Carbon fiber is an incredible material that has taken the world by storm! From automotive to aerospace, this lightweight yet incredibly strong material has revolutionized how we build and design things. But one factor that’s often overlooked when it comes to carbon fiber is its conductivity – can it carry electricity? In this definitive guide on carbon fiber conductivity, we’ll dive deep into this question and provide you with useful tips and insights so you can make an informed decision about whether or not carbon fiber is a conductor for your project.

What are Conductors?

Conductors are essential components of any electronic circuit or network of circuits, allowing electricity to flow easily between components and helping to regulate the amount of current flowing through a device.

Conductors can be classified into two categories: conductive metals and non-conductive insulators. The most common type of metal conductor is copper, which is widely used in electrical wiring due to its excellent conducting properties. Other metals commonly used for conducting include silver, gold, aluminum, and tin. Non-metallic materials like plastics and ceramics are also used as conductors, but they typically have lower conductivity than metals.

The way in which electrons move through a conductor depends on its atomic structure and arrangement. In pure metal conductors, such as copper or aluminum, electrons move freely from one atom to another without having to break any bonds between them.

When electricity flows through a conductor, it can cause the material to heat up. This is why electrical wiring needs to be insulated with materials like rubber and PVC to prevent any accidents from occurring due to overheating. Conductors are also used in antennas and other components for transferring, transmitting or receiving signals.

What is a Carbon Fiber

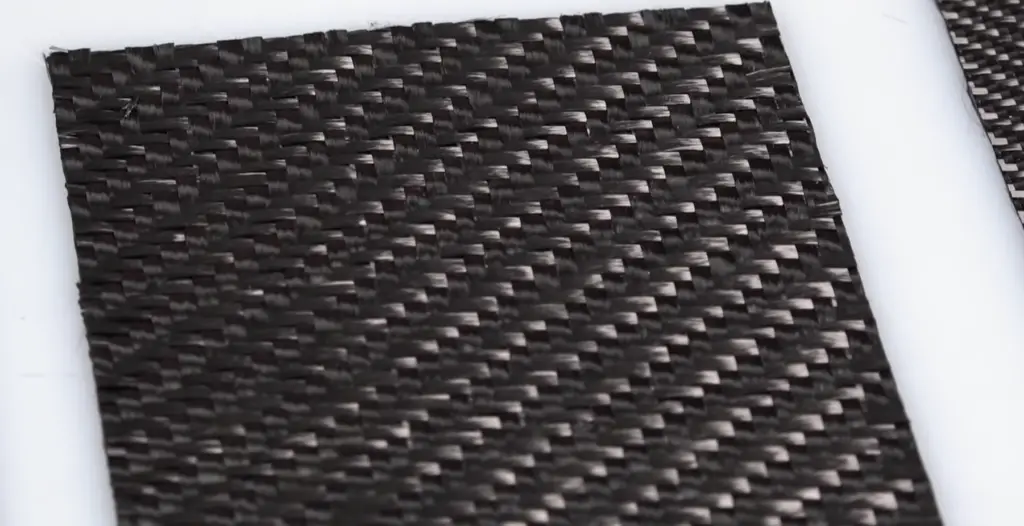

Carbon fiber is a strong and lightweight material made from thin strands of carbon, typically combined with a plastic resin to create composite materials. It’s often used in industries such as aerospace, automotive, sporting goods, and robotics due to its high strength-to-weight ratio and many other advantageous properties.

