Whether you’re establishing a new electrical system or simply need to upgrade one that is outdated, an electrical isolator is a must-have component for proper functioning. An essential tool in the field of electricity, it helps ensure the safety and efficiency of any power supply or wiring system by allowing two parts to remain separate while still connected. Electrical Isolators can be used as circuit breakers, voltage regulators, and more – but what exactly are they? Read on to find out all you need to know about this vital component!

What Is An Electrical Isolator?

This can be done by using one or more layers of insulation material, such as ceramic, stone, plastic, rubber, glass and metal. Electrical isolators are commonly used in industrial settings for power distribution systems as well as in automotive applications. They serve the purpose of preventing electricity from flowing through unintended paths and providing necessary protection against electric shock.

Additionally, these devices also help protect sensitive electronic components from static build-up or short circuits. Electrical isolators can often be seen in generator sets and other similar power systems where they are used to separate different sections of the system.

By doing so it allows each section to operate independently and ensures that any potential fault in one section of the system does not affect the operation of other sections. Electrical isolators can come in different forms such as switches, relays, circuit breakers, and even transformers. They are a vital component for providing safe electrical power in industrial settings and can help protect both equipment and personnel from harm due to electric shock or short circuits. [1]

Types Of Electrical Isolators

There are many different types of electrical isolators available depending on the application and size of the system. Common types of electrical isolators include: high voltage disconnect switches, low voltage circuit breakers, ground fault interrupters, fused switch disconnectors, motor contactors and dynamic circuit breakers.

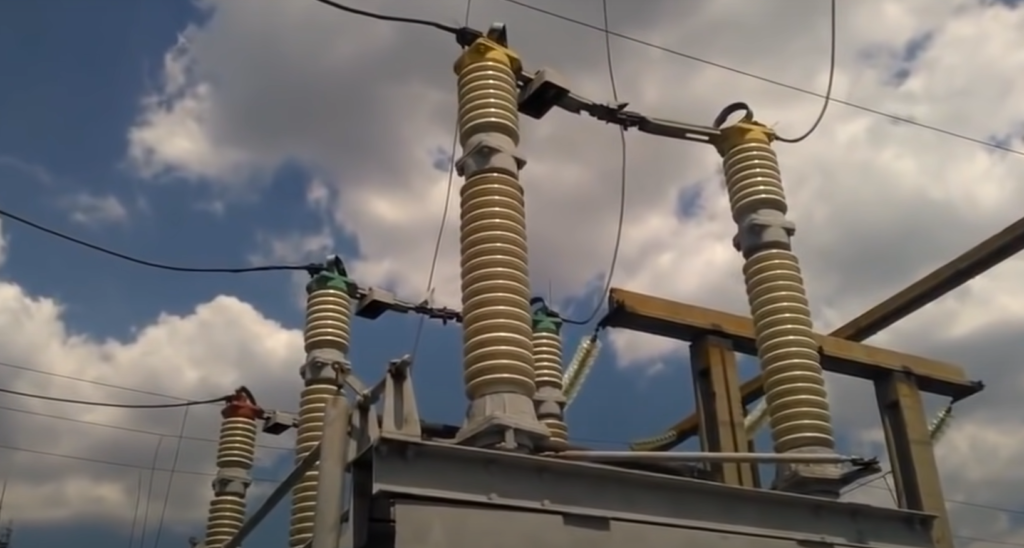

High voltage (HV) isolators can be used to safely isolate electricity supplies up to 600kV while low voltage (LV) isolators can be used for systems below 1000V AC or DC.

Fused switch disconnectors are primarily used in distribution networks where high currents need to be controlled.

Motors contractors provide a safe way to control motors by using an electromagnet with power contacts that open and close as needed.

Dynamic circuit breakers are designed to respond to sudden changes in current by tripping and removing power from the system. These types of isolators are most commonly used in higher voltage systems.

Ground fault interrupters (GFI) are also a type of isolator that will trip if it detects an abnormal current such as a ground fault or short circuit. GFIs are most often used in residential and commercial applications where safety is paramount.

