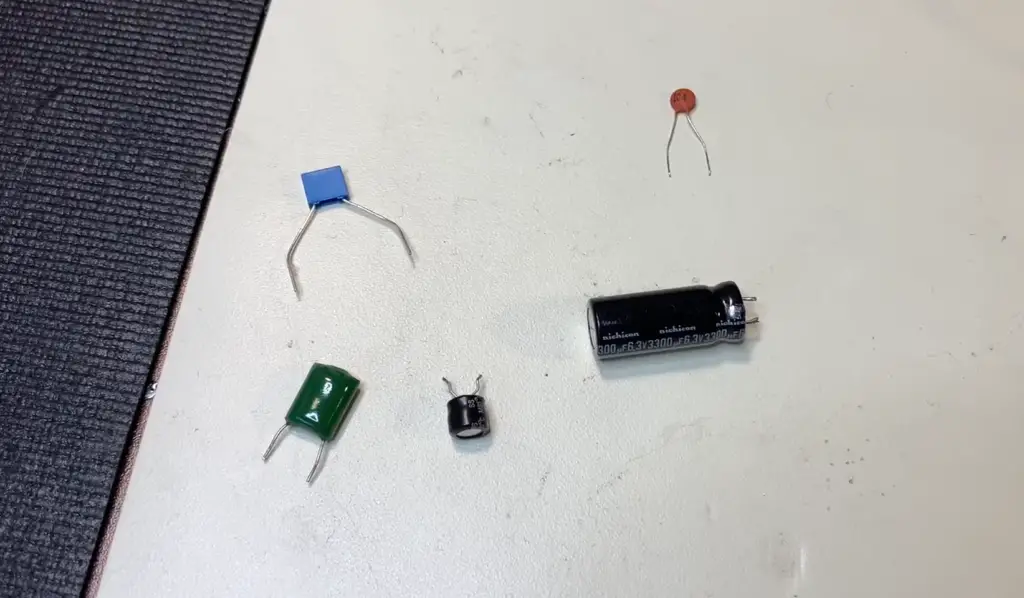

Capacitors are essential components in electronic circuits, performing crucial functions such as energy storage, filtering, and signal coupling.

As these components work, it is natural to wonder if they generate heat. The answer is yes, capacitors can get hot during operation, particularly when subjected to high currents, high frequencies, or excessive voltage stress.

Heat generation in capacitors can occur due to factors such as resistive losses, dielectric losses, or internal component inefficiencies. Understanding why capacitors get hot and how to manage their heat is crucial for ensuring optimal performance, reliability, and safety in electronic systems.

In this article, we will explore the reasons behind capacitor heating, the effects of excessive heat, and strategies to mitigate potential issues.

Major Capacitor Characteristics:

Nominal Capacitance

The nominal capacitance of a capacitor refers to its rated capacitance value. It represents the amount of electrical charge the capacitor can store when a specified voltage is applied across its terminals.

Capacitance is measured in Farads (F) or its subunits such as microfarads (µF), nanofarads (nF), or picofarads (pF). Capacitors with higher capacitance values can store more charge and are suitable for applications requiring larger energy storage [1].

Working Voltage

Exceeding the working voltage can lead to capacitor failure, including leakage or even explosion. When selecting a capacitor, it is essential to choose one with a working voltage higher than the maximum voltage it will encounter in the circuit.

Tolerance

Capacitors, like many electronic components, have manufacturing tolerances that define the acceptable deviation from the nominal value. Tolerance indicates the accuracy of the capacitor’s capacitance rating.

For example, a capacitor with a nominal capacitance of 10 µF and a tolerance of ±10% may have an actual capacitance between 9 µF and 11 µF. Tighter tolerance capacitors are typically more expensive but offer greater precision in circuit design.

Leakage Current

Leakage current refers to the small amount of current that flows through a capacitor even when it is fully charged. It occurs due to imperfections in the dielectric material and can cause energy loss and affect circuit performance. Low leakage capacitors are crucial in applications where energy efficiency is essential, such as battery-powered devices or low-power circuits.

