So you’ve got a galvanized steel project and you’re not sure if you can solder it. Don’t worry, this comprehensive guide will answer all of your questions! In this article, we’ll discuss what galvanized steel is, the pros and cons of soldering it, and how to do it properly. We’ll also provide some tips to make the process easier for you. By the end of this article, you’ll be able to make an informed decision about whether or not soldering galvanized steel is the right choice for your project.

What is Soldering Process

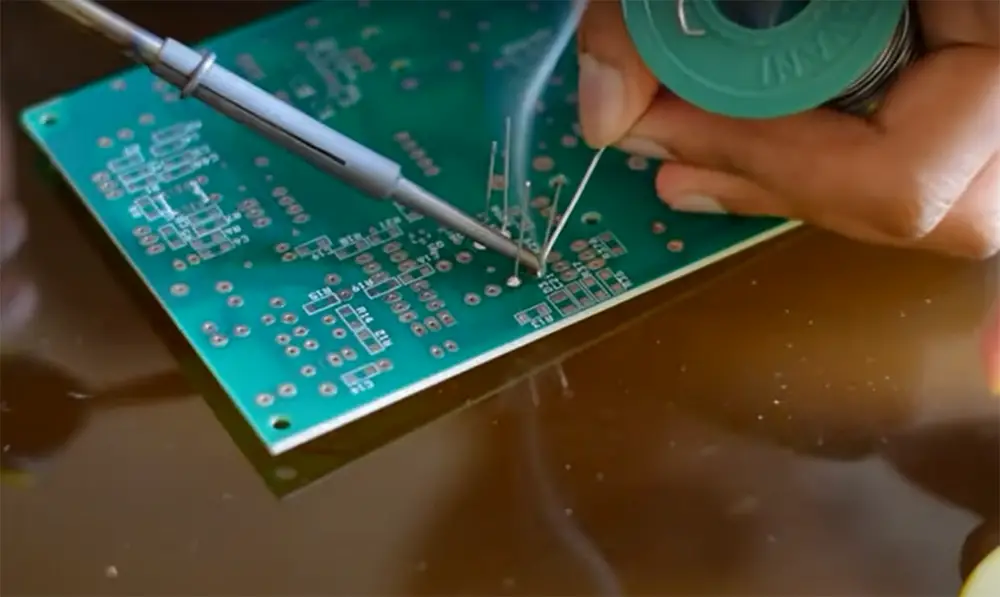

In order to better answer the question “can you solder galvanized steel” it is important to have a general understanding of what soldering is. Soldering generally involves the use of a hot iron to melt a lead-based alloy, which then cools and hardens to create a durable joint between two pieces of metal.

The main advantage of soldering over other methods of joining metals, such as welding, is that it can be done relatively quickly and does not require any special equipment beyond a soldering iron. Additionally, soldering doesn’t damage the metal like welding can, making it ideal for delicate projects.

Why Soldering Galvanized Steel is Seen as Complicated

Galvanized steel is simply regular steel that has been covered in a zinc coating. This process is called galvanization and it protects the steel from rust and corrosion.

You’ll often find galvanized steel in outdoor applications like fencing, roofing, and gutters. It’s also common in automotive parts, appliances, and even some plumbing fixtures because of its durability and resistance to corrosion.

Galvanized steel is known to have poor thermal characteristics. This is because of the said zinc coating that protects it from any harm.

The zinc coating will prevent the heat from the soldering iron from reaching the steel, which means that you won’t be able to create a proper joint. Zinc also has different properties than other metals, so it can be difficult to work with if you’re not used to it.

There are some methods that can be used to solder galvanized steel however, and we’ll go over them in the next section. [1], [2], [3]

How to Properly Solder Galvanized Steel

Sand the surface

The first step is to sand the surface of the galvanized steel. This will help to smoothen it out and remove any potential obstacles that could get in the way of the soldering process. If your metal has inconsistencies, it could cause the joint to be weaker. You can use a variety of sandpaper grits, but we recommend starting with a medium-grit sandpaper and then working your way up to a finer grit. Just make sure to not apply too much pressure, as you don’t want to damage the metal. [2]

Wipe the surface

The second step is to wipe the surface of the galvanized steel with a clean cloth. This will remove any dust or debris that might have been left behind from sanding. It’s important to make sure that the surface is completely clean before you start soldering, as any contaminants could prevent the joint from forming properly. [2]

Drive a pushpin through a steel wool

The third step is to drive a pushpin through a piece of steel wool near the galvanized steel. This will help to create a small area of exposed metal that can be used for soldering. Make sure that the steel wool is clean and free of any debris before you start. [2]

Rub the surface with liquid flux

Heat the soldering gun to the maximum heat setting

Now it’s time to heat up your soldering gun. You’ll want to set it to the maximum heat setting, as this will help to ensure that you’re able to get a proper joint. If the gun is not hot enough, it will be difficult to solder the galvanized steel. [2]

Use a generous amount of solder

Once the soldering gun is heated, you’ll need to use a generous amount of solder. Solder is what actually creates the joint between two pieces of metal. You’ll want to make sure that you’re using enough solder, as this will help to ensure a strong and durable joint.