Overall, electrical isolators provide a safe way to isolate electricity supplies so they can be maintained or serviced without any risk of shock or injury to personnel. They come in all shapes and sizes, depending on the application, with some suited for industrial-level applications while others may be more appropriate for residential or commercial use.

No matter the application, having an electrical isolator in place is essential for maintaining safety and protecting personnel from shock related injuries. Ensuring that the right type of isolator is used for each system is key to making sure it functions correctly and reliably. [2]

Working Principle

This allows for safe and effective operations during maintenance or repairs. The working principle of an isolator is simple: when in its open position, no current can flow through it; and when in its closed position, current flows freely between two circuits.

The basic construction of an electrical isolator consists of an insulating material such as rubber or plastic that separates two conducting elements. When the switch moves into the open position, the contact breaker creates a physical separation between these conductors which blocks any electric charge from passing through. The other component is an actuator which operates the switch by turning it on or off, depending on the desired outcome.

Generally speaking, electrical isolators are used to isolate a circuit from ground, as well as providing isolation between two circuits. This can be done by either using mechanical or electronic switches and can be operated manually or automatically depending upon the application’s requirements. Additionally, isolators may also be used in high-voltage applications where they provide protection against electric shock by breaking up the current flow and stopping it from reaching dangerous levels.

Operation Of Electrical Isolator

When an isolator is open, or not energized, it provides complete separation between two parts of a circuit and no current can pass through it. However, when the isolator is closed, or energized, current will flow freely between both sides of the circuit. Electrical isolators help to protect people from contact with hazardous voltages and increase safety in systems with multiple components.

They are commonly used on high voltage circuits such as transformers and substations, but also work on low-voltage circuits too. Isolators typically consist of two insulated contacts that can be opened or closed by an external device such as a switch. When the contacts are opened, power is completely cut off from the circuit with no current flow possible. When the contacts are closed, current can pass freely between the two points of contact.

Electrical isolators are essential to ensure safe operation in electrical systems and reduce risks associated with high voltage equipment. They provide operators with easy control of circuits and help prevent injury or damage due to short-circuiting or accidents. Isolators also help protect other components in a system by providing additional insulation, which can help improve efficiency and performance while reducing costs. Electrical isolators are commonly used in industrial settings where safety is paramount, but they can be used in many different applications too. [3]

Difference Between Electrical Isolator And Circuit Breaker

While electrical isolators and circuit breakers may both be found in electrical systems, they serve two very different functions. Electrical Isolators are used to completely disconnect a part of the system from the main power source, while circuit breakers protect against overloads and short circuits by automatically interrupting the current flow to prevent damage to the electrical components. In other words, an isolation device is used for safety purposes, while a circuit breaker prevents equipment from being damaged.

Circuit breakers are designed with trip settings that will open when there is too much current flowing through the circuit or when it detects an imbalance between the phase currents within a three-phase system. An isolator will not have any trip settings and simply provides separation between two parts of the system.

When it comes to reliability and safety, an electrical isolator is much more dependable than a circuit breaker. An isolator can be used when maintenance needs to be done on a part of the system, as it will provide complete disconnection from the power source, meaning that no current flow will occur while repairs are being made. Furthermore, with no trip setting, there is less chance of the equipment malfunctioning or tripping at inopportune times.

Similarities Between Isolator And Circuit Breaker

An electrical isolator and a circuit breaker are similar in that they both help to protect circuits from overloads. They are also designed to disconnect the power if there is a fault on the line or an abnormally high current flow. However, whilst a circuit breaker will automatically reset once the condition has been cleared, an isolator does not have this function and must be manually reset after each event.

In summary, while they perform similar functions, their design and application are quite different. [4]

What Is The Role Of Isolators In The Transmission Line?

Isolators are used to protect transmission lines and circuit breakers from any surge or fault in the line. They provide a safety barrier between high voltage circuits and the rest of the system. In case of a short circuit or an overload, isolators act as a switch that prevents further damage by disconnecting the affected part from the rest of the system. Isolator switches also help in sectionalizing the transmission lines into smaller parts for easier maintenance.