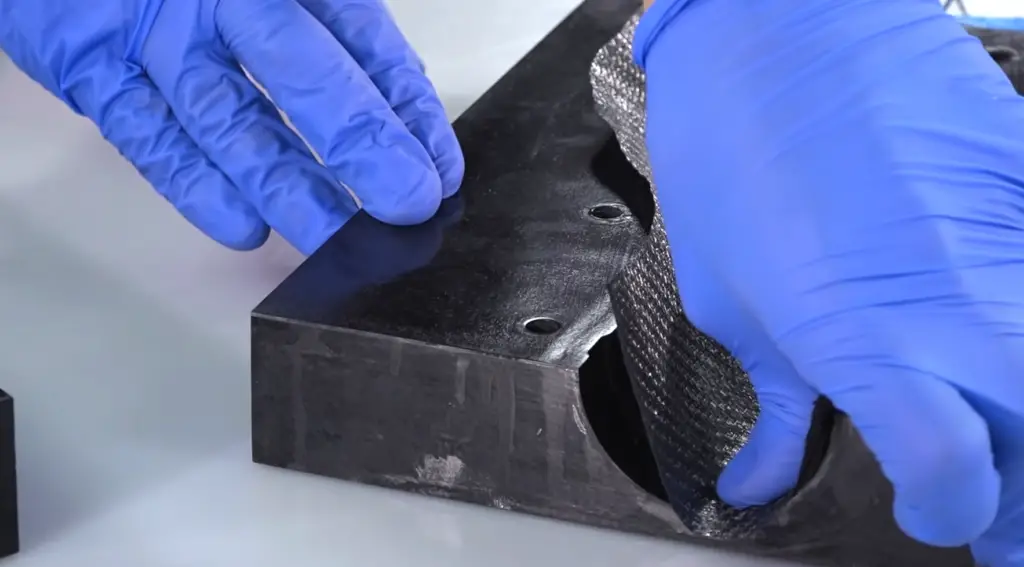

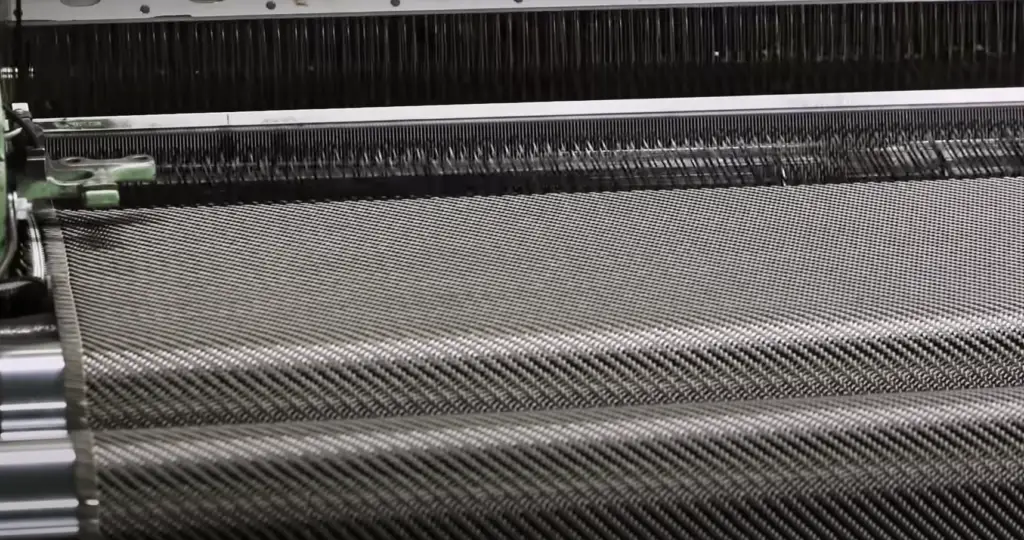

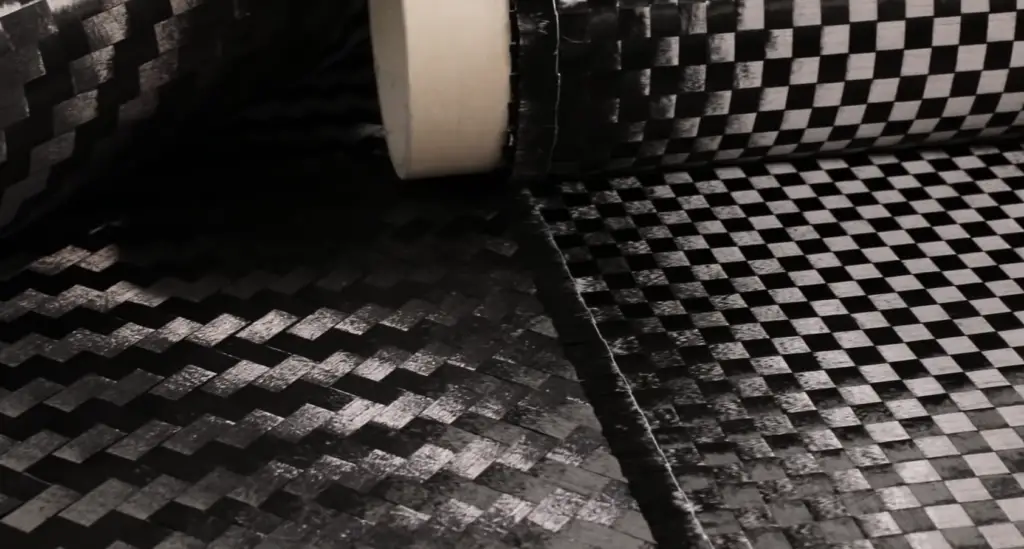

The manufacturing process of carbon fiber starts by taking raw materials (such as polyacrylonitrile or PAN) and spinning it into long fibers. These fibers are then treated with heat and stretched to align them along the same axis before being woven into cloth-like fabrics. The final step involves combining the fabric with a resin matrix which hardens when cured under pressure. This results in stiffer structures that possess superior tensile strength, stiffness and low thermal expansion.

