Have you ever wondered what a CBB61 capacitor is and how it differs from other capacitors? If so, you’ve come to the right place! In this comprehensive guide, we’ll explain exactly what a CBB61 capacitor is, why it’s used, and all the useful tips you need to know about it. Take some time to read through this article and you’ll be an expert on CBB61 capacitors in no time!

Capacitors in General

The basic structure of a capacitor consists of two conductive plates, separated by an insulator called a dielectric material. When a voltage is applied across the two plates, electrons accumulate on one plate while leaving holes on the other plate resulting in unequal charges between them. This creates an electric field which stores energy, forming what is known as a capacitance. The amount of stored energy depends on various factors such as the distance between the plates and the type and thickness of the dielectric material.

Capacitors are used to reduce power dissipation in circuits, store energy for later use, filter out noise and regulate voltage levels. They are also used to create an oscillator circuit which is then used in radio communications, antennas and radar systems as well as other applications where a signal at a fixed frequency is required.

The most common types of capacitors include electrolytic, ceramic and film capacitors. Electrolytic capacitors are polarized components that can store the largest amount of charge compared with the other two types but have relatively high leakage current and low tolerance for temperature fluctuations. Ceramic capacitors have excellent stability over temperature and losses due to dielectric absorption, making them suitable for high frequency applications. Film capacitors are known for their excellent temperature stability, high accuracy and low noise. [1]

What Does a CBB61 Capacitor Do

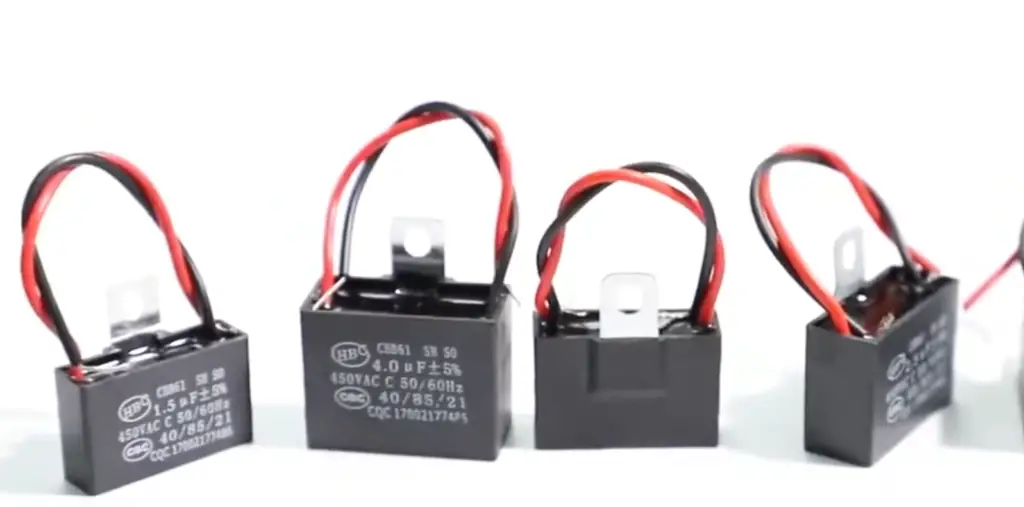

The CBB61 capacitors are constructed with aluminum foils separated by insulating dielectric material composed of paper or plastic film interleaved with metalized layers. This type of construction ensures that it can handle higher voltage levels compared to standard electrolytic capacitors while also offering superior thermal performance due to its better ability to dissipate heat.

A CBB61 capacitor works by passing alternating current (AC) through the capacitor, which produces an electric field across its plates. This electric field stores energy in the form of a charge, which is then released back into the circuit as needed. The amount of stored energy depends on various factors such as the capacitance and voltage rating of the capacitor.