This reduces both downtime and repair costs due to isolated problems instead of large-scale faults across long sections of transmission line. Additionally, isolators may be employed for earthing purposes to safely dissipate static electricity build up, which can otherwise cause arcing and sparking between points on a live line. Isolator switches are essential components of electrical networks, and they continue to be crucial for the safe transmission of electricity.

How To Maintain Electrical Isolators?

Maintaining electrical isolators is important to ensure they are functioning properly and providing the necessary safety. Electrical isolators should be checked at regular intervals, and any damaged or malfunctioning parts should be replaced immediately. Here are some tips for maintaining electrical isolators:

- Check all cables regularly for wear and tear, including broken wires or exposed insulation.

- Inspect the enclosure and make sure it is not cracked or corroded.

- Ensure that all moving components move freely without any binding or friction.

- Test the insulating material of the isolation device by using a high voltage tester to verify its performance.

- If you find signs of damage, contact qualified personnel to repair or replace the device.

- Perform routine maintenance on all electrical isolators and make sure they are properly calibrated and functioning correctly.

- Make sure to keep spare isolators in case of an emergency, in order to prevent any unnecessary downtime or inconvenience.

- Store the electrical isolator in a dry, dust-free environment to avoid corrosion or other damage caused by moisture or dirt.

- Finally, ensure that all safety protocols are followed when working with electrical isolators by following manufacturer’s instructions and wearing protective clothing and equipment.

By following these tips for maintaining your electrical isolator devices, you can ensure their operation is reliable and free from faults that could potentially cause injury or harm to people or property. Additionally, following a regular maintenance schedule can help to extend the life of your electrical isolators and keep them running smoothly for years to come. [5]

Electrical Isolator For Air Conditioner

An electrical isolator is an important component of air conditioner systems, as it prevents electric current from passing between the components that make up the AC system. This greatly reduces the risk of shocks or arcing in the event of a failure. Electrical isolators are typically used to separate two different parts of an AC system, such as the compressor and condenser coils, or to prevent short circuits in case of a malfunction. They also help keep dirt and debris out of the electrical system, which can cause damage over time.

Electrical isolators come in various shapes and sizes for use with different types of AC systems and equipment. Installation should always be done by an experienced professional to ensure proper function and safety.

Applications Of Isolator Switches

Isolator switches are used to electrically disconnect loads from their power source in order to prevent electric shock, reduce the risk of fires, and protect downstream equipment. In addition to safety applications, these switches can be used to provide complete isolation of two circuits or components in an electrical system.

Isolators are commonly found in industrial or commercial settings where there is a requirement to isolate power sources such as motors and other pieces of equipment. They are also often used in hazardous locations to ensure that no accidental sparking occurs when working with flammable gasses.

In some cases, they may be deployed as part of a larger safety program that combines isolation, lockout/tagout (LO/TO), and other safety measures. This is especially true when working in hazardous or explosive areas that require additional controls.

Isolator switches are often used with motor control centers (MCCs). An MCC provides a centralized hub for the control of multiple motors while providing safety features to protect personnel from electric shock due to accidental contact with live components. Isolators play an important role in this setup by providing powerful switching capabilities and complete disconnection between the power source and load.

Types Of Functionality Devices

Electrical isolators, also known as functional devices, are used to separate electrical circuits from each other. This allows two or more circuits to be operated independently of each other, reducing the risk of accidental shorting or malfunctions. Electrical isolators come in a variety of form factors and types depending on their required functionality. These include:

- Disconnectors – Disconnectors are used to physically disconnect an electrical circuit without having to switch it off first. They allow for completely safe isolation when working with a live circuit, allowing the user to safely connect and disconnect components without fear of shock.

- Isolator Switches – These devices work similarly to standard switches but offer additional safety by providing complete insulation between all electrical contacts. This means that when the switch is in the off position, it completely breaks all contact between the circuit and anything else.

- Circuit Breakers – These devices are used to protect circuits from overloads or short circuits. They work by automatically switching the circuit off if too much current flows through it, protecting both equipment and personnel.

