Are you curious about the different fuse types available to protect your electrical system? Well then, you’ve come to the right place! Fuses are an essential component of any electrical system and selecting the correct type is critical for ensuring a safe power distribution. We believe that knowledge is power and understanding what each type of fuse has to offer can help prevent potential damage from occurring. This blog post will discuss various common fuse types and their best applications so that anyone who needs to identify the ideal type for their project can do so confidently!

What is a Fuse?

Construction & Working of a Fuse

To safeguard your electrical circuits from overloads, a fuse is an essential safety device. This efficient tool can protect against power surges or shorts and prevent costly damage to the circuit board. It works by interrupting the flow of electricity when it becomes too high, thus preventing overloads and other potentially dangerous conditions.

Fuses are made up of two components: a fusible metal element and a housing. The metal element, usually composed of alloy or wire, has a lower melting point than the normal operating temperature of the circuit it’s protecting. When an excess current flows through the element, it melts and breaks the circuit, thereby protecting equipment from being destroyed. The housing typically consists of ceramic or plastic material that serves as a way to contain the melted fusible element once it has been triggered.

Fuses come in various types and ratings, depending on the amount of current and voltage they are designed to protect. Generally speaking, fuses are available from 0.5A to 600A and can be tailor-made for specific applications if needed.

When working with a fuse, it is important to pay attention to its rating and make sure that it is appropriate for the circuit that you’re connecting it to. If the fuse has too low of a rating, then the excess current will not be interrupted properly, while if it is too high then there is a risk that it will trip prematurely. Additionally, when selecting a new fuse, always ensure that it has an identical rating as the existing one. [1]

How to Select Proper Rating Size of Fuse?

The proper rating size of a fuse must be carefully selected to ensure the safety of an electrical system. The correct size allows the fuse to react in a timely manner and prevent electrical equipment from being damaged due to excessive amounts of current passing through it. The fuse must also be able to adequately carry all the load current (amps) needed, while not tripping prematurely due to transient surges or other temporary overloads.

To ensure the most accurate rating size of a fuse, one must take several elements into consideration, such as:

- The full-load amps (FLA) for each piece of equipment or accessory connected in the circuit

- The ambient temperature around the components and wiring

- Any available short-circuit protection devices or ground-fault interrupters

- The type of fuse used, which is based on the voltage and current rating of the system.

For more complex systems, ampacity tables may be used to select a fuse size for specific overcurrent protection requirements. Ampacity tables provide recommended ratings for fuse sizes that can safely carry certain levels of load current at different ambient temperatures.

It is important to note that if any changes are made in the circuit, such as increasing the number of circuit components or changing out existing components with ones with higher FLA ratings, then all associated fuse ratings must also be adjusted accordingly. Ultimately, selecting the proper rating size of a fuse will ensure maximum safety and performance within an electrical system. [2]

Characteristics of a Fuse

A fuse is a device that is designed to protect electrical circuits from being damaged by too much current flow. Fuses are typically composed of a metal strip or wire that has been heated and weakened so as to break when an overload occurs. The presence of a fuse in an electrical circuit helps ensure the safety of its users and equipment connected to it.

Fuses come in different types, each designed for specific applications and environments.

Fuse Current Carrying Capacity

This capacity is determined by the type of fuse, its size, and the voltage it is designed to work with. Standard fuses such as HRC (High Rupture Capacity) or HBC (High Breaking Capacity) are rated for 230V or 400V while higher specification fuses like FWP (Fuse Wire Protection) have a much greater current rating up to 690 V.

A general rule of thumb when selecting a fuse size is to choose one which has at least twice the nominal current rating compared to the load requirement. This will ensure that there is enough safety margin even if an unexpected surge in current occurs due to any unexpected fault or overload. It is important to note that using a fuse with too high of a current rating can create problems and risks such as overheating, blown connections, or other safety hazards.

I2t Value of Fuse

All fuses have an I2t value which is a measure of their ability to respond quickly in the event of an overload.

