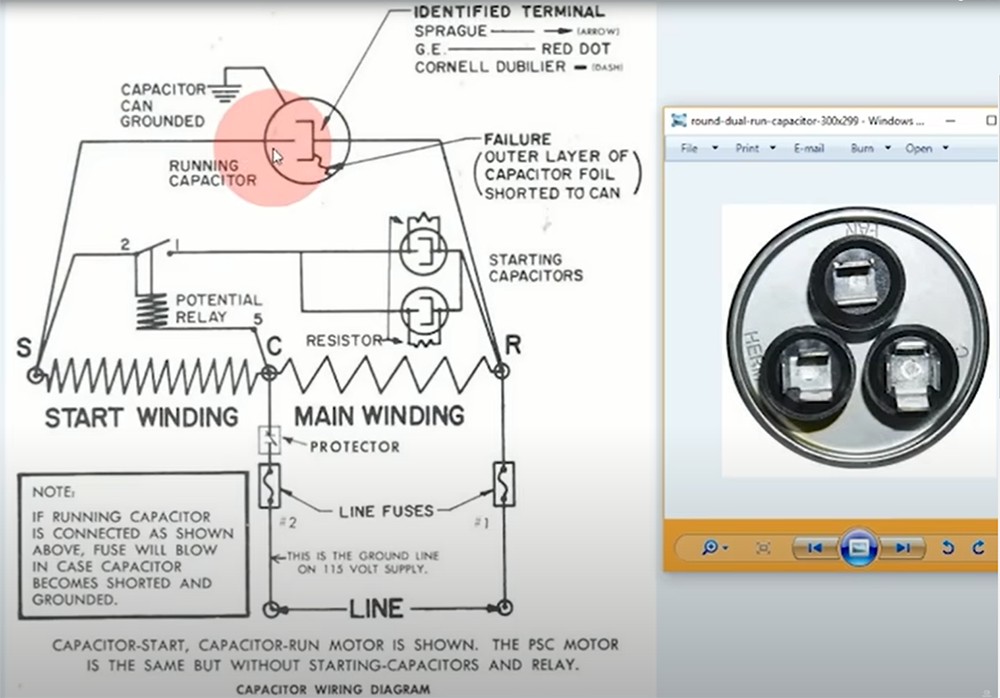

A capacitor is a device used to store an electric charge. They are commonly found in electronic circuits, and they are often necessary for the proper functioning of those circuits. Capacitors can fail for a number of reasons, but understanding the causes of failure is essential for preventing it from happening. In this article, we will discuss the most common causes of capacitor failure and provide some tips for preventing it from happening.

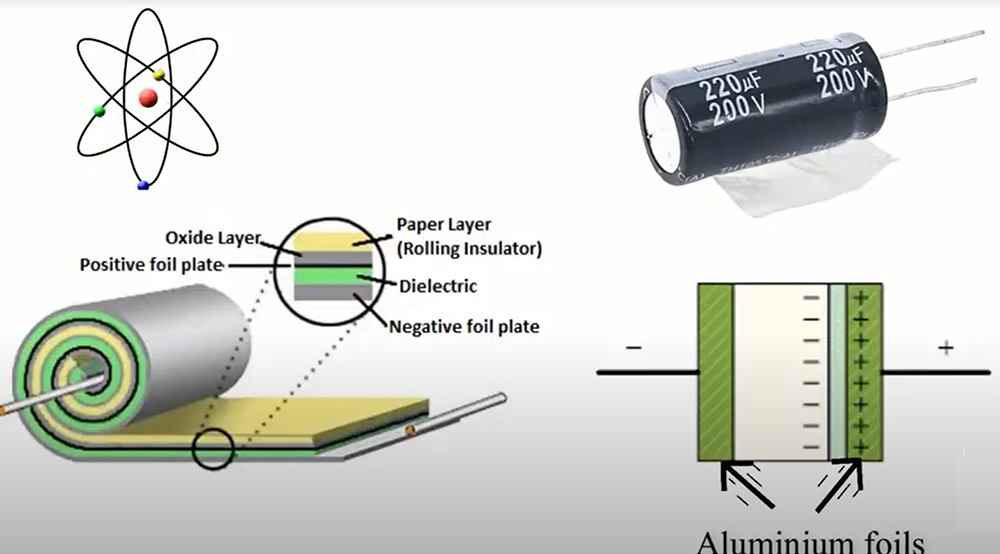

Construction of Capacitors

A capacitor is an electronic device that stores electrical energy in an electric field. Capacitors are used in a wide range of electronic devices, from cell phones to computers to radios. They are found in almost every type of electronic equipment.

