Have you ever been curious about the intricate workings of your household electric equipment? Or what goes on behind the scenes of an industrial facility to keep its operations going? Well, one crucial component that plays a role in these scenarios is known as a fusible resistor. Fusible resistors are essential for safely regulating and controlling the electrical current within any given appliance or structure. In this blog post, we’ll explore some basics about fusible resistors and why their performance is so important!

What is a Fusible Resistor?

It basically acts like a fuse, but does not require manual replacement after it trips. Fusible resistors are designed to activate when exposed to abnormal current levels, providing short-circuit protection for sensitive electronic components. They can be used in many applications such as overcurrent protection for power supplies, motor control circuits, adjustable regulators and inverters. Fusible resistors are available in various sizes and resistance values, so they can be tailored to meet specific needs. [1]

How Do Fusible Resistors Work?

Fusible resistors are designed to protect circuits from over-voltage conditions. They work by acting as a fuse, which will open when the voltage exceeds its rated value. This prevents further damage from occurring in the circuit due to excessive current flow. When the resistor opens, it interrupts power to the circuit and stops any further current from flowing. This ensures that no further damage is done to components in the circuit and helps prevent fires caused by overloaded circuits.

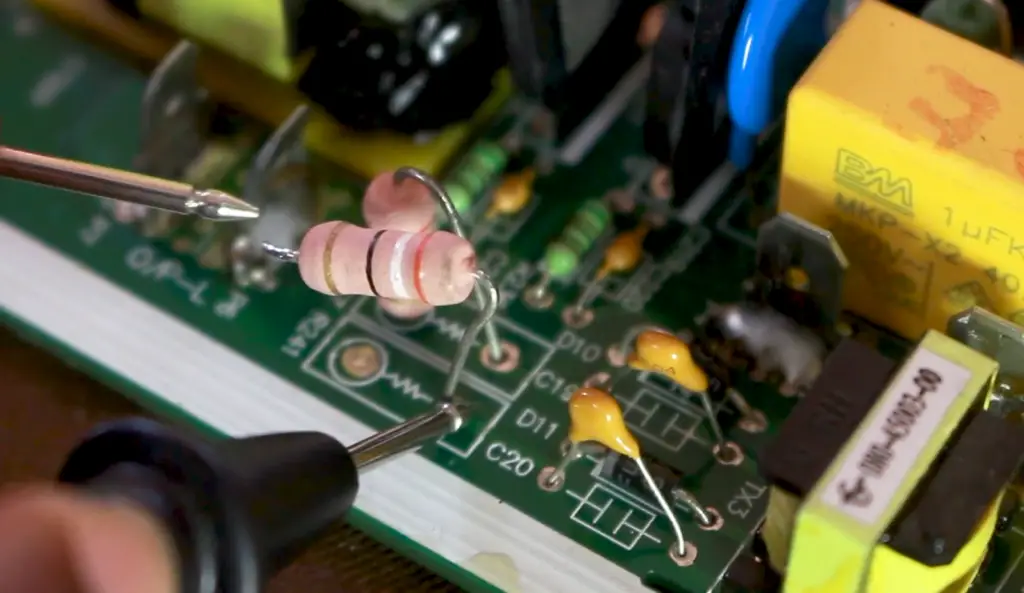

In order for a fusible resistor to work correctly, it must be sized properly for the application it is being used in. Typically, these resistors will have lower wattage ratings than other types of resistors because they are only meant to handle currents up to their rated value. This ensures that they will open before the circuit is damaged by too much current flow. Once a fusible resistor has opened, it must be replaced with one of the same rating and size in order to keep the circuit safe.