This indicates how much current can pass through the fuse over a short period of time, usually measured in milliseconds.

Generally speaking, the lower the I2t value, the better protection a fuse can offer against faults and surges. Fuses with higher I2t values are best suited for applications where there will be frequent start-up or shutdown periods with varying current demands. Low I2t values provide more reliable and consistent protection against excessive currents caused by equipment malfunctions or power supply disturbances. [3]

Response Characteristic of a Fuse

The response characteristic of a fuse is the speed at which it opens when current passes through it. In general, fast-acting fuses will open quickly in the event of an overload or short circuit while slow-blow fuses are designed to remain closed until a sustained overload occurs. Fast acting fuses are generally used for circuits with inductive loads such as motors and transformers, while slow-blow fuses are better suited for circuits with higher resistance loads such as heaters and fans. It’s important to select the correct type of fuse for each application to ensure that your equipment is well protected. Fuse response characteristics can be further broken down into time-delay characteristics:

- Very Fast Acting Fuses open quickly in the event of a short circuit and are suitable for high-peak current applications.

- Fast Acting Fuses provide a slightly delayed response, allowing momentary overloads to pass without causing damage.

- Slow Blow (Time Delay) Fuses provide additional time delay, allowing sustained overloads to pass without opening the circuit.

- Extremely Slow Blow (Delayed Action) Fuses have the highest time delay of all, making them ideal for circuits with large capacitive loads or slow ramping applications.

It’s important to select the appropriate fuse type for your application as different characteristics will respond differently depending on load type, duration and intensity of fault conditions.

Packaging Size

The size of the fuse is an important consideration when selecting the type and model for a particular application. Fuse sizes range from small, subminiature models to large fuses capable of handling hundreds of amps. Generally, larger fuses are either cylindrical or rectangular in shape, while smaller fuses may be flat pieces referred to as “blade” or “pig-tail” types. The size and shape of the fuse must match the opening provided in the equipment it is being installed into.

Additionally, some applications require that a certain amount of space be reserved around the fuse for insulation. If space limitations exist, smaller packages such as blade or pig-tail fuses should be considered first before looking at larger cylindrical or rectangular models. This is especially true when designing equipment that needs to be placed in cramped spaces such as in control panels, behind dashboards, and other confined areas. [4]