Working Temperature

The working temperature range indicates the temperatures within which a capacitor can reliably operate. Extreme temperatures can adversely affect a capacitor’s performance, including changes in capacitance, leakage current, and even physical damage. It is crucial to choose capacitors designed for the specific temperature conditions of the application environment.

Temperature Coefficient

The temperature coefficient of a capacitor indicates how its capacitance value changes with temperature. It quantifies the rate of change in capacitance per degree Celsius. Capacitors with a positive temperature coefficient have their capacitance increase as the temperature rises, while those with a negative coefficient experience a decrease. This characteristic is important in applications where temperature variations can impact circuit performance.

Polarization

Certain types of capacitors, such as electrolytic and tantalum capacitors, are polarized, meaning they have a designated positive (+) and negative (-) terminal [2]. Applying voltage in the wrong polarity can lead to catastrophic failure, including leakage, explosion, or venting of corrosive materials. Non-polarized capacitors, like ceramic and film capacitors, do not have polarity restrictions.

Equivalent Series Resistance (ESR)

ESR refers to the resistance encountered by an ideal capacitor when subjected to alternating current (AC). It arises due to the internal resistance of the capacitor and is responsible for energy loss and heating. High ESR can affect the stability and efficiency of a circuit, particularly in applications that require low impedance or high-frequency response.

Why Do Capacitors Fail?

Dielectric Breakdown

Dielectric breakdown occurs when the insulating material, known as the dielectric, inside a capacitor fails to withstand the applied voltage. This can happen due to excessive voltage spikes, overvoltage conditions, or manufacturing defects.

Open Capacitors

Open capacitors refer to capacitors that develop an open circuit, resulting in a complete loss of functionality. This failure can be caused by aging, mechanical stress, thermal expansion and contraction, or improper soldering. Open capacitors exhibit infinite resistance and fail to store or release electrical energy, disrupting the circuit’s operation.

Environmental Considerations

Environmental factors such as temperature, humidity, and exposure to chemicals can significantly impact capacitor performance and lifespan. Extreme temperatures can cause thermal stress, leading to solder joint failures or changes in the capacitor’s characteristics. High humidity levels can cause corrosion, affecting the integrity of the capacitor’s terminals and connections. Chemical exposure, such as exposure to solvents or contaminants, can degrade the dielectric material, leading to reduced capacitance or short circuits.

Service Life

Capacitors have a finite service life, which is influenced by various factors, including temperature, voltage stress, and operating conditions. Electrolytic capacitors, for example, have a limited lifespan due to the gradual degradation of their electrolyte. Operating capacitors beyond their expected service life can result in increased failure rates and reduced performance.

Capacitance

Over time, capacitors can experience changes in their capacitance values. This can occur due to aging, temperature variations, or voltage stress. Capacitors with reduced capacitance may not provide the expected energy storage or filtering capabilities, leading to circuit malfunctions. On the other hand, capacitors with increased capacitance may affect the circuit’s timing or cause stress on other components.

Insulation Resistance

Insulation resistance refers to the resistance between a capacitor’s terminals and its dielectric material. A decrease in insulation resistance can occur due to aging, humidity, or contaminants. Reduced insulation resistance can lead to leakage currents, energy losses, or short circuits, compromising the capacitor’s performance and potentially damaging the circuit.

Dissipation Factor

The dissipation factor, also known as the loss tangent, measures the amount of energy lost as heat in a capacitor. It represents the ratio of the capacitor’s equivalent series resistance (ESR) to its capacitive reactance. A high dissipation factor indicates increased energy losses and can be caused by factors such as high operating frequencies, temperature, or capacitor aging. High dissipation factors can lead to reduced efficiency, overheating, and premature failure.

Dielectric Strength

Dielectric strength refers to the maximum voltage a capacitor’s dielectric can withstand without experiencing breakdown. If the voltage exceeds the dielectric strength, it can lead to insulation failure, arcing, or short circuits. Properly selecting capacitors with appropriate dielectric strength for the specific voltage requirements is crucial to avoid failures [3].