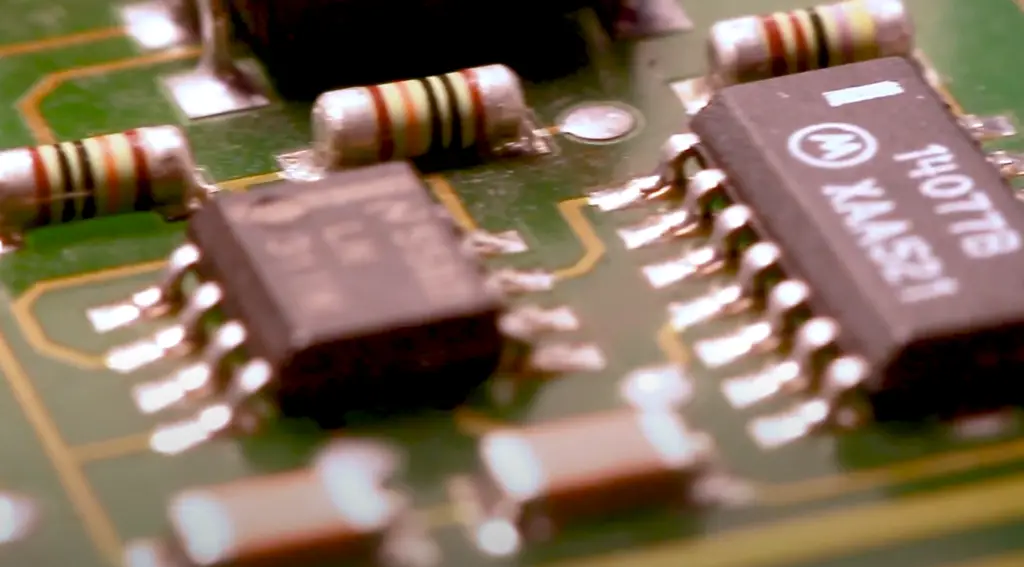

Fusible resistors are commonly used in automotive, appliance, computer, and other applications where voltage control is important. They can provide an effective way to protect circuits from electrical damage while also providing ease-of-use for installers and maintenance personnel. By having a fusible resistor installed in a circuit, users can be sure that any overvoltage conditions will be quickly detected and prevented before further damage is done to components or wiring.

Advantages of Fusible Resistors

Fusible resistors have a number of advantages, including:

- Lower cost and higher reliability. Fusible resistors are usually cheaper and more reliable than their non-fusible counterparts, making them an attractive option for high-volume applications.

- Reduced power dissipation. Fusible resistors dissipate less power than regular resistors, which can help reduce heat buildup in a circuit and make it easier to achieve thermal management goals.

- Protection against overloads. Fusible resistors are designed to fail safely when they’re exposed to excessive current or voltage loads, protecting sensitive components from damage caused by overloading or short circuits.

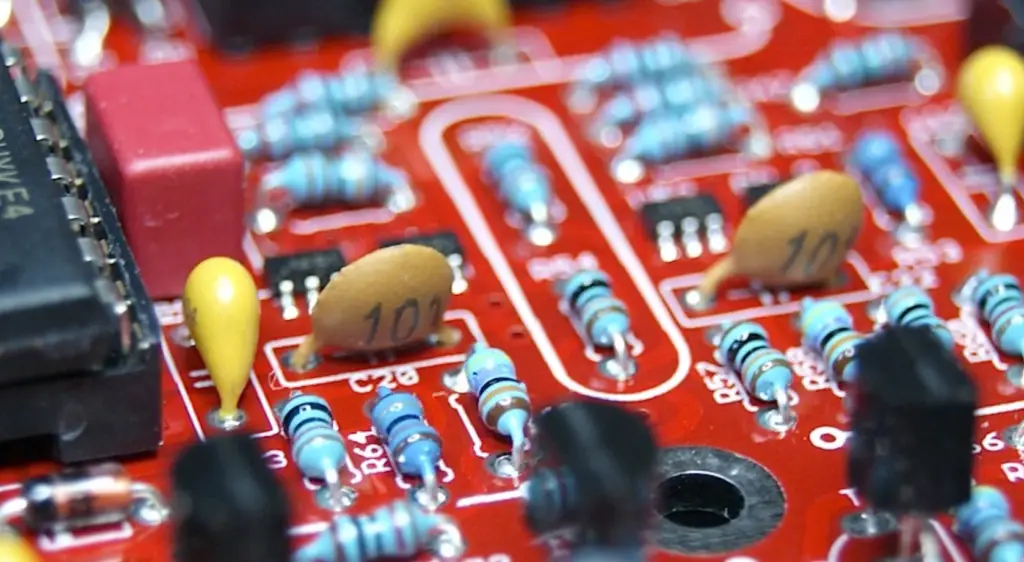

- Ease of installation. Fusible resistors are usually smaller than other types of resistors, making them easier to install in cramped spaces and on crowded circuit boards.