- Fuses – Fuses are a type of device that acts as a sacrificial link, breaking an electrical circuit when excessive current passes through them. They act as an early warning system that can help prevent damage to more expensive components by detecting dangerous levels of current before they become a problem. [6]

FAQ

When would you use an isolator?

An electrical isolator is used in a variety of applications, such as power distribution and protection, noise reduction, and safety. In power distribution or protection applications, they are typically used to control the flow of electricity between two points without allowing any current leakage. Noise reduction applications make use of them to reduce interference from other equipment or signals that may be present in the system. They can also act as a safety measure by completely disconnecting a circuit when it is no longer needed. In all cases, the goal is to isolate one element from another for optimal performance and safety.

What is the difference between switch and isolator?

A switch is a device that can be used to turn on and off an electrical circuit. An isolator, on the other hand, does not interrupt the current flow but instead prevents any current from flowing between two points by providing a complete physical separation. In this way, an isolator acts as an insulator and provides more reliable isolation of currents than a switch would. Additionally, unlike switches which require manual operation to control the flow of electricity, isolators are typically automatic and are activated through various methods such as temperature change or pressure.

What is the purpose of using an Isolator?

The main purpose of using an isolator is to provide protection against electric shock and hazardous conditions in electrical equipment or systems. Isolators also provide a physical separation between two or more circuits, which can help reduce electromagnetic interference and cross-talk between the different components. In addition to this, isolators are used for controlling the flow of electricity in power distribution systems, motor control systems, and other applications that require the isolation of one element from another. Finally, they are also commonly used in safety devices such as overload relays and circuit breakers to prevent short circuits and overloads.

What are the benefits of using an Isolator?

The primary benefit of using an isolator is its ability to provide complete protection against electric shock hazards by completely separating one element from another. This makes them an ideal choice for many applications where safety is paramount. Additionally, because they offer more reliable isolation of currents than switches, they can help to reduce electromagnetic interference and cross-talk in complex systems. Finally, isolators are also relatively easy to install and maintain, making them a cost-effective solution for many applications.

Are there any drawbacks to using an Isolator?

The main drawback of using an isolator is that they typically require a power source in order to function properly. Additionally, some types of isolators may be more prone to damage or wear due to environmental factors such as temperature changes or high levels of moisture. Finally, depending on the application, it may be necessary to use multiple isolators in order to provide complete protection against electric shock hazards. This can increase the complexity and cost of a system.

What is the difference between a breaker and an isolator?

A breaker and an isolator serve different functions in an electrical system. Breakers are designed to protect the circuit by interrupting power when it detects a short circuit or overload. Isolators, on the other hand, are used to protect people from electric shock by physically separating live parts of the circuit. In addition, they provide visual indication that a device is energized and can be used as a switch to turn off the power in order to perform maintenance or repairs. They also provide full isolation even at zero load current, whereas breakers must maintain some minimal level of contact in order to detect overcurrents. In general, breakers are better suited for protection against shorts while isolators are better suited for safety applications.

Useful Video: Isolator vs Circuit Breaker – Difference Between Isolator and Circuit Breaker

Conclusion

In conclusion, electrical isolators are essential components of any circuit. They provide a critical layer of protection between power sources and other parts of the system. By preventing direct contact with potentially dangerous voltages, an isolator helps to keep people safe from electric shock and reduce the risks associated with faulty wiring or overloaded circuits. Isolators can also help extend the life expectancy of electrical equipment by preventing interference from external sources. For these reasons, it is important to select high-quality isolators that are suitable for their intended application when designing or repairing an electrical system.

References

- https://atlas-scientific.com/blog/what-is-electrical-isolation/

- https://medium.com/everything-electrical/what-is-an-electrical-isolator-types-working-and-its-applications-b9bb13cd0cae

- https://www.elprocus.com/electrical-isolator-definition-working-types-of-isolator-applications/

- https://www.beny.com/isolator-vs-circuit-breaker/

- https://crackingenergy.com/blog/ev/guides/whats-an-isolator-switch

- https://www.watelectrical.com/electrical-isolator-working-types/

Leave a Reply