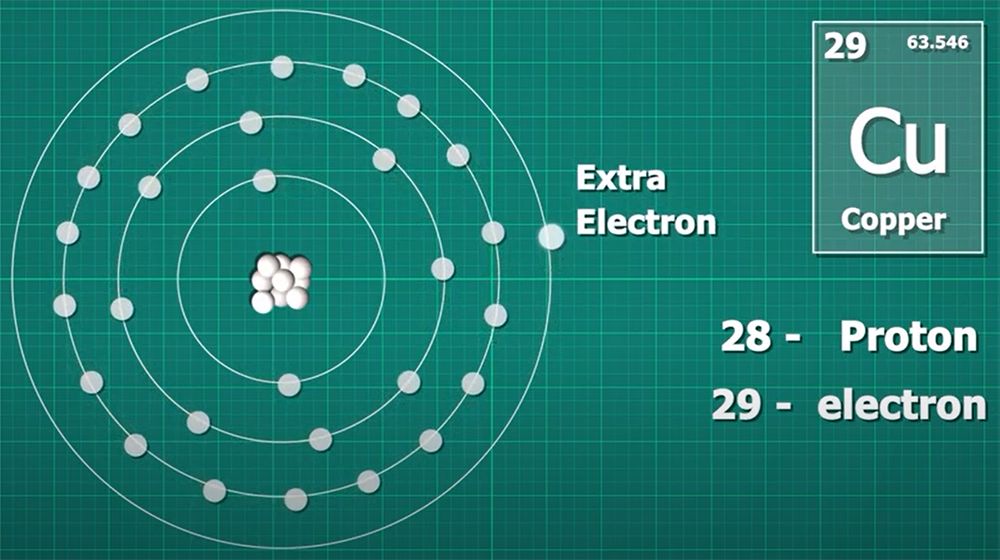

There are many different types of capacitors, but they all work on the same basic principle: two conductors separated by an insulating material (called a dielectric). When voltage is applied to the conductors, an electric field is created. This field stores energy.

The most common type of capacitor is the electrolytic capacitor. It consists of two metal plates (the conductors) separated by a layer of electrolyte (the dielectric). The electrolyte is usually an acidic solution.

When voltage is applied to the electrolytic capacitor, the electric field creates a current in the electrolyte. This current causes ions to move from one plate to the other. These ions build up on one of the plates, creating a charge. The electric field stores energy by storing this charge.

The capacitance of a capacitor is determined by the area of the plates, the distance between them, and the type of dielectric material used. The higher the capacitance, the more electrical energy the capacitor can store.

From the above you can see that capacitors are used in a wide variety of electronic devices because they can store large amounts of energy and release it very quickly. They are often used to filter signals or to provide power to electronic components. [1]

Types of Capacitor Failures

Unfortunately, just like any other electronic component, capacitors can and do fail. When a capacitor fails, it can cause all sorts of problems in the electronic device it is powering. In some cases, it can even cause the device to stop working entirely.

Dielectric breakdown

One of the most common causes of capacitor failure is dielectric breakdown. This happens when the insulation between the plates of the capacitor breaks down, allowing current to flow where it should not. This can happen due to a number of factors, including voltage spikes, excessive heat, or physical damage to the capacitor.

Dielectric breakdown is usually irreversible, which means that once it happens, the capacitor needs to be replaced. However, there are some types of capacitors that can be repaired if they have not been damaged too badly.

If you suspect that your capacitor has suffered from dielectric breakdown, take it to a qualified electronics technician for further testing and replacement if necessary.