- Simple replacement. In the event of a failure, fusible resistors can easily be replaced without special tools or skills. This makes it easy to reset a circuit after an overload or short-circuiting has occurred.

Overall, fusible resistors offer many advantages for circuits that need reliable protection against overloads or high power dissipation levels. They are cost effective and simple to use, making them an attractive option for many applications. [2]

Disadvantages of Fusible Resistors

- Fusible resistors can only be used once; they must be replaced after they have blown.

- They are not as accurate as other types of resistors, so they are not suitable for use in precision circuits.

- Because they rely on a physical property (melting) to function, fusible resistors are slow to react compared to other types of overcurrent protection devices. This can lead to damage to the circuit before the fuse blows.

- They are relatively expensive compared to other types of resistors.

- Fusible resistors can also be affected by environmental variables such as temperature and humidity, which could cause them to blow unexpectedly.

- They are not suitable for use in high power applications due to their limited ability to handle large currents. This means that they are typically used only in low-power circuits.

Overall, fusible resistors are a reliable way to protect circuits from damage caused by an overcurrent, but they have certain limitations and drawbacks which should be taken into consideration when selecting them for use in a circuit. By understanding the advantages and disadvantages of using fusible resistors, you can make the best choice for your application. [3]

Fusible Resistor Symbol

The fusible resistor or fuse symbol is a circle with 2 vertical lines running through it. It is usually used to denote a component that will protect the circuit from damage due to overcurrent conditions. A fusible resistor has two terminals and when an excessive current passes through it, the component ‘burns’ open causing the current to be limited in order to prevent further damage. Fuses are commonly used in circuits involving large currents and high voltages but can be found in other applications as well.

Fuses come in different sizes depending on their current rating and voltage rating, so they must be chosen carefully according to the application they are being used for. In addition, some resistors also have thermal protection features that limit the amount of heat they can take before they trip. This helps to protect components and other devices from overheating.

When installing a fusible resistor, it is important to make sure that the current rating matches with the expected load and that any safety features are enabled. It should also be placed in an easily accessible location for easy replacement if necessary. Finally, all wiring must be done according to the manufacturer’s specifications in order to ensure optimal performance.

Fusible resistors are useful components for protecting circuits from damage due to overcurrent conditions and can help extend their lifespan by preventing catastrophic failure from occurring. They must be chosen carefully and installed correctly in order to provide adequate protection for your circuit or device.

Fusible Resistor vs. Fuse

Fusible resistors and fuses are both devices used to protect electrical circuits and components from overloads. Fuse is the traditional choice for most circuit protection applications, while a Fusible Resistor is more often utilized as a supplemental or alternative protection device.

The primary difference between fusible resistors and fuses is that fuses act as an open switch when they trip, interrupting power flow while a Fusible Resistor still provides some resistance to current passing through it even after it has tripped. This allows for a much lower voltage drop across the resistor than with a fuse and can help reduce stress on the electrical system in certain applications.

In addition, unlike conventional fuses, Fusible Resistors can be reset after the fault has been cleared, allowing for greater reliability when dealing with frequent overcurrents. However, one downside of Fusible Resistors is that they can be slow to trip compared to fuses and may not provide adequate protection against rapid surges or spikes in current.

For most applications, a combination of fuses and Fusible Resistors will provide the greatest level of circuit protection while still maintaining an acceptable level of performance. It’s important to assess each application carefully and utilize both components where appropriate. [4]

Fusible Resistor Calculation

The resistance of the device will depend on its design, but generally speaking, the higher the resistance value, the greater the overload that can be tolerated.

When calculating how much power a fusible resistor can handle, it is important to take into account not only its resistance value but also its rated voltage and maximum surge ratings. For example, if a device has a 10 ohm resistance at 250 volts with a 200-amp surge rating then it would be capable of handling up to 20 kilowatts (kW) of energy. To ensure that the device can safely handle a given load, it is important to make sure its surge rating is at least 5 times greater than the amount of power it must manage.