Sealing

Some capacitors, especially electrolytic capacitors, require hermetic sealing to protect their internal components from moisture or contaminants. If the sealing is compromised, either during manufacturing or due to physical stress, it can result in moisture ingress, which can lead to corrosion, short circuits, or changes in capacitance.

Vibration, Acceleration & Shock

Capacitors may experience mechanical stress due to vibration, acceleration forces, or shock in certain applications. Excessive mechanical stress can cause solder joint failures, cracks in the dielectric, or internal component displacement, leading to circuit interruptions or reduced capacitor performance.

Barometric Pressure

In applications where barometric pressure variations are significant, such as aerospace or high-altitude environments, the pressure differential can affect the performance of certain capacitors. It is crucial to choose capacitors specifically designed to withstand the pressure conditions to avoid failures.

Radiation

In radiation-rich environments, such as nuclear power plants or space applications, radiation can degrade the performance of capacitors. Ionizing radiation can cause charge trapping, increased leakage currents, or changes in the dielectric properties, leading to circuit failures. Selecting radiation-hardened capacitors is essential for such demanding applications.

Failure Rate Determination

Determining the failure rate of capacitors involves considering various factors, including the capacitor’s quality, operating conditions, stress levels, and application requirements. Manufacturers provide failure rate specifications, such as the MIL-HDBK-217 or Telcordia SR-332 standards, to estimate the expected failure rates based on these factors [4]. Understanding the failure rate helps in selecting reliable capacitors for critical applications.

The Average Temperature Range Of Regular Capacitors

The temperature range of regular capacitors can vary depending on the type, manufacturer and specific application. In general, most regular capacitors can operate effectively within a temperature range of about -55°C (32F) to +125°C (257F) [5]. However, some capacitors may have narrower or wider temperature ranges depending on their construction and intended application. It is important to consult the datasheet for the specific capacitor in question to determine its temperature range and ensure it is suitable for the intended application.

Why Does Overheating Of a Capacitor Matter?

Capacitors are integral components in electronic circuits, performing various functions such as energy storage, filtering, and coupling.

However, excessive heat can have detrimental effects on capacitors and the overall performance and reliability of the circuit:

Capacitance Changes

One of the primary concerns when a capacitor overheats is the potential alteration in its capacitance value. Capacitance refers to the ability of a capacitor to store electrical charge, and it is directly related to the surface area of the capacitor plates, the distance between them, and the characteristics of the dielectric material.

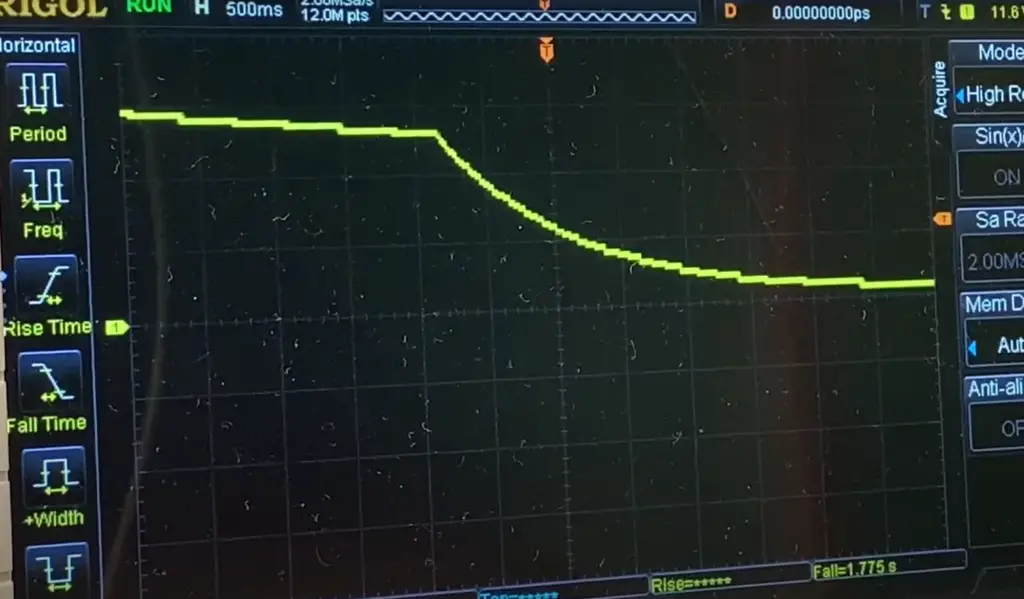

When a capacitor experiences high temperatures, the dielectric material can degrade or change its properties, leading to a deviation from the capacitor’s nominal capacitance. This alteration in capacitance can affect the overall functionality and performance of the circuit, potentially leading to incorrect voltage or timing calculations.