We recommend using an acid core solder. This type of solder is designed for use with galvanized steel and other metals that are difficult to solder, as this will help to prevent the zinc from corroding the joint. Double check that you’re using the correct type of solder, as this will help to ensure a proper joint. Rosin solders for example, are not going to work well with galvanized steel.

If you’re having trouble getting the solder to stick, try slowly turning the soldering device. This will help to heat up the metal and make it easier to solder. [2], [3]

Start working on the galvanized steel

Now it’s time to start working on galvanized steel. You’ll want to make sure that you’re moving the soldering device slowly and evenly over the surface. If you move too quickly, you run the risk of not heating the metal evenly, which could cause problems with the joint.

You should also be careful not to touch the tip of the soldering device to the galvanized steel for too long. This can cause damage to the coating and make it difficult to solder properly.

Once you’ve finished soldering, you’ll want to allow the joint to cool for a few minutes before moving on. This will help to ensure that the joint is strong and durable. Be sure to inspect the joint closely. If there are any gaps or voids, you’ll need to fill them in with more solder to ensure a strong and durable joint. [2]

Extra tips

Now that you know the basics of soldering galvanized steel, here are a few extra tips to help you get the best results.

Clean sticking metal pieces from your soldering device

If you find that there are metal pieces stuck to the tip, you’ll need to remove them before continuing. The best way to do this is to rub the tip against steel wool. This will help to ensure that the joint is strong and durable. [2]

Re-apply the flux if necessary

As you’re working, you’ll want to keep an eye on the flux. If it starts to turn black or smoke, this is a sign that it’s time to apply more flux. Applying more flux will help to ensure that the joint is properly cleaned and protected from oxidation. [2]

Wipe the soldering area after each pass

You’ll also want to make sure that you’re wiping the soldering area after each pass. This will help to remove any debris or acid that could prevent the joint from adhering properly.

The best tool for this is an abrasive sponge. You can find these at most hardware stores.

You should also be sure to wear gloves when you’re working with galvanized steel. This will help to protect your hands from the corrosive nature of the zinc. [2]

Exploring the Feasibility of Soldering Galvanized Steel: A Comparative Analysis

This table compares the various indicators that determine whether or not galvanized steel can be soldered.

| Indicator | Galvanized Steel | Other Metals |

|---|---|---|

| Melting Point (°F) | 787 | Depends on the metal |

| Solderability | Poor | Good |

| Corrosion Resistance | Good | Depends on the metal |

| Zinc Oxide Fumes | Toxic | N/A |

The table highlights the important indicators for soldering galvanized steel compared to other metals. The melting point of galvanized steel is 787 °F, which is relatively low compared to other metals. However, soldering galvanized steel is challenging due to poor solderability. The zinc coating on galvanized steel provides good corrosion resistance, but when heated during soldering, it produces toxic zinc oxide fumes. Therefore, it is not recommended to solder galvanized steel without proper ventilation and protection. In comparison, other metals may have higher melting points, but they generally have better solderability and do not produce toxic fumes during soldering.

FAQ

How do you join galvanized steel?

Welding, brazing, and mechanical fasteners are the best methods for joining galvanized steel. Of course soldering is also an option, but it isn’t as strong as the other three methods.

Galvanized steel is coated with a layer of zinc to protect it from corrosion. This makes it difficult to weld because the heat of the welding melts the zinc and causes it to vaporize.

How do you solder galvanized steel pipe?

The most common way to solder galvanized steel pipe is with a soldering iron and lead-free solder. You’ll need to clean the pipe with a wire brush to remove any debris or rust. Once the pipe is clean, apply heat to the area you want to solder. Then touch the tip of the soldering iron to the lead-free solder and apply it to the joint.

Is it safe to solder galvanized steel?

The main safety concern when soldering galvanized steel is the zinc fumes. Zinc fumes can be dangerous if inhaled in large quantities, so it’s important to work in a well-ventilated area.

Finally, it’s important to wear gloves and eye protection when soldering galvanized steel. The zinc fumes can be irritating to your skin and eyes, so it’s best to take precautions.

What kind of solder do you use on galvanized steel?

You can use any type of solder on galvanized steel, but acid-core solder is the best choice. This type of solder will create a stronger bond and is less likely to cause corrosion.

What happens if you don’t use the right type of solder when working with galvanized steel?

If you use the wrong type of solder when working with galvanized steel, it can cause the zinc coating to corrode. This will then lead to the formation of zinc oxide, which can be very damaging to the metal.