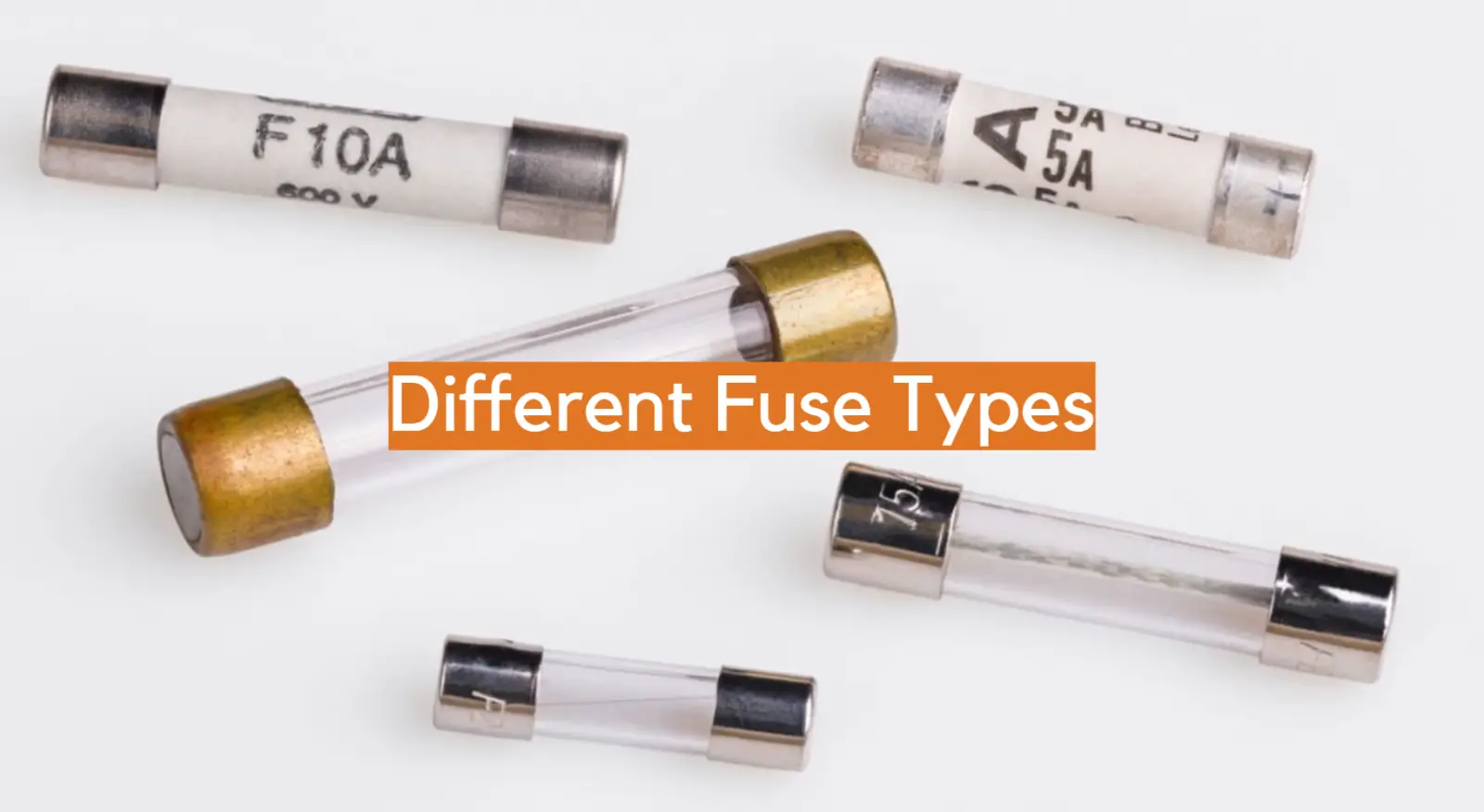

Types of Fuses

DC Fuse

DC fuses are also known as low voltage fuse, which is used to protect the electrical circuits from overvoltage conditions as well as short-circuiting. These current limiting devices can be found in automotive, electronic and telecommunications applications. They are considered a reliable form of protection for DC systems due to their ability to blow quickly with minimal arcing or sparking.

AC Fuse

An AC fuse is designed to react much faster than a DC fuse when exposed to an overload or short circuit condition. This type of fuse utilizes an interruption device that opens very quickly upon detecting an overcurrent situation, reducing the risk of damaging equipment by cutting off the power supply immediately. AC fuses are typically used in residential and commercial settings and include time-delay, high interrupting capacity, and motor protection fuses.

Low Voltage Electrical Fuse

This type of fuse is the most common and widely used. It is usually found in homes, offices, factories, etc., to protect electric circuits from overloads. Low voltage fuses are made from a variety of materials such as copper, aluminum, brass and stainless steel. They work by creating an open circuit when current levels exceed the rated capacity of the fuse. The current flow then stops until the overload is removed or replaced with a new low voltage fuse.

High Voltage Electrical Fuse

High voltage electrical fuses are found in power plants, transmission lines and other high-voltage applications. They are designed to protect against large surges and currents that could cause damage or destruction to equipment. Like low voltage fuses, they work by creating an open circuit when current levels exceed the rated capacity of the fuse.