Increased Leakage Current

Overheating can also result in an increase in the leakage current of a capacitor. Leakage current refers to the small amount of current that flows through a capacitor even when it is fully charged. When a capacitor overheats, the dielectric material may become less effective in insulating the charge, leading to higher leakage currents.

Increased leakage currents can result in energy losses, reduced efficiency, and, in extreme cases, thermal runaway, where the heat generated by the leakage current exacerbates the overheating issue. This can compromise the stability and reliability of the circuit, especially in applications that require low power consumption or long-term energy storage.

Reduced Lifespan

Capacitors are designed with specific operating temperature ranges in mind. Exposing a capacitor to temperatures beyond its recommended range or subjecting it to prolonged periods of high temperatures can significantly impact its lifespan.

High temperatures can accelerate the aging process of the capacitor’s components, leading to the deterioration of its dielectric material, degradation of internal connections, or increased resistance in the capacitor’s leads. As a result, the capacitor may fail prematurely, leading to costly replacements or system downtime.

Internal Component Damage

Overheating can cause internal damage to the components within a capacitor. Capacitors consist of various materials, such as metallic plates, dielectric layers, and electrolytes in the case of electrolytic capacitors.

When exposed to high temperatures, these materials can expand or contract at different rates, leading to mechanical stress, cracks, or even delamination. Such internal damage can impair the capacitor’s performance, reduce its reliability, and increase the likelihood of catastrophic failures, including short circuits or explosions.

Impact on Surrounding Components

Overheating of a capacitor can have a cascading effect on the surrounding components in a circuit. Excessive heat can transfer to neighboring components, potentially affecting their performance and lifespan. Sensitive components such as integrated circuits (ICs) or transistors may experience accelerated aging or thermal stress, leading to increased failure rates or erratic behavior. This can result in system malfunctions, unexpected shutdowns, or even permanent damage to the entire circuit.

Safety Concerns

In extreme cases, overheating of a capacitor can pose safety risks.

What To Do If Your Capacitor Is Getting Hot?

Capacitors play an important role in the operation of many electronic devices, but they can sometimes become overheated and fail, leading to a potential loss of power and reduced performance. Understanding what to do if your capacitor is getting hot can help you prevent further damage and ensure the continued function of your electronic device.

The first step to take if you notice that your capacitor is getting hot is to immediately turn off the device and unplug it from the outlet. This will prevent further overheating and potential damage to other components. It is important to let the capacitor cool down before attempting to troubleshoot the issue further.

Once the capacitor has cooled down, there are a few steps you can take to diagnose and address the issue. One possible cause of overheating capacitors is an insulation breakdown, which can occur when the voltage is too high or there is a fault in the circuit [6]. In such cases, it is important to inspect the capacitor for any visible signs of damage, such as bulges, cracks, or leaks. If any damage is detected, the capacitor should be replaced with a new one.

Another possible cause of overheating capacitors is inadequate cooling or poor air circulation around the electronic device. This can cause the capacitor to become too hot, and can potentially lead to other components becoming damaged or failing. In such cases, it may be necessary to improve the airflow around the device by installing additional fans, or by moving it to a cooler location. You may also consider adding heat sinks to the capacitor, which can help dissipate heat more efficiently.

If the overheating persists after all the above-mentioned solutions have been implemented, there are a few other options. If the capacitor is accompanied by other paralleled capacitors, it is possible that the capacitors are not well matched or have increased internal resistance. This can cause one of them to become overheated. In this case, it may be necessary to replace all capacitors in the circuit with matched replacements.