When selecting a fusible resistor for use in an application, it is important to ensure that its maximum power dissipation rating is high enough so as not to exceed any safety limits. In addition, these devices should be tested regularly and replaced when necessary in order to ensure their safe operation.

Fusible resistors are an important component of many electrical systems and can be used both to protect components from damage due to excessive current or voltage and also to limit the amount of energy being supplied by a circuit.

Fusible Resistor Applications

Fusible resistors are used in a variety of applications in electronics. They can be used to protect circuits from large surges or spikes, such as those caused by power outages, or from short circuits due to damaged wiring or circuit boards. They may also be employed to provide an easy way to repair open circuits without having to completely dismantle the device.

Types of Resistors

Resistors are divided into two distinct categories based on their individual characteristics: fusible resistors and non-fusible resistors.

Fusible resistors contain a special resistance element that is designed to melt under certain conditions of overload or short circuit, breaking the electrical current flow in the process. This “fusing” capacity of these components makes them ideal for use in hazardous environments where sparks from electrical shorts could be dangerous.

Non-fusible resistors, on the other hand, do not contain any elements that can fuse under extreme conditions; instead they are designed with higher wattage ratings which enable them to handle high levels of current without failing. The most common type of non-fusible resistor is the carbon film resistor, which is a thin film of carbon sandwiched between two metal plates. This type of component is widely used in electrical circuits due to its low cost and reliability.

In order to ensure optimal performance, it is important to choose the correct type of resistor for any given application. Different resistors are designed with different wattage ratings, so if an application requires a higher wattage than the standard rating, then using a non-fusible component may be the best option for safety and durability. On the other hand, if an application has relatively low current flow requirements, then using a fusible resistor would be more appropriate as it can provide adequate protection from short circuits without sacrificing too much in terms of resistance value. [5]

Where to Buy Fusible Resistors?

Fusible resistors are readily available and can be purchased at many hardware or electronic stores. Online, they are also widely available with a variety of sizes, shapes, and characteristics. It is important to select the appropriate resistor for your application; so, before purchasing, make sure you understand all of your technical requirements. Ensure that you purchase from a reputable supplier as low-quality components may not withstand the current flow over time.

Additionally, double check the specifications on the manufacturer’s data sheet prior to purchasing. With proper selection and installation, fusible resistors will provide reliable services in applications requiring overload protection for years to come.

Fusible Resistors Challenges

Fusible resistors have some significant challenges. They are limited in their current carrying capacity and cannot be used for high power applications. Moreover, the low voltage rating of most fusible resistors does not permit them to be used for high voltage applications. In addition, the small physical size limits their working frequency range.

Finally, the cost of fusible resistors can make them prohibitively expensive for many applications. For these reasons, they are often replaced by other components or devices when a circuit must handle higher power levels or operate at a wider range of frequencies than what can be achieved with a fusible resistor.

Overall, while fusible resistors may offer advantages over other electronic components in certain applications, it is important to be aware of the limitations and possible alternatives. When selecting a fusible resistor for a particular application, it is wise to consider all available options and weigh their benefits and drawbacks carefully.

For applications requiring high power, wide frequency range or high voltage levels, other components such as MOVs or TVS diodes may provide superior performance and durability. For these situations, it makes sense to explore all available choices before making a final decision. Doing so can help ensure that the best choice has been made for the particular application in question. [6]

FAQ

How do you know if a resistor is fusible?

If your resistor is labeled as fusible, it has a much higher resistance value than normal resistors. This allows it to act as an overcurrent protection device and will break the circuit if too much current passes through it. The higher resistance also makes them uncomfortable to touch due to their heat generation. Additionally, a visual indicator may be present on the resistor which can signify that the resistor is indeed fusible.

What kind of applications use fusible resistors?

Fusible resistors are used in various circuits and applications where overload protection is required or desired. Some examples include automotive electronics, home appliances, power tools, LED lighting systems, and even industrial machinery. They are most commonly used in circuits containing high-power transistors and other components that require surge protection. Fusible resistors are also used in audio systems as they provide greater protection from power surges or shorts compared to traditional resistors.