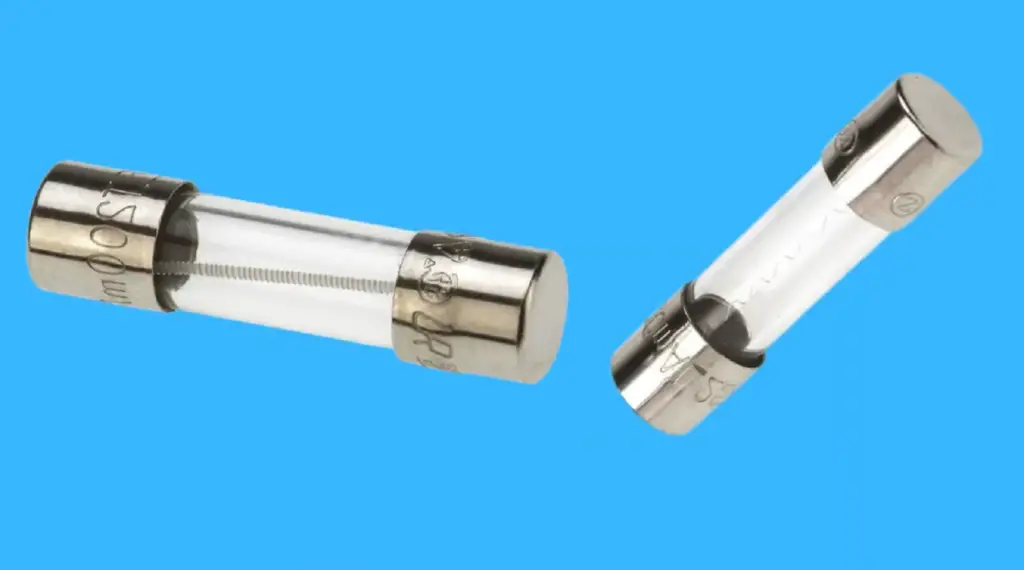

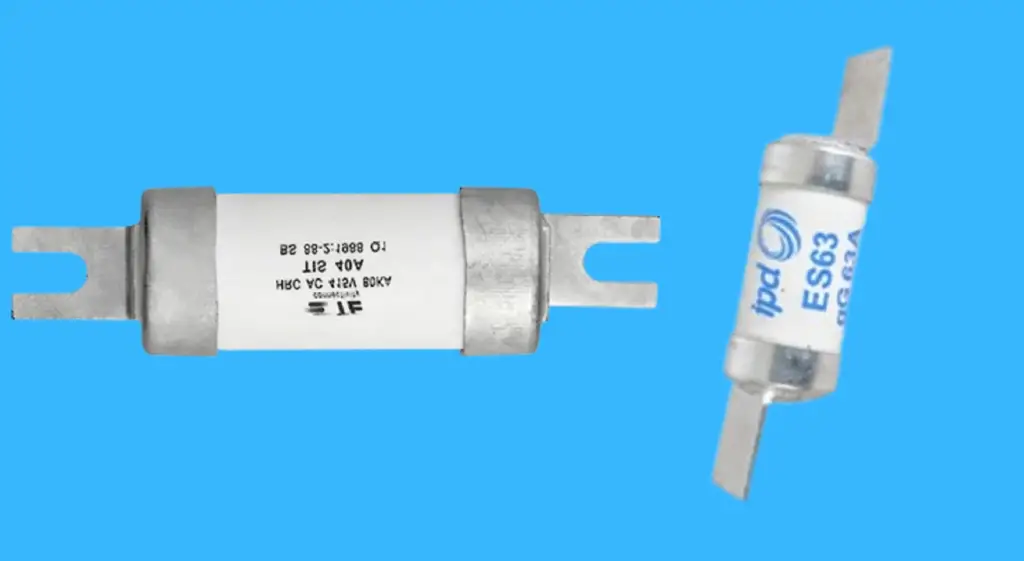

Cartridge Fuse

Cartridge fuses are cylindrical in shape and may be either fast-acting or time-delay. These fuses contain a metal element that melts when an overload occurs, thereby breaking the circuit. This type of fuse is used commonly in household appliances and electrical outlets. They are one of the most common types available and provide an economical option for overcurrent protection.