Therefore, it is important that you use a type of solder that is designed specifically for use with galvanized steel. This will help to prevent any damage to the metal and will also ensure that your work is up to standard.

If you are unsure about which type of solder to use, then you should always consult a professional before starting any work on galvanized steel.

What are the benefits of soldering galvanized steel?

There are many benefits to soldering galvanized steel. For one, it is a very strong and durable material. Additionally, it is resistant to corrosion and rust. Finally, it is also relatively easy to work with compared to other metals.

With all of these benefits, it is no wonder that so many people choose to solder galvanized steel when they need a strong and reliable metal for their projects.

Of course, as with any material, there are also some drawbacks to soldering galvanized steel. One of the biggest is that it can be difficult to find the right type of solder for the job. Additionally, soldering galvanized steel can produce harmful fumes if not done properly.

Overall, though, soldering galvanized steel is a great option for those looking for a strong and reliable metal for their projects. Just be sure to do your research and take all of the necessary precautions before beginning any soldering project.

Are there any dangers associated with soldering galvanized steel?

The fumes from soldering galvanized steel can be harmful, so it’s important to work in a well-ventilated area. Inhaling the fumes can cause metal fume fever, which is similar to the flu and can lead to pneumonia. Symptoms include chills, fever, chest pain, and shortness of breath. If you experience these symptoms after soldering galvanized steel, seek medical attention immediately.

There are also some risks associated with using a soldering iron on galvanized steel. The zinc coating on the steel can be toxic if ingested, so it’s important not to heat the coating to the point where it begins to smoke or vaporize. Additionally, the high temperatures involved in soldering can potentially damage the galvanized coating, which could lead to the steel rusting.

If you’re concerned about the potential risks of soldering galvanized steel, you can take some precautions to minimize them. First, make sure to work in a well-ventilated area to avoid inhaling the fumes. Second, don’t heat the zinc coating to the point where it begins to smoke or vaporize. Third, use a compatible solder to minimize the risk of ingestion. And fourth, be sure to clean up any zinc oxide residue after soldering is complete.

Can you solder galvanized steel to galvanized steel?

The process of soldering two pieces of galvanized steel together is generally the same as soldering any other type of metal. The main difference is that you need to be aware of the zinc coating on galvanized steel, which can be poisonous if inhaled. To get the best results, we suggest you use zinc chloride based flux, and a high quality solder.

Will JB Weld work on galvanized pipe?

It is possible to use JB Weld on galvanized pipes, but it is not recommended. JB Weld is designed to adhere to metal surfaces, and the zinc coating on galvanized pipes can prevent the epoxy from bonding properly. In addition, JB Weld can be difficult to remove from galvanized surfaces if you ever need to make repairs in the future.

Can galvanized steel be welded?

Galvanized steel can be welded, but it will become very brittle and will easily break apart. Welding galvanized steel is also not recommended because the zinc coating will create a poisonous gas that can be harmful to your health.

If you must weld a galvanized pipe, make sure to wear a respirator and gloves to protect yourself from the fumes.

What is the best way to weld galvanized steel?

Unfortunately, to properly weld galvanized steel you will need to remove the zinc coating. This can be done with a wire brush, sandpaper, or a chemical stripper. Once the zinc is gone you will be able to weld the steel as normal.

Welding galvanized steel without removing the zinc coating is possible, but not recommended. The zinc will melt and vaporize during welding, which can lead to health problems for the welder. Additionally, the weld will not be as strong as it could be if the zinc was removed first.

Can you weld galvanized with flux core?

Yes, you can weld galvanized steel with flux core welding. The main difference between welding galvanized steel with flux core and other methods is that the zinc coating on the steel will burn off during the welding process. This means that you need to be extra careful not to overheat the steel or damage the coatings.

Another thing to keep in mind when welding galvanized steel with flux core are fumes. The fumes from welding galvanized steel can be dangerous if inhaled. Be sure to weld in a well-ventilated area and use a respirator or other personal protective equipment to protect yourself from the fumes.

Finally, you need to be aware of the fact that welding galvanized steel will create a lot of sparks. Be sure to wear proper eye protection and take precautions to avoid starting fires.

Useful Video: how to solder galvanized steel

Final thoughts

Soldering galvanized steel can be tricky, but with a little practice, you should be able to get the hang of it. Just remember to take your time and be careful not to overheat the metal. If you do, you run the risk of damaging the galvanized coating and making it difficult to solder properly. Always sand the area prior to soldering to ensure a good connection. Now that you know the basics of soldering galvanized steel, get out there and give it a try! With a little practice, you should be able to master this challenging technique. Thanks for reading! We hope this guide was helpful!

References:

- https://www.muggyweld.com/video/solder-galvanized-steel/

- https://www.hunker.com/13402935/how-to-solder-galvanized-steel

- https://www.ehow.co.uk/how_6942534_do-distinguish-between-benzene-cyclohexane_.html

Leave a Reply