What should you consider when selecting a fusible resistor?

When selecting a fusible resistor, it is important to consider the type of load you will be using, the maximum current and voltage of your circuit, and any environmental conditions your application may be exposed to. Additionally, some types of fusible resistors have various features such as temperature-dependent resistance for controlling operating temperature or thermal protection for added safety. It is important to ensure that the product you select fits all of your requirements before making a purchase.

What problems can appear?

Fusible resistors can fail for a variety of reasons. Excessive heat is the most common cause, but other factors such as mechanical shock, vibration or humidity can also contribute to a failure. If too much current passes through the resistor, it will overheat and potentially catch fire. Similarly, if the resistor is placed too close to an electrically conductive material, a short circuit may occur. The result of any of these scenarios could be catastrophic damage to both the device and its wiring.

Can I replace a fusible resistor with a normal resistor?

No, you cannot replace a fusible resistor with a normal resistor. A fusible resistor has characteristics that allow it to safely burn out or disconnect an electrical circuit when overloaded. This provides protection from dangerous currents and helps prevent fires in electronic devices. Normal resistors do not have this capability and so should not be used as a substitute for a fusible resistor. It is important to use the correct type of component in any given circuit to ensure safety and reliability.

Are resistors used as fuses?

Yes, resistors can be used as fuses. This type of component is referred to as a fusible resistor. Fusible resistors are composed of wire wound around a non-conductive core and encased in an insulating material like epoxy or ceramic. When the current passing through the resistor exceeds its rated value, it causes heat to build up internally which eventually melts the insulation on the metal core and breaks the circuit. This prevents further current from flowing and protects components connected downstream from being damaged by overloads. Fusible resistors have many uses including circuit protection, power limiting, inrush current suppression, overvoltage protection and more. All these applications make them valuable components for various electrical circuits and systems.