Finally, if the cause of the overheating cannot be determined, it is recommended to consult a professional technician or an engineer for further diagnostics and repairs.

FAQ:

1. Do capacitors need cooling?

In general, capacitors do not require active cooling unless they are operating under extreme conditions or in high-power applications. Capacitors are designed to dissipate heat naturally through their body or through the circuit board they are mounted on.

However, in certain situations where capacitors are subjected to high temperatures, high-frequency operation, or prolonged high-power loads, additional cooling measures such as heat sinks or fans may be necessary to prevent overheating and ensure optimal performance and longevity.

2. How much heat can capacitors take?

The maximum allowable temperature for capacitors depends on their type and construction. Different capacitor technologies have varying temperature tolerances.

Electrolytic capacitors, for example, typically have temperature limits ranging from 85°C (185F) to 125°C (257F). Ceramic capacitors can handle higher temperatures, often exceeding 125°C (257F) [7].

It is essential to consult the datasheet or manufacturer’s specifications for each specific capacitor to determine its maximum temperature rating.

3. Why do capacitors overheat?

There are several reasons why capacitors may overheat. Some common causes include excessive voltage stress, high ripple currents, overloading, prolonged operation at or beyond their maximum temperature limits, poor thermal management, or manufacturing defects.

Overheating can lead to a degradation of the dielectric material, increased leakage currents, changes in capacitance, internal component damage, and, in extreme cases, thermal runaway or catastrophic failure.

4. Can a capacitor catch fire?

While it is uncommon, under certain circumstances, capacitors can catch fire. Electrolytic capacitors, in particular, are more susceptible to this risk. If operated at voltages above their rated limits, exposed to high temperatures, or subjected to extreme conditions, the electrolyte within the capacitor can break down and release flammable gases. The combination of flammable gases and an ignition source can result in a capacitor catching fire.

However, it is important to note that with proper usage and adherence to recommended operating conditions, the risk of capacitors catching fire is extremely low.

5. Is it OK to touch a hot capacitor?

No, it is not recommended to touch a hot capacitor. Capacitors can become hot during operation due to heat dissipation or high currents flowing through them. Touching a hot capacitor can lead to burns or electric shock. It is advisable to allow capacitors to cool down before handling them to ensure personal safety.

6. Can capacitors last 40 years?

The lifespan of capacitors depends on various factors, including the type of capacitor, operating conditions, temperature, voltage stress, and manufacturing quality. While some capacitors can indeed last 40 years or more, it is not a guarantee for all capacitors.

Electrolytic capacitors, for example, have a limited lifespan due to the gradual degradation of their electrolyte. Ceramic capacitors, on the other hand, can have a longer lifespan [8].

Proper selection, appropriate operating conditions, and regular maintenance are essential in maximizing the longevity of capacitors.

7. Are capacitors heat-sensitive?

Yes, capacitors are sensitive to heat. Excessive heat can affect the performance, reliability, and lifespan of capacitors. High temperatures can lead to changes in capacitance values, increased leakage currents, degradation of dielectric materials, internal component damage, and reduced overall efficiency. It is crucial to operate capacitors within their specified temperature limits to avoid adverse effects and ensure optimal performance.

8. Why is AC not used in capacitors?

Capacitors can be used in alternating current (AC) circuits. In fact, capacitors play a crucial role in AC applications, such as power factor correction, coupling, or filtering. AC signals cause the charges to continuously alternate back and forth across the capacitor plates [9]. Capacitors are specifically designed to handle these alternating voltages and effectively store and release charge accordingly.

9. Can capacitors be damaged by heat?

Yes, capacitors can be damaged by excessive heat. High temperatures can lead to the degradation of the dielectric material, increased leakage currents, changes in capacitance, internal component damage, and reduced overall performance and lifespan. It is important to operate capacitors within their specified temperature limits to avoid detrimental effects and ensure their reliability.

10. How hot do electrolytic capacitors get?

The operating temperature of electrolytic capacitors depends on their design and specifications. Standard aluminum electrolytic capacitors typically have temperature ratings ranging from 85°C (185F) to 125°C (257F) [10].