Surface treatment is also a part of carbon fiber manufacturing, as it’s used to add functional properties such as electrical conductivity or thermal insulation. These treatments can be applied through processes such as plasma coating, chemical vapor deposition (CVD), and atomic layer deposition (ALD).

However, when surface treatments are added to carbon fiber, it can become an effective conductor. Treatments like plasma coating and CVD help to increase the size of individual fibers so that electricity can flow more easily.

Carbon fiber is significantly stronger than steel but much lighter in weight, making it an ideal material for many applications that require a combination of high strength and lightness such as airplane components, sporting equipment, and racing cars. Carbon fiber also has excellent fatigue resistance, meaning it doesn’t become brittle or break easily from repeated use. It’s also resistant to corrosion and chemical damage, making it a great choice for outdoor applications. [1], [2]

How Conductive are Carbon Fibers

While carbon on its own is very conductive, the process of creating carbon fiber makes it non-conductive. However, by adding a surface treatment like plasma coating or CVD, the fibers can become conductive again and be used in electrical applications.

This applies to both thermal and electrical conductivity. With the right surface treatment, carbon fiber can be used to transfer and dissipate heat as well as electrical current. Compared to metal conductors, carbon fiber has far lower thermal conductivity, but higher electrical resistance which makes it an ideal choice for many applications requiring high-temperature and high-voltage conditions.

The fault is particularly in the 3D arrangement of graphene sheets not being regular enough to provide a path for electrons to flow continuously and not in the nature of the individual graphene sheets themselves. This means that carbon fiber can be made conductive provided surface treatments are applied, although it will never match the conductivity of metals like copper or aluminum. [1], [2], [3]

How Can We Make Carbon Fiber More Conductive

As you can see, carbon fiber by itself is not a good conductor. However, it can be made conductive and used in many electrical applications with the right treatments.

Turbostratic layer arrangement

The most effective way to increase the conductivity of carbon fibers is to use a turbostratic layer arrangement. This involves using layered graphene sheets with misaligned edges, which causes electrons to jump from one sheet to another instead of flowing in a continuous path. The result is an increase in electrical conductivity without sacrificing any of its other advantages such as thermal insulation or strength.

When treated with this arrangement, carbon fiber can be made more conductive than copper and aluminum while still maintaining its light weight and strength. This makes it ideal for applications that require high heat resistance and electricity conduction like electric vehicle motors and laptops.

Use of reinforcing materials

The use of reinforcing materials can greatly increase the conductivity of carbon fiber. For example, when aluminum or stainless steel wires are added to a composite material made with carbon fiber, its overall electrical resistance is reduced significantly. This makes it an ideal choice for applications requiring high levels of conductivity such as in grounding systems and high-voltage wiring.

Additionally, other materials such as graphite powder, which has higher thermal conductivity than carbon fibers, can be added to accelerate heat dissipation in electronics and other heat-sensitive components.

Of course epoxy resins also play an important role in the conductivity of carbon fiber, as the epoxy matrix acts as a bridge between individual fibers, allowing electrons to flow through them.

Finally, ceramics and metals can also be used to create conductive pathways in carbon fiber composites, adding strength and durability while improving the material’s overall electrical properties.

Use of interfacial enhancers

A similar technique is the use of interfacial enhancers. These are materials with strong adhesion properties that can be used as a glue between individual fibers and epoxy resins, allowing electrons to flow more easily through the composite material.

The most commonly used materials are graphite nanotubes and carbon nanofibers, which have been found to improve the electrical conductivity of carbon fiber composites by a lot! [1], [2], [3]

Applications of Carbon Fibers

As you can see, there are many ways to enhance the conductivity of carbon fiber. This makes it an ideal choice for many applications that require high levels of electricity conduction and thermal insulation, such as electric motors, laptops, and grounding systems. In this section we will discuss some of the most common applications of carbon fiber.

Aircraft sector

One of the most popular applications for carbon fiber is in the aircraft sector. Carbon fiber composites are lighter yet stronger than traditional metals, and their excellent thermal insulation properties make them a great choice for building fuselages, wings and other components of airplanes. Additionally, because of their high electrical conductivity they can be used to build aircraft wiring systems as well.

