Fahrenheit [7].

You can test the temperature of the tip by touching it to a piece of scrap metal. If the metal turns red, then the tip is too hot and needs to be cooled down before continuing.

What kind of solder should I use?

There are 2 types of solder that you can use for soldering [8]:

- Lead-based solder has a lower melting point<, so it’s easier to work with. However, it’s not as safe to use because the lead can be harmful if ingested;

- Lead-free solder has a higher melting point, so it’s more difficult to work with. However, it’s much safer to use because there is no lead in it;

When choosing a type of solder, you should also consider what you’ll be using it for.

If you’re going to be working with electronic components, then you should use lead-free solder.

If you’re just going to be soldering metal pipes together, then you can use either lead-based or lead-free solder.

How can I make soldering easier?

If you’re just starting out, the biggest challenge can be getting the solder to flow onto the joint. Here are a few tips:

- Use a small amount of solder. Too much can make it difficult to heat the joint evenly, and can also lead to messy joints;

- Apply flux to the joints before soldering. This will help the solder flow more easily;

- Use a needle tip or conical tip on your soldering gun. This will help concentrate the heat on the joint and make it easier to control;

How is a soldering station different?

A soldering station includes a power unit with adjustable temperature control and a hot iron. This type of device is generally used in professional applications, as it provides more precise temperature control than a soldering gun.

A soldering station also typically has a stand to hold the hot iron when not in use, as well as a sponge or other material to clean the tip of the iron.

If you’re just starting out, however, a soldering gun may be all you need. These units are less expensive than soldering stations, and they’re easier to use since they don’t require any temperature adjustment. Just plug in the gun, wait for it to heat up, and start soldering!

How do you solder for beginners?

If you’re a beginner, the best way to start soldering is by using a soldering gun. A soldering gun is a hand-held tool that uses electricity to heat up the tip of the gun, which in turn melts the solder.

To use a soldering gun:

- First, make sure that the area you’re working in is well-ventilated. Solder contains lead, which can be harmful if inhaled;

- Next, plug in your soldering gun and let it heat up for a few minutes. While you’re waiting, gather all of your materials together. You’ll need solder, flux (a substance that helps the solder flow and adhere to the surface), and something to clean the tip of the gun with (like a sponge);

- Once the gun is heated up, touch the tip to the area you want to solder and apply flux. Then, touch the end of the solder to the joint and let it flow into place;

- Finally, remove the soldering gun and let the area cool. Once it’s cooled, you can use a cloth or brush to remove any excess flux;

What is the difference between a soldering iron and a soldering gun?

A soldering gun is a small, handheld device that resembles a pistol and is utilized to join metal surfaces with one hand. The wand-shaped soldering iron has a heated metal tip and is used to connect two metals together [9].

The main difference between a soldering iron and a soldering gun is that the soldering gun has a much higher wattage than the soldering iron. This results in the tip of the gun being able to heat up faster, making it ideal for quick jobs.

Do I need flux to solder?

If you are soldering two pieces of metal together, then you will need to use flux. This is because the flux helps to clean the surface of the metal and also prevents oxidation.

You can buy flux in a variety of forms, including liquid, paste, or powder. You will also need to choose the right type of flux for the job. For example, there are different types of flux for soldering copper and aluminum.

Once you have your flux, apply it to the surface of the metal that you are going to solder. Then heat up your soldering gun and touch the tip to the area where you applied the flux. The heat from the gun will melt the flux and help to clean the surface of the metal.

Are soldering guns useful?

Yes, soldering guns are useful tools that can be used for a variety of purposes. For example, soldering guns can be used to repair electrical components or to attach two pieces of metal together.

Soldering guns typically have a metal tip that gets very hot when the gun is turned on. This allows the user to melt the solder, which is then used to join two pieces of metal together.

When should I use a soldering gun?

There are a few different situations when you might need to use a soldering gun. For example, you might need to use a soldering gun if you’re repairing an electrical component or attaching two pieces of metal together.

In general, soldering guns are best for larger projects where you need to join two thick pieces of metal together. If you’re just trying to repair a small electrical component, then you might be better off using a smaller soldering iron instead.

Useful Video: How to Use a Soldering Gun : Lawn Care & Power Tools

References:

- https://www.howtogeek.com/63630/how-to-use-a-soldering-iron-a-beginners-guide/

- https://www.journeymanhq.com/2142/soldering-gun-product-guide/

- https://www.howtogeek.com/63630/how-to-use-a-soldering-iron-a-beginners-guide/

- https://www.weller-tools.com/how-to-use-soldering-iron/

- http://www.americanbeautytools.com/soldering/solder-gun.html

- https://en.wikipedia.org/wiki/Soldering_gun

- https://www.techspray.com/ultimate-guide-to-electronic-soldering

- https://www.makerspaces.com/how-to-solder

- https://www.circuitspecialists.com/soldering-gun-vs-soldering-iron

Personally, desoldering wicks stand out as effective tools for meticulous solder removal. Their braided copper wire, coated with flux-core solder, simplifies the process. When heated with a soldering iron, the wick skillfully absorbs molten solder, ensuring precision and cleanliness in desoldering electronic components and printed circuit boards.

Personally, desoldering wicks stand out as effective tools for meticulous solder removal. Their braided copper wire, coated with flux-core solder, simplifies the process. When heated with a soldering iron, the wick skillfully absorbs molten solder, ensuring precision and cleanliness in desoldering electronic components and printed circuit boards.

Leave a Reply