Welding and soldering are both forms of metal joining. They both use heat to fuse two pieces of metal together, but the process and results are quite different. So can you weld with a soldering iron? The answer is complicated. In this article, we’ll discuss the basics of welding and soldering, and give you some tips on how to get the best results if you’re trying to weld with a soldering iron.

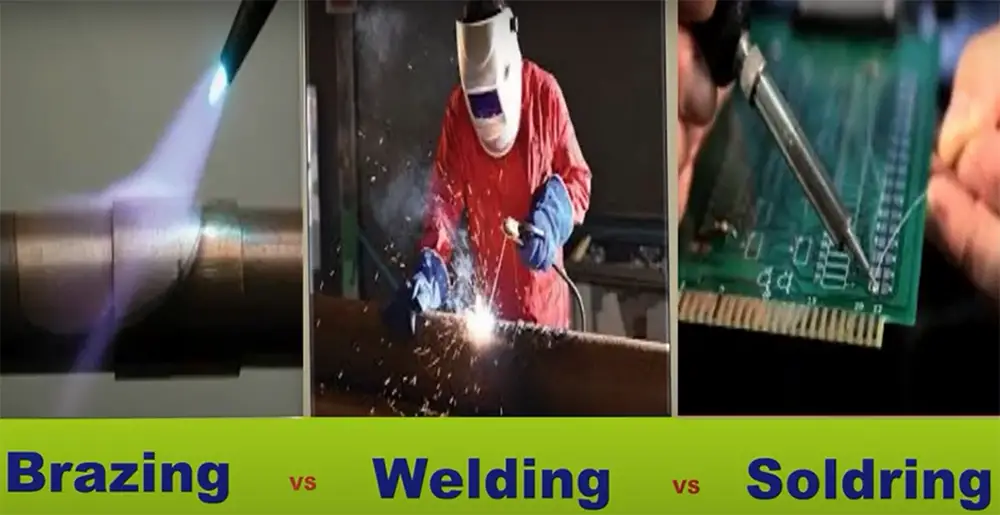

Difference Between Welding, Brazing and Soldering

A soldering iron is a hand tool used in soldering. It consists of a metal tip that heats up when electrically charged and melts the solder to join two pieces of metal together, as well as a handle to grip it with. So why would you want to weld with a soldering iron? In some cases, it might be the only option available to you. For example, if you need to weld two pieces of metal together but don’t have access to a welder, using a soldering iron might be your only choice.

Before we get into whether or not you can weld with a soldering iron however, it’s important to understand the difference between welding, brazing and soldering.

What is welding

Welding is a process of joining two pieces of metal together by using heat and pressure. The heat melts the metal, which allows it to flow and fuse together. Once the metal cools and hardens, you’re left with a strong joint that can withstand a lot of force.

The filler material is often added to the weld to help strengthen it even more and fill all the gaps. This is especially important when welding two dissimilar metals together, as it helps to prevent corrosion.

There are many different types of welding, but some of the most common are arc welding, oxy-acetylene welding, and spot welding.

Welding is done at high temperatures, typically over 1500 degrees Fahrenheit. This high heat melts the base metals and filler material, which fuse together when cooled. Welding is also generally considered to be a more difficult process than soldering, so if you’re new to metalsmithing or fabrication, it’s probably best to stick with soldering for now.

There are a variety of welding methods out there. Gas metal arc welding is the most common type, which uses an electrode that’s fed through a welding torch to create the arc.

SMAW, or stick welding, is another popular method that uses an electrode that’s attached to a power source. The heat from the arc melts the metal, which fuses the two pieces together.

GTAW, or TIG welding, is a bit more complicated. This method uses a non-consumable electrode that’s fed through a welding torch. The heat from the arc melts the metal, which fuses the two pieces together.