Open capacitors

Another common type of capacitor failure is an open capacitor. This occurs when one of the plates of the capacitor becomes detached from the others. This can happen due to a manufacturing defect, physical damage, or corrosion.

Open capacitors are usually irreparable and need to be replaced. However, if the capacitor undergoes too much physical stress, it can cause the entire capacitor to break apart. In this case, it is best to discard the capacitor and replace it with a new one. [2]

Factors That Can Cause Damage to Capacitors

Now that we’ve gone over the two most common types of capacitor failure, let’s discuss some of the factors that can cause damage to capacitors. There are actually quite a few!

Capacitance

Rapid changes in capacitance can cause damage to a capacitor. For example, if a capacitor is charged and discharged very rapidly, the clamping pressures inside the capacitor can become too high, causing the capacitor to fail.

Humidity

Another factor that can cause damage to a capacitor is humidity. When capacitors are exposed to high levels of humidity, it can cause the dielectric material to break down. This breakdown can eventually lead to capacitor failure.

Humidity can also cause corrosion on the electrode terminals, which can lead to increased resistance and eventual failure.

Corrosion is not only caused by exposure to moisture, but also by certain chemicals in the atmosphere, such as sulfur dioxide and chlorine. These chemicals can react with the metal electrodes and cause corrosion.

Capacitors that are used in outdoor applications are especially susceptible to damage from humidity and corrosive chemicals. That’s why it’s important to use capacitors that are rated for use in harsh environments.

High temperatures

Obviously, one of the main things that can damage any electronic component is high temperatures. This is especially true for capacitors, since they often need to operate at very high temperatures in order to function properly.

One way to prevent this type of damage is to make sure that you don’t exceed the maximum operating temperature of the capacitor. Second, use thermal management techniques to keep the capacitor cool. This can include anything from using a heatsink to placing the capacitor in an area with good airflow.

Life in service

Just like any other electronic component, capacitors have a finite lifespan. The electrolyte in an aluminum electrolytic capacitor will evaporate over time, causing the capacitor to dry out and eventually fail.

The amount of time it takes for this to happen varies depending on the quality of the capacitor and the conditions under which it is used. For example, a high-quality capacitor used in ideal conditions (low temperature, low humidity, etc.) can last for years. On the other hand, a lower-quality capacitor used in harsher conditions (high temperature, high humidity, etc.) may only last for a few months.

Dissipation factor

The next factor we’ll discuss is the dissipation factor. Dissipation factor is a measure of how much energy is lost in a capacitor as heat. The higher the dissipation factor, the more likely it is for the capacitor to fail.

There are two main reasons why dissipation factors can cause capacitor failure. First, if the dissipation factor is too high, the capacitor will overheat and eventually catch fire. Second, if the dissipation factor is too high, the capacitor will lose its ability to hold a charge. This can cause all sorts of problems, including reduced performance and even complete failure.

Insulation resistance

Insulation resistance is a measure of how well the dielectric material (the insulator) between the capacitor’s plates can resist the flow of current. If the insulation resistance is too low, current will flow through the dielectric material and cause it to break down. This will eventually lead to a short circuit and failure of the capacitor.

There are a few things that can cause low insulation resistance in capacitors. One is contamination of the dielectric material by particles of dust or other contaminants. Another is exposure to high temperatures, which can cause the dielectric material to deteriorate over time. Finally, voltage stress can also reduce insulation resistance. When a capacitor is exposed to a voltage that is too high for its rating, the electric field in the dielectric material can become strong enough to cause current to flow through it.

Sealing quality

For example, while hermetically sealed capacitors are designed to be highly resistant to moisture and contamination, the internal pressure within the capacitor can raise with temperature changes. If the pressure exceeds the strength of the seals, moisture can enter the capacitor and cause it to fail.

Epoxy sealed capacitors on other hand, have a lower resistance to moisture and contamination. The sealing process is not as reliable, which can result in capacitors that fail prematurely.

To avoid this type of failure, it’s important to use capacitors from a reputable manufacturer that uses high-quality materials and has strict quality control procedures in place.