Blade Fuse

A blade fuse looks like a rectangular block with two prongs on one end that can be inserted into an automotive fuse box. When an excessive current flows through the circuit, it will cause the metal link inside the fuse to melt and break, thus interrupting current flow and protecting any other electrical components from damage.

D-Type Cartridge Fuse

The D-Type cartridge fuse is the most common type of fuse. It is cylindrical in shape and consists of two pieces: a metal cap and a plastic body with terminals. Its design allows for easy replacement, as no special tools are needed to change it out or install it onto the circuit board. The size of the fuse can range from 1/8th inch all the way up to 5 inches and its amperage rating depends on its size. [5]

Link-Type Cartridge Fuse

The Link-Type cartridge fuse is very similar in shape to the D-Type, but has a different construction. Instead of the two pieces (metal cap and plastic body) it contains just a single piece which is made out of ceramic or glass material. It also requires special tools for installation and removal as its terminals are not exposed like that of the D-Type fuse.

Striker Fuse

Striker fuses, also known as plug-in fuses, are usually found in old appliances. Striker fuses consist of two metal contacts connected by a spring or wire inside a plastic casing. If the current passing through the circuit is beyond the rated capacity of the fuse, then the spring will heat up and break contact with one of the metal contacts, thus cutting off power to that device. To restore power, simply remove the old striker fuse and replace it with a new one.

Switch Fuse

A switch fuse is a type of circuit breaker that incorporates a manual on-off switch with the protective characteristics of a fuse. Unlike regular fuses, the switch fuse can be reset after it trips. This allows for easy restoration and maintenance of service, reducing costly call-outs for emergency repairs and allowing for scheduled maintenance intervals to be established. Switch fuses are also known as “fuse switches” or “switch-disconnectors.” They are most commonly used in industrial applications where large amounts of current need to be switched off safely and quickly.

Expulsion Fuse

An expulsion fuse is made up of a metal tube that contains a core element of various materials, such as aluminum or copper wire, which is surrounded by an insulating powder. When the current passing through the fuse exceeds its rating, the core melts and evaporates, expelling the insulating material from both ends of the fuse. This creates an open circuit, interrupting the flow of electricity and protecting against overloads. Expulsion fuses are used in medium voltage applications where they must be able to handle large levels of current while reacting quickly to disturbances.

Drop-out Fuse

Drop-out fuses are usually the smaller type of fuse, often used in residential or light commercial applications. These types of fuses work by melting when the current overloads within a set amount. This causes them to open, or “drop out,” effectively disconnecting the circuit and stopping further damage from occurring. When this occurs, an indicator wire is exposed that shows that the fuse has blown. To replace these types of fuses, they must be replaced with another drop-out style fuse that is rated for the amperage required in the application.

Uses and Applications of Fuses

Fuses are important components of electrical systems, and they have many uses and applications. Fuses can be used to protect circuits from overloads, prevent fires due to short-circuiting, and isolate electrical current from other components in a system. They are also used for safety, as they provide an easy way for users to shut off power in the event of an emergency.

Fuses come in a variety of types suitable for different applications. Slow-blow fuses are designed to handle small overloads without tripping, making them useful for protecting against momentary spikes in current or voltage caused by starting motors or other high-power devices.

Fast-acting fuses respond quickly to surges in current or voltage and disconnect power, making them ideal for protecting against short-circuiting. Time-delay fuses are designed to allow short overloads while still protecting the system from serious damage, making them useful in applications where motors or other large loads start up but require a stable current over time.

Fuses are used in many different electrical systems, including residential and commercial wiring, automotive and industrial equipment, and even aerospace applications. They are also commonly found in appliances such as air conditioners and microwaves, as well as computers and electronic devices. Fuses provide an essential layer of protection for any electrical system by limiting the amount of power allowed through the circuit, preventing costly fires or damage due to overloads. [6]

FAQ

How many types of fuse are there?