MIG welding, or wire welding, is similar to GTAW but uses a consumable electrode that’s fed through a welding torch. The heat from the arc melts the metal, which fuses the two pieces together. [1], [4]

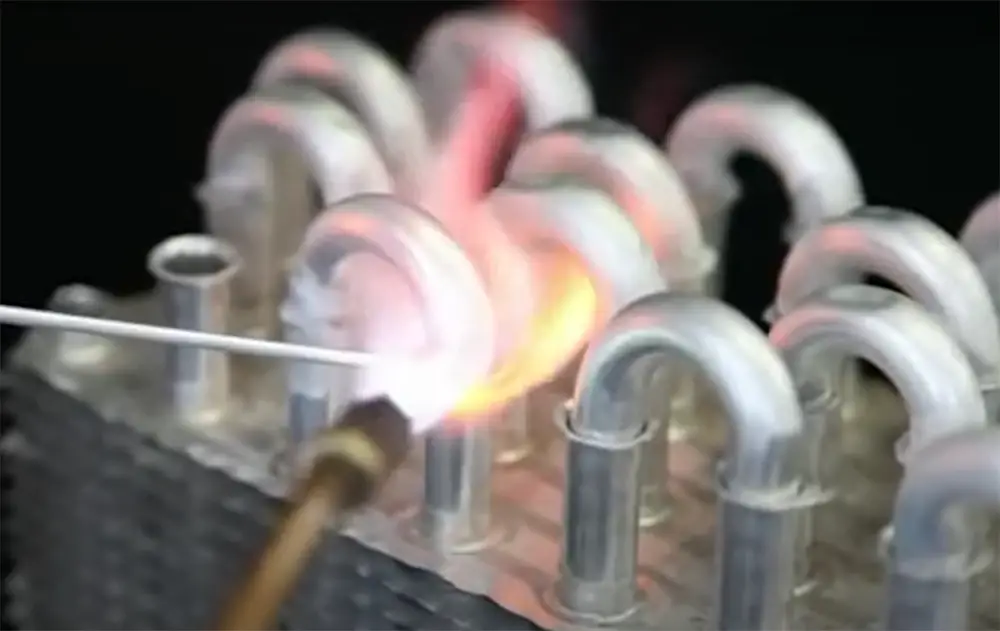

What is brazing

Now let’s talk about brazing. Brazing is a process where two pieces of metal are joined together using a filler metal (solder). A solder is a fusible metal alloy used to create a permanent bond between two pieces of metal. The filler metal has a lower melting point than the base metals being joined, so it can be melted and drawn into the joint by capillary action. Brazing can be used to join dissimilar metals and is often used in plumbing and electrical applications.

Brazing is similar to welding but there’s a major difference between the two, as brazing doesn’t involve melting the base metals. This means that the joint won’t be as strong as a welded joint, but it will be able to withstand some force. [1]

What in soldering

Soldering is a process in which two or more pieces of metal are joined together by melting and flowing a filler metal into the joint. It is very similar to brazing, but the filler metal has an even lower melting point. This means, soldering generally doesn’t use as much heat as welding, so it’s less likely to warp or damage the base metals.

Soldering is also a good choice for joining two pieces of metal together if you don’t want to damage or melt the base metals.

Just as with welding and brazing, there are different types of soldering. The soldering methods are identified by their major alloying element. For example, there are tin-based solders, lead-based solders, and aluminum-based solders.

Each type of soldering has its own advantages and disadvantages, so it’s important to choose the right one for your project. [1], [4]

So Can You Weld Using Soldering Iron?

Now that we’ve covered the basics of welding and soldering, let’s answer the question: can you weld with a soldering iron?

The answer is… no. Welding requires heat and pressure, which a soldering iron cannot provide. However, you can use a soldering iron to solder smaller metals together. Soldering is not as strong as welding, but it can be used for smaller projects or projects that do not require as much strength. It’s definitely not recommended for any applications where the joint will be subject to high stresses or temperatures.

You technicialy can use a soldering iron for welding if you’re working with very thin pieces of metal. Welding with a standard welder can often cause the metal to warp or distort, but using a soldering iron can help prevent that. [1], [2]

Welding Plastic With Soldering Iron

While you can’t weld metals together using a soldering iron, you can weld plastic. This process is known as plastic welding, and it can be useful for repairing everything including cracked plastic parts. To weld plastic together using a soldering iron, you’ll need to purchase a few supplies. In addition to a soldering iron and some solder, you’ll need a piece of scrap plastic. This will be used to test the welding process before you attempt it on the actual broken piece. You’ll also need acetone or another type of plastic solvent, as well as some sandpaper. Now that you have all of the necessary supplies, follow the steps below to weld plastic together using a soldering iron.