CBB61 capacitors are used to reduce power dissipation in AC motors by smoothing out fluctuations in current flow and providing filtering capabilities for noise and harmonics generated by the motor. They also help regulate voltage levels by storing excess energy when it isn’t needed and releasing it when additional current is required. Additionally, CBB61 capacitors can be used to create an oscillator circuit which is then used in radio communications, antennas and radar systems as well as other applications where a signal at a fixed frequency is required. [2]

What Causes Capacitors to Fail

Now that you know what a CBB61 capacitor is and does, let’s discuss why capacitors fail. Nothing lasts for eternity and eventually, capacitors will fail despite the best efforts of their manufacturers. This can be due to a number of reasons, and we will discuss which ones are the main causes ofitors failure.

Excessive voltage

Excessive voltage is the most common cause of capacitor failure and can happen when the applied voltage is above the rated voltage. Overvoltage stresses and weakens the dielectric material, resulting in leakage current, decreased capacitance and eventual breakdown of the capacitor.

Therefore it’s important to ensure the voltage is within the specified range of the capacitor’s rating. If the voltage is too high, a higher rated capacitor should be used or a series resistor can be inserted in the circuit to limit the current and protect against overvoltage.

Using a capacitor for tasks that require higher voltage range

Another common cause of capacitor failure is using a capacitor for tasks that require higher voltage range than its designed rating. This happens when someone uses a lower rated capacitor to perform jobs which require higher voltage than the rating of the component. The dielectric material breaks down quickly and can damage the circuit components due to excessive current or heat generated by the failed part.

When selecting capacitors, it’s important to make sure they are capable of handling the expected voltage levels and application requirements without fail. Using capacitors with too low ratings can lead to premature failures and decreased life expectancy of other parts in the circuit.

Improper storage

Improper storage of capacitors can also cause them to fail. If the capacitor is exposed to temperatures above its rated temperature, it will deteriorate quickly due to breakdown of the dielectric material. Similarly, storing a capacitor in extreme humidity or wet conditions can accelerate corrosion and reduce the life expectancy of the component.

Therefore it’s important to store capacitors in cool dry places and keep them away from direct sunlight or other sources of excessive heat for longer shelf-lives.

Overload

Overload is another common cause of capacitor failure. An overloaded circuit with too much current flowing through it can damage the dielectric material and cause failure.

These are the main causes of capacitor failure which should be taken into consideration when selecting components for your circuits. By using components with suitable ratings and taking care of storing them in optimal conditions, you can ensure reliable performance of your circuitry and extend its life expectancy. [2]

How Can I Tell if My Fan Capacitor Is Faulty

As you can see, while fan capacitors are built to be durable and last a long time, there are certain circumstances that may cause them to become faulty. And if that happens, it can potentially cause your fan to stop working or even damage other components in your system. To avoid any problems, it’s important you check the condition of your fan capacitor periodically and address any issues before they become a problem.

Case melted or damaged

A fan capacitor is encased in a black plastic shell, and if that casing is melted or damaged in any way, it’s a sign that your fan capacitor may be faulty. This could be due to excessive heat caused by poor ventilation or an overworked motor. In either case, you should replace the capacitor as soon as possible before the problem gets worse.

Smell of burning

Another symptom of a faulty fan capacitor is the smell of burning coming from the device. If you notice this smell, it means there’s likely a short circuit or some other issue causing your capacitor to malfunction. You should shut off power to your fan immediately and then contact a qualified electrician for help with replacing your fan capacitor.

Fan may not start

If your fan capacitor has gone bad, it won’t be able to store the necessary amount of energy needed to start the fan motor. This can manifest itself in various ways, such as the fan not starting at all or even running very slowly and with difficulty. If you experience this issue, it’s likely a sign that your capacitor needs replacing. [3]

FAQ

What is the lifespan of a fan capacitor?

The lifespan of a fan capacitor depends on the quality of the product and how it has been maintained. Generally, fan capacitors have an average lifespan of up to 20 years when used in normal conditions. If your fan is being used for extended periods or in harsh environments, the life expectancy of your capacitor can be reduced significantly. To increase the longevity of your CBB61 capacitor, it’s important to follow all instructions and maintenance procedures given by the manufacturer. To clean and maintain your capacitor properly, you should regularly check for any signs of damage or corrosion and take preventative measures such as using protective covers to protect from dust, moisture and other environmental factors. Additionally, inspect wiring regularly for signs of wear or damage, as this can lead to short circuits and overheating which can cause your capacitor to fail prematurely. By following these instructions and taking a proactive approach, you can extend the lifespan of your fan capacitor considerably.