Aerospace and marine industry

The aerospace and marine industry has been using carbon fiber for many years now, mostly due to its high strength-to-weight ratio. Carbon fiber composites are often used in aircraft wings, helicopter blades, and other structural components. They also have great corrosion resistance and can withstand extreme temperatures, making them ideal for use in applications that require these characteristics.

Automotive industry

The automotive industry has been increasingly using carbon fiber composites in recent years due to their strength-to-weight ratio, which can improve fuel efficiency significantly. Carbon fiber is also used as a replacement for steel and aluminum components, as it is lighter yet just as strong or even stronger than these materials. Additionally, its electrical properties makes it perfect for use in hybrid and electric vehicles, where the motor must be able to withstand high levels of electricity without overheating.

EMI shielding

EMI shielding is also an important application of carbon fiber composites. The material’s electrical properties make it perfect for use in EMI shields, as it can resist electrostatic discharges and provide insulation against electromagnetic radiation. Furthermore, its superior durability makes it ideal for use in applications requiring long-term protection from these types of fields.

Sporting equipment

Carbon fiber is also often used in the manufacture of sporting equipment due to its light weight and strength. It is particularly popular in cycling and kayaking, where it can be used to make lighter and stronger frames for bicycles and boats.

Textile machinery

Textile machinery is another industry that relies heavily on carbon fiber composites. These materials are used to manufacture lightweight and high-strength components such as spindles, reelers, and bobbins. Additionally, their electrical properties make them ideal for use in textile machines that require high levels of electricity conduction and insulation, such as spinning frames or winding machines.

Accessories

Besides its practicality, carbon fiber is also a popular choice for use in jewelry and other accessories. Its unique texture and high gloss finish make it perfect for creating stylish items that are sure to stand out from the crowd. Furthermore, because of its superior electrical properties, carbon fiber can be used to create electronics-based accessories such as earbuds or smartwatches.

Electric current transmission

While this is a pretty niche application, carbon fiber composites have also been used for electric current transmission. The material’s excellent electrical conductivity makes it perfect for this purpose, as it allows for the efficient transfer of energy with minimum losses. Additionally, its superior durability and resistance to corrosion make it ideal for use in applications requiring long-term stability and reliability.

Décor and interior design

Carbon fiber composites have also been used in décor and interior design applications. The material’s unique texture and high gloss finish make it perfect for creating stylish furniture, as well as a variety of other decorative items such as sculptures, vases, and wall panels. Additionally, carbon fiber is an excellent choice for use in electrical components, making it an ideal material for lighting fixtures and other electronics-based products that require insulation or conduction.

Overall, carbon fiber is an extremely versatile material that can be used in a variety of applications thanks to its combination of strength-to-weight ratio and electrical properties. While there are many more uses out there, the above mentioned ones are some of the most common ones you’re likely to come across in your day-to-day life. [1], [3], [4]

FAQ

What are 3 properties of carbon fiber?

- High Tensile Strength: Carbon fibers have an extremely high tensile strength, meaning they can resist a large amount of force before breaking or deforming. This makes them ideal for applications where strength and durability are needed, such as aerospace and automotive components.

- Lightweight: Carbon fibers have an incredibly low density, which means that it takes up very little space compared to other materials with the same strength. This makes carbon fiber perfect for lightweight designs where weight needs to be kept at a minimum without sacrificing structural integrity.

- Low Thermal Expansion: Carbon fibers have a very low thermal expansion coefficient, meaning that the material does not change shape when exposed to changes in temperature. This is important for certain applications where precise dimensional control is needed, such as medical implants and other precision engineering designs.

Is carbon fiber a conductor?

No, carbon fiber is not an electrical conductor. The material’s unique properties, such as its low thermal expansion coefficient and strength-to-weight ratio, make it ideal for many applications where electrical conductivity is not required. Carbon fibers are still used in applications where electrical current needs to be conducted, but they must be coupled with another material that can act as a conduit of electricity.

Is carbon fiber conductive when compared to metal?

The answer to this question is a bit complicated.

This is because it is a non-metallic material with relatively poor thermal and electrical conductivity. However, there are certain types of carbon fibers that have been impregnated with metal particles or coatings, which can increase their electrical conductivity.

So when comparing carbon fiber to other materials, it is important to keep in mind that its conductivity is highly dependent on the type of fiber and treatment used. In general, carbon fiber provides good insulation and is not considered a good conductor when compared to metals. However, certain treatments can improve its electrical properties, making it more suitable for certain applications.