However, some specialized electrolytic capacitors, such as those designed for high-temperature applications, can withstand temperatures up to 150°C (302F) or even higher. It is crucial to consult the datasheet or manufacturer’s specifications to determine the specific temperature rating for a particular electrolytic capacitor.

11. Is cold a bad sign for capacitors?

Extreme cold temperatures can affect the performance of capacitors, particularly electrolytic capacitors. Cold temperatures can increase the resistance of the capacitor’s internal components, leading to reduced efficiency and altered electrical characteristics.

Additionally, rapid temperature changes, such as thermal cycling between extreme cold and hot conditions, can cause mechanical stress, resulting in cracks, delamination, or internal damage. It is advisable to avoid exposing capacitors to extreme cold temperatures whenever possible.

12. Why do electrolytic capacitors explode?

Electrolytic capacitors have a risk of exploding under certain conditions. This can occur if the capacitor is subjected to excessive voltage stress, temperatures beyond its specified limits, or polarity reversal.

The electrolyte inside the capacitor can break down, releasing flammable gases. If an ignition source is present, such as a spark or high temperatures, the combination of flammable gases and the ignition source can lead to an explosion.

Proper handling, adherence to voltage and temperature limits, and avoiding reverse polarity are essential to prevent such incidents.

13. What temperature should the capacitor be stored at?

The recommended storage temperature for capacitors varies depending on their type and construction. In general, capacitors should be stored in a cool, dry environment within their specified temperature range. This range can typically be found in the manufacturer’s datasheet or specifications.

Storing capacitors outside their recommended temperature range can lead to changes in capacitance, increased leakage currents, or degradation of the internal components, compromising their performance and longevity.

14. Does the capacitor change with temperature?

Yes, capacitors can be affected by temperature changes. The capacitance value of a capacitor can vary with temperature. Different capacitor types have different temperature coefficients, which describe how the capacitance changes with temperature.

For example, ceramic capacitors typically have a positive temperature coefficient, meaning that their capacitance increases with rising temperatures.

On the other hand, some electrolytic capacitors may have a negative temperature coefficient, resulting in a decrease in capacitance as the temperature increases. It is important to consider temperature effects when designing circuits that require precise capacitance values.

15. Do capacitors smoke?

Under normal operating conditions, capacitors should not emit smoke. However, in certain cases of severe failure or electrical overstress, capacitors can exhibit smoke or release gases. This can occur due to internal component damage, excessive heat, or breakdown of the dielectric material. The presence of smoke indicates a potential hazardous situation, and immediate action should be taken to shut down the circuit and ensure personal safety.

16. Does humidity affect capacitors?

Humidity can affect capacitors, particularly those with exposed terminals or those operating in high humidity environments.

Moisture or high humidity levels can lead to corrosion, which can deteriorate the terminals and connections of capacitors.

Corrosion can increase the resistance and degrade the electrical performance of the capacitor.

Additionally, humidity can affect the dielectric material, altering its properties and potentially causing changes in capacitance values. It is important to choose capacitors specifically designed for humid conditions or implement proper protection measures to mitigate the impact of humidity.

Useful Video: Hummel run capacitor getting hot.

References

- https://www.kalosflorida.com/air-conditioning/why-do-capacitors-fail/

- https://www.electrocube.com/pages/why-capacitors-fail-technical-bulletin

- https://www.electronics-tutorials.ws/capacitor/cap_3.html

- https://electronics.stackexchange.com/questions/51645/should-electrolytic-capacitors-get-hot

- https://www.yuden.co.jp/eu/product/support/faq/q015.html

- https://www.diyaudio.com/community/threads/capacitors-get-hot.112748/

- https://www.electronicsweekly.com/blogs/engineer-in-wonderland/capacitors-getting-hot-2020-08/

- https://forum.allaboutcircuits.com/threads/the-capacitors-are-warming-up-become-hot.137295/

- https://maker.pro/forums/threads/does-inductor-and-capacitor-get-heated.293902/

- https://groupdiy.com/threads/is-it-ok-for-can-type-capacitors-to-get-hot.19366/

Leave a Reply