Dielectric strength

Dielectric strength can also affect the reliability of capacitors. The dielectric strength of a material is basically a measure of how well it can withstand being charged and discharged.

As you can imagine, the higher the dielectric strength of a capacitor’s dielectric, the longer it will last. Unfortunately, there are many materials out there with relatively low dielectric strengths. This includes some plastics and even some types of glass.

If you’re using capacitors in an application where they will be subject to high voltages or currents, it’s important to use ones with high quality dielectrics. Otherwise, you run the risk of them failing prematurely.

Vibration and shock

Another two factors that can affect the reliability of capacitors are vibration and shock. While most capacitors are designed to withstand a certain amount of vibration and shock, they can still be damaged by excessive amounts.

This can happen during shipping, installation, or operation. Even small amounts of vibration can cause internal damage to the capacitor, resulting in a loss of capacitance or an increase in leakage current. In extreme cases, vibration can even cause the capacitor to fail catastrophically.

Capacitors are also susceptible to impact damage from things like tools or other objects falling on them.

Barometric pressure

Another environmental factor that can affect the reliability of capacitors is barometric pressure. This is the atmospheric pressure that exists at a particular location. When this pressure changes, it can put stress on the capacitor’s internal components, which can lead to failure. Barometric pressure isn’t something that we can control, so it’s important to make sure that our capacitors are rated for the range of pressures that they may experience in their environment.

Radiation

While not as common as other causes, radiation can damage or destroy capacitors. This is usually only a problem for capacitors that are used in aerospace or military applications. The most common type of radiation that damages capacitors is called single event upset (SEU). SEU is caused by high-energy particles, such as cosmic rays, hitting the capacitor’s dielectric material. This can cause the material to become polarized, which in turn causes the capacitor to fail. [2], [3]

FAQ

How do you prevent a capacitor from failing?

There are a few things you can do to prevent capacitors from failing:

- Use high-quality capacitors that are designed for the application and environment

- Keep capacitors away from heat sources

- Avoid using damaged or corroded parts

- Inspect capacitors regularly for signs of failure. If a capacitor is showing signs of failure, replace it before it fails completely.

What causes a capacitor to burn out?

There are many reasons why a capacitor can burn out. The most common reason is because of an electrical surge. This can happen if there is a power outage or if the power supply to the capacitor is interrupted. Other causes of capacitors burning out include, but are not limited to: overheating, excessive current, voltage spikes.

What is the common fault of a capacitor?

The most common faults of capacitors are shorts and leaks. These can be caused by a number of factors, including manufacturing defects, damage during installation, or exposure to extreme temperatures.

How many years can a capacitor last?

The lifespan of a capacitor can vary greatly depending on the quality of the capacitor, as well as the operating conditions and environment. Capacitors used in less demanding applications, such as in power supplies for consumer electronics, can last for over ten years. Meanwhile, capacitors used in more demanding industrial applications may only last a few years before needing to be replaced.

Useful Video: Why Do Capacitors Fail? (It’s not why you think)

Conclusion

Capacitors are an essential part of any electronic device, and their failure can lead to some serious consequences. In this article, we’ve looked at some of the most common causes of capacitor failure, as well as some tips on how to prevent it. There are many different reasons why capacitors might fail. The most common reason is simply age. Over time, the dielectric material breaks down and becomes less effective at storing electrical energy. Exposure to extreme temperatures can also cause capacitors to fail. And same goes for humidity, which can cause the capacitor’s electrodes to corrode. Improper handling and installation can also lead to capacitor failure. Finally, overloading a capacitor can cause it to fail. This is why it’s important to always follow the manufacturer’s instructions when using capacitors.

If you suspect that your capacitor may be failing, it’s important to contact a qualified technician as soon as possible. With proper care and maintenance, your capacitors should last for many years. Thanks for reading!

References:

- https://electronics.howstuffworks.com/capacitor.htm

- https://www.electrocube.com/pages/why-capacitors-fail-technical-bulletin

- http://www.electricalterminology.com/causes-of-capacitor-failure/

Leave a Reply