Is carbon fiber electrical conductive?

No, carbon fiber is not an electrical conductor. It is composed of tightly-bound carbon atoms and therefore does not contain any free electrons to carry electrical current. Carbon fibers may sometimes be used as part of a composite material in order to improve its electrical properties, but the actual carbon fiber will remain non-conductive.

What are some common uses for carbon fiber?

Carbon fiber is known for its strength and lightweight, making it ideal for use in a number of applications like aerospace engineering, automotive design, sporting goods, musical instruments, architecture and consumer electronics. It has been used to create strong lightweight frames for bicycles, aircrafts and sailing boats; durable body panels for cars; reinforced parts for drones; and cases for high-end mobile phones. It has also been used to create sculptures, furniture and other decorative items.

Are carbon fiber good conductors?

The short answer is: no, carbon fiber is an insulator. This means that it does not conduct electricity or heat very well.

Carbon fibers are made up of many small strands of graphite and other materials that are intertwined together to make the fiber strong and lightweight. The strands themselves don’t conduct electricity or heat, so when they’re arranged in a pattern (as in carbon fiber), the overall material will also be an insulator.

That said, there are some special types of carbon fiber which have been designed with metal particles mixed into them, which can increase their conducting properties. However, these are not common and most carbon fibers used for industrial purposes remain nonconductive materials.

For many applications, the insulation properties of carbon fiber are a benefit, since it can help prevent electrical shorts and keep items from overheating. It’s also relatively lightweight and strong, making it useful for a variety of other purposes including construction, aerospace engineering and automotive manufacturing.

Is carbon fiber an insulator?

Yes, carbon fibers are an insulator. This is because of the molecular structure of carbon fibers. They consist of tightly-bonded layers of graphene that prevent electricity from flowing freely, resulting in a material that does not conduct electrical current. In contrast, metals are excellent conductors because they contain free electrons that can easily be moved by an applied electric field or voltage. Carbon fiber has no free electrons to move and therefore it has very low electrical conductivity compared to metal.

Moreover, depending on the type of carbon fiber used and the other materials present in its composite construction, some carbon fiber composites might even exhibit high levels of insulation to thermal energy as well. This makes them ideal for use in applications where extreme temperatures need to be regulated.

Why is carbon not a good conductor?

Carbon fiber is not a good conductor because it has low electrical conductivity, meaning the electrons flow more slowly through it than other substances. This is due to the irregular stacking of graphene sheets, which are the basic units of carbon fiber. The graphene sheets contain sp2 bonds in which three electrons from each atom travel along one single plane and do not bridge with the other atoms. This prevents electrical conduction and limits the speed at which electrons can move through the material.

Furthermore, carbon fibers have a high resistivity due to their non-uniform structure. This is because as the number of layers increases, so does the distance between them, leading to more resistance. Additionally, some types of carbon fibers have a coating of compounds like silicon dioxide or aluminum oxide that further increase their resistivity. As such, it is not an ideal material for conducting electricity since its resistivity is much higher than metals like copper or silver.

Useful Video: Carbon fibre electrical conductivity MVI 5923

Conclusion

Conductors are materials that can easily allow the flow of electrons. They are usually made of metals like copper, silver, gold and aluminum. However, carbon fiber is not a good conductor in the slightest.

While carbon fiber is not a conductor, it can serve as an insulating material. It has become increasingly popular in many industries because of its low weight and high strength. Carbon fiber is corrosion-resistant and, when combined with a conductive coating or other materials, can be used to create components that are electrical conductors. Electrical engineers should consider the benefits carbon fiber offers in their designs. Its light weight and strength make it suitable for many applications where traditional metallic materials may not be feasible or as effective. With proper care and maintenance, carbon fiber products will provide years of reliable service under typical conditions.

However, due to its unique physical properties, it’s important to investigate compatibility with existing electrical systems before integrating carbon fiber into an application.

Thanks for reading! Our guide has provided useful information to help you determine whether or not carbon fiber is right for your project. With the right combination of materials, carbon fiber can be used in applications where traditional conductors would ordinarily be unable to provide optimal performance.

References

- https://carbonfibergear.com/blogs/carbonfiber/is-carbon-fiber-conductive

- https://www.mdpi.com/2076-3417/9/11/2390

- https://techiescientist.com/does-carbon-fiber-conduct-electricity/

- https://smicomposites.com/top-5-important-uses-of-carbon-fiber-sheets/

Leave a Reply