What is the use of a capacitor in an exhaust fan?

The capacitor works by providing a boost of electrical energy when the fan starts up, which is then used to overcome inertia and get the rotor spinning. It also helps keep the current steady during operation, preventing the motor from stalling or running too slowly due to voltage fluctuation. When looking for capacitors for exhaust fans, look for CBB61 capacitors as they are specifically designed for this purpose.

CBB61 capacitors have AC (alternating current) start and run capacitors, which help to start and maintain the fan motor running. They have a high dielectric strength, making them resistant to breakdown and capable of handling large electrical currents without fail. They also come in various sizes, so you can choose the one that best meets your needs. Furthermore, they are cost-effective and easy to install as well.

To ensure proper operation of your exhaust fan motor with a CBB61 capacitor, it is important to check if the voltage ratings match up with your requirements (for example 220V/50Hz). It is also important to check if there is any damage or corrosion on the terminals before installation. Once installed correctly, it should provide reliable performance for many years to come.

What happens if the fan capacitor fails?

If the fan capacitor fails, it is likely that the fan will not be able to start and operate properly. This would usually result in a noisy operation or no operation at all. In some cases, a failed capacitor can cause electrical arcing which could lead to fire hazards. Therefore, it is important to replace any failed fan capacitors as soon as possible.

When replacing a failed capacitor it is important to choose one with matching specifications (rated voltage, capacitance) of the original part. It is also important to ensure that the terminals are securely fastened for safety reasons. After installation check if the motor turns freely and make sure that there’s no sparking from components when powered up.

In addition, note that most fan capacitors are designed for intermittent use. That means that it can be used for a short period of time but not continuously. Therefore, it is important to understand the usage purpose of your appliance before selecting a replacement capacitor.

Is a CBB60 a start capacitor?

It has a cylindrical aluminum body with two terminations and contains electrolytic capacitors, which are made up of rolled aluminum foil, impregnated paper separators, and a liquid electrolyte. The capacitor is designed to provide starting torque during the motor’s initial period of acceleration, as well as sustaining its operating voltage during normal running operation. The CBB60 also helps to eliminate electrical interference from the motor by providing an electro-magnetic field balance around the AC winding circuits.

Useful Video: New CEILING FAN CAPACITOR CBB61 4.5uf + 6uf + 5uf 5 WIRE 250V

Conclusion

A CBB61 capacitor is an affordable and highly efficient way to improve the performance of motors, fans, appliances and other devices. It helps to maintain the steady flow of power by suppressing the power fluctuations in the circuit. This type of capacitor offers good reliability, long-life span and low ESR values which make it an ideal choice for a wide range of applications.

In this article we have discussed in detail what CBB61 capacitors are and how they work. We have also discussed their important features, applications and installation tips. It is highly recommended that you consult with a qualified professional before installing a CBB61 capacitor as incorrect installations can lead to serious safety hazards.

If you’re still unsure about what CBB61 capacitors are or how they work, there are plenty of resources available online to help you out. Additionally, consult with your trusted service provider if you need more assistance on selecting the right capacitor for your specific application.

The CBB61 capacitor is a cost-effective and reliable solution to many of your common electrical issues. Utilize its features in the best way possible to get the most out of it!

Finally, always make sure to read through all relevant safety instructions before handling any electronic components or working with any type of electrical equipment. This will ensure that you have a safe and enjoyable experience using this versatile device. Thank you for taking the time to read our guide – we hope you found it informative and helpful!

References

- https://electronics.howstuffworks.com/capacitor.htm

- https://www.circuitsgallery.com/what-is-cbb61-capacitor/

- https://www.thedonutwhole.com/what-causes-a-capacitor-to-fail/

Leave a Reply