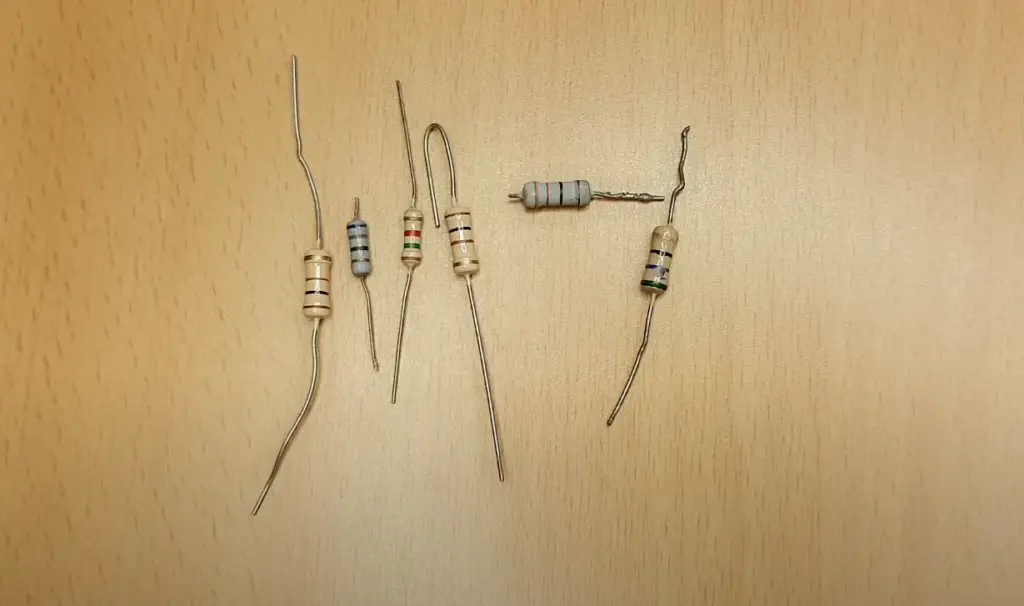

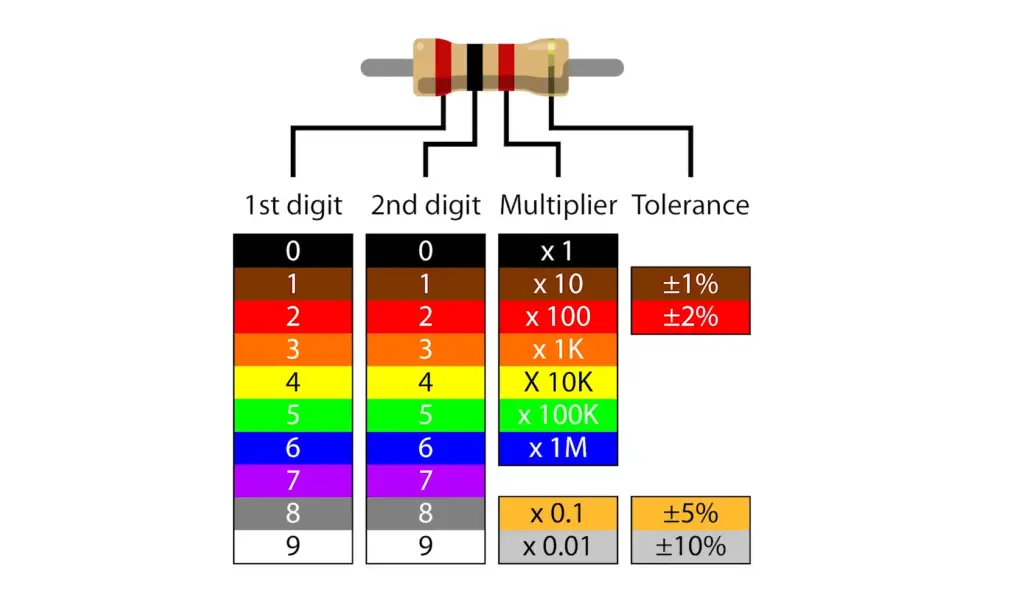

What is the color code of a fusible resistor?

The color code of a fusible resistor usually consists of 4 or 5 bands. On the first band, there is typically an indication as to whether it is a fusible resistor or not, such as “F” for fuse. The second and third bands indicate the resistance value in ohms; the fourth band indicates tolerance (±5%, ±10%, etc.). Finally, the fifth band has either a black or red stripe to indicate power rating. For example, a common color code used on most fusible resistors is F68K-1/2W which indicates that it is a fusible resistor with 68K ohms of resistance and 1/2 watt of power rating. In addition to these standard 5-band codes, fusible resistors may also have more specialized color codes used for specific applications.

What are the four types of resistors?

The four types of resistors are carbon composition, wirewound, metal film and fusible. Carbon composition resistors are made from a mixture of powdered coal and graphite. Wirewound resistors have an insulated wire wound around a ceramic core. Metal film resistors use a thin layer of metal deposited on an insulating base material to create their resistance. Fusible resistors are designed with a low-value resettable fuse inside the resistor that will open when the current exceeds its rating. This helps protect circuit components from damage due to overcurrent or short circuits.

Useful Video: Fuse resistance | Fuse resistor value

Conclusion

Fusible resistors are an important safety feature in electrical equipment, protecting against dangerous current overloads that could cause fires or other damage. They are advantageous because they are often cheaper than other types of circuit protection devices, and they can react quickly to short circuits with no additional power source required. Care must be taken when selecting the right fusible resistor for a particular application, as too little resistance can allow high currents that can cause damage. The value of the resistor must also be tailored for the maximum normal operating currents of the system in order to ensure proper operation without risk of nuisance tripping. Overall, fusible resistors provide an easy to use solution for providing circuit protection from overcurrent situations.

References

- https://www.elprocus.com/fusible-resistor/

- https://circuitspedia.com/what-is-fusible-resistor-or-fuse-resistor/

- https://www.icrfq.net/fusible-resistor/

- https://passive-components.eu/fusible-resistors-vs-fuses-key-differences-explained/

- https://www.aillen.com/news-events/what-is-a-fusible-resistor.html

- https://www.powerelectronictips.com/fusible-resistors-vs-fuses-faq/

Leave a Reply