There are four main types of fuse: slow-blow, fast-acting, ceramic, and blade. Slow-blow fuses operate best with short duration overloads such as motors or transformers. Fast-acting fuses can handle longer duration overloads such as those caused by an arc fault. Ceramic fuses may be used for high current applications and offer superior protection from overcurrents. Blade fuses provide reliable protection in automotive circuits that experience a large number of start/stop cycles.

What is the most common fuse class?

The most common fuse class is the Class RK5 Fuse. These fuses are designed for branch circuit protection in residential, commercial and industrial applications. A Class RK5 Fuse consists of a metal body with an internal element that melts when an overload or short-circuit current passes through it, interrupting the flow of electricity to protect the circuit from damage. They come in various sizes and amperage ratings to suit different applications. Additionally, these fuses are readily available and relatively inexpensive compared to other types of fuses. Because of these features, they have become one of the most widely used fuse classes on the market today.

What are the 3 main ratings of fuses?

Voltage rating indicates the maximum operating voltage that a fuse can safely handle without breaking down. Interruption rating is the amount of current a fuse can interrupt without damaging itself or other components on the circuit. And finally, ampere rating specifies the maximum amount of current a fuse will allow to pass through it before tripping or opening up. All three of these ratings must be considered when selecting the proper type of fuse for an application.

How do I choose A fuse type?

Choosing the right fuse type for your application can be a difficult task. There are many factors to consider, including current rating, voltage rating, time-delay characteristics, and size.

The most important factor is the device’s current rating. This determines the amount of amperage that is allowed to pass through the fuse. It must be matched with the total current draw of all connected devices in order to prevent damage due to overload or short circuit conditions.

After determining the proper current rating of the fuse needed, you should then consider its voltage rating and time-delay characteristics. Voltage ratings tell you how much voltage the fuse will safely carry without blowing; higher voltage ratings can handle higher voltages without issue. Time delay characteristics refer to how quickly or slowly a fuse will blow if an overload occurs; some fuses are designed to handle short-term overloads, while others are better suited for longer-lasting high-current applications.

Finally, you’ll need to consider the size of the fuse needed—it’s important that it fits into your application correctly. Once you’ve taken all these factors into account, you should be able to narrow down your choices and find the right fuse type for your needs.

Which is the fastest fuse?

There is no single answer to this question as it depends on a variety of factors, including the current rating, voltage rating and time-delay characteristics. However, generally speaking, fast-acting fuses are usually better suited for short-term overloads. Fast-acting fuses react very quickly in order to protect devices from damage due to high currents. On the other hand, slow-blow or time delay fuses are better suited for longer-term overloads that might not be noticed immediately by a fast-acting fuse. These fuses take more time before they trip and can be useful in applications with heavy start up loads.

Useful Video: Fuse Types – Ultimate Guide For Beginners

Conclusion

In conclusion, when choosing a fuse type, it is important to consider the needs of the environment and application. The circuit must be protected from overloads, shorts and faults while allowing normal operation. From fast-acting fuses to time-delay fuses and high voltage fuses, there are different types available that can meet any requirement. Selecting the right type of fuse for an application will ensure safe operation, minimize downtime, and maximize efficiency.

Regardless of which type is chosen, periodic maintenance should always be conducted in order to keep the system running smoothly. This includes visual inspections as well as replacing worn or damaged components with new ones. Ultimately, understanding each fuse’s characteristics and selecting accordingly can help to ensure the safety of a system and its components.

References

- https://uk.rs-online.com/web/content/discovery/ideas-and-advice/fuses-guide

- https://www.electricaltechnology.org/2014/11/fuse-types-of-fuses.html

- https://components101.com/articles/different-types-of-fuses-and-their-applications

- https://electrouniversity.com/fuse-types/

- https://www.elprocus.com/what-is-fuse-different-types-of-fuses-and-applications/

- https://www.wellpcb.com/types-of-fuses.html

Leave a Reply