Clean the plastic surface

The first step is to clean the plastic surfaces that you’ll be welding. Any dirt, grease, or other contaminants will weaken the weld. Use a paper towel or cloth to remove any dirt, grease, or debris from the surface. You can also use a mild solvent such as rubbing alcohol to clean the plastic if needed. Once the surfaces are clean, roughen them up a bit with sandpaper so that the solder will have something to grip onto. All this will help the weld to adhere properly.

Warm up the soldering iron

If you don’t have a way to measure the temperature, just wait until the tip of the soldering iron is hot enough that it melts a small piece of plastic.

Run soldering iron across the seams

Once the soldering iron is hot enough, you can start welding the plastic. Grab two pieces of plastic that you want to weld together. Place the soldering iron against the seam and run it along the length of the seam. The heat from the soldering iron will melt the plastic, and as you move it along, the molten plastic will weld together.

Continue running the soldering iron along the seam until you’ve gone all the way around. You may need to make a few passes to get a strong weld.

Adjust the pieces

Keep in mind that you’ll need to hold the pieces of plastic together while you’re welding them. This can be a bit tricky, so you may need to adjust the position of the pieces as you go. Once you’ve made a few passes with the soldering iron, stop and check to see how well the weld is holding. If it’s not holding well, try adjusting the position of the pieces and welding again.

Finish with swift strokes

As you get close to the end of the seam, you’ll want to make sure that you finish with a few swift strokes. This will help to ensure that the ends of the weld are strong.

Let it cool

Once you’re done welding, allow the plastic to cool completely before handling it. And that’s all there is to welding plastic with a soldering iron! As you can see, it’s not too difficult, and it can be a great way to repair cracked or broken plastic parts. Just remember to use caution when handling the hot soldering iron, and be sure to let the weld cool completely before using the repaired item.

FAQ

What kind of solder do you use for steel?

You don’t really need to use a special kind of solder when welding steel with a soldering iron. However we recommend you go with a tin-based solder because it will flow more easily and create a stronger bond.

Can you use soldering to weld steel?

The quick answer is no. You can not use a soldering iron to weld steel. The soldering iron will simply not be able to generate enough heat to weld steel. You can weld it only if you reach the temperature required for welding, which is around 1500 degrees Fahrenheit.

How do you bond metal without welding?

If you’re looking to bond metal without welding, there are a few different options available to you. One option is to use an adhesive specifically designed for bonding metal. There are also some types of epoxy that can be used for this purpose. Another option is to use mechanical fasteners, such as screws or bolts, to join the two pieces of metal together.

Useful Video: Best Soldering and Mini welding tool- How to Make 12v Welding

Final words

As you can see, it’s generally not possible to weld with a soldering iron. The temperatures just aren’t high enough. However, you can do some brazing and light metal work if you have the right tools and materials. Just be mindful of the limitations of your tools and always stay safe when working with hot metals! We hope this guide was helpful. If you have any questions, feel free to leave a comment below or contact us directly. Thanks for reading!

References:

- https://electronicguidebook.com/can-you-weld-with-a-soldering-iron/

- https://welderacademy.com/can-you-weld-with-a-soldering-iron/

- https://www.circuitspecialists.com/blog/welding-plastic-with-soldering-iron/

- https://handtoolsforfun.com/can-you-weld-with-a-soldering-iron/

In my view, the distinction between soldering and welding is clear. Soldering, performed with a soldering iron, is suitable for lightweight, precision work, but it lacks the strength and durability of welding. While it may work for thin metal pieces, it’s not recommended for applications under high stress or temperature conditions. Each method has its purpose, and it’s essential to choose the right one for your specific project.

In my view, the distinction between soldering and welding is clear. Soldering, performed with a soldering iron, is suitable for lightweight, precision work, but it lacks the strength and durability of welding. While it may work for thin metal pieces, it’s not recommended for applications under high stress or temperature conditions. Each method has its purpose, and it’s essential to choose the right one for your specific project.